Difference between revisions of "VTube-LASER"

(→Videos) |

(→Videos) |

||

| Line 17: | Line 17: | ||

== Videos == | == Videos == | ||

| − | * See the [[VTube-LASER Videos]] page | + | * [[image:vtube-laser_video_6inch_tube.jpg|70px]]See the [[VTube-LASER Videos]] page |

* [[image:cisco_webex.jpg|70px]][[Cisco Webex]] Live Demonstrations | * [[image:cisco_webex.jpg|70px]][[Cisco Webex]] Live Demonstrations | ||

<br> | <br> | ||

Revision as of 13:05, 28 February 2013

|

|

Videos

-

See the VTube-LASER Videos page

See the VTube-LASER Videos page

-

Cisco Webex Live Demonstrations

Cisco Webex Live Demonstrations

Software Updates

- See the VTube Software Updates page

- See the VTube Features Soon to Be Released page

- See the VTube Software Maintenance Plan page

Executive Summary

VTube-LASER Description

|

VTube-LASER uses the laser scanner and/or ball probe to:

VTube-LASER ClientsExamples of actual clients:

|

List of Benefits of Using VTube-LASER for Tube Measurement

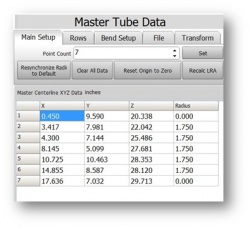

Benefit 1 - Super Quick Project SetupOther measurement programs are often more generic in their approach to geometry. In order to measure a tube, it is necessary to build up individual elements and create a script for the process. |

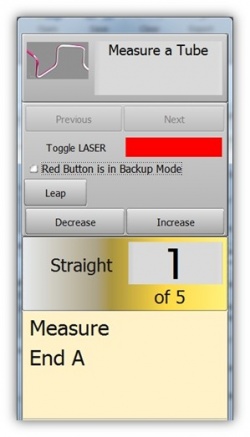

Benefit 2 - Built-in Automated Process for Measuring TubesYou don't have to guess at the order of the steps to measure a tube. When you measure a tube with VTube, the methods for gathering the information and calculating the centerline, intersection points, and bend data are preprogrammed as a series of consistent steps that never change and never have to be scripted. |

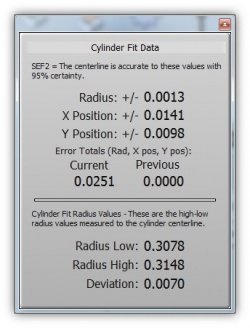

Benefit 3 - Built in Feedback to Increase Confidence in the DataVTube-LASER has special procedures that help anticipate the level of confidence you will have in the incoming data. There are series of crosschecks just for measuring tubing, both mathematical and on-screen, that allow users to know if the data is good. |

Benefit 4 - Built-in Bender CorrectionVTube-LASER knows how to correct benders - and has special menus and procedures for doing that well. |

Tutorials and Information

- How VTube Handles Data Storage for Multiple User Logins

- Damping Bender Corrections with VTube-LASER

- How to Activate the VTube-LASER Hardware Key

- How to Setup VTube-LASER for the Network License Manager

- Recommended VTube-LASER Screen Resolution

- How to Measure a short end-straight with a flange

- How to Change the default linear units in VTube

- Recommended VTube Computer Specification

- How we connect VTube-LASER to Eaton Leonard Benders - Premier,EL-2000, and VE-LOG

- Explain Sigma as it relates to errors.

- End-Scan Technique Research

- Surface Coating for LASER Scanning

- Technical Document: How to Measure Copper Tube with a FARO Edge Scanner

- How to Convert from TubeCalc Elongation to VTube Elongation

- VTube-LASER Model Colors

- How to find the VTube Bender Template Location

- Best-Fit Alignment Versus Hard-Point Alignment

- How to check OpenGL Drivers versions

- How to Measure Large Diameter Tubing

- How to Setup Reports to Show Bender Plus Adjusted Data

- See Measuring Center Accessories for turnkey components recommended

- How to Adjust the VTube License Type in the Config File

- How to Set the Number of Values Beyond the Decimal for VTube

- How to Change the VTube User Interface Language

- How to Change the VTube Default Setup

- How to Import the Split Bend with STEP Version of "VTube-LASER Demo CAD Model 2"

- How to find the VTube configuration files

- How to copy the VTube configuration files for different Windows user logins

- See how CAM2 can work with VTube-LASER to measure components around tube shapes. See FARO CAM2

VTube Related Program IDs Used for Licensing

| PID | Program Licensed | |

|---|---|---|

| 354 | VTube-STEP | |

| 355 | VTube-Pro | |

| 356 | VTube-LASER | |

| 360 | VTube-LASER Programmer | |

Other Pages

- VTube-LASER Home Web Page

- Read the VTube Software License

- Recommended CAD Conversion Tools

- Measuring Center Accessories