Difference between revisions of "CNC Bender v11-20080424"

| (48 intermediate revisions by one user not shown) | |||

| Line 1: | Line 1: | ||

| − | [image: | + | [[image:Cncbender_logo_pushbending.png]] |

[[image:Operatorstation_model.jpg|right]] | [[image:Operatorstation_model.jpg|right]] | ||

__TOC__ | __TOC__ | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | =CHANGES to CNC BENDER: Push Bending= | + | |

| + | =CHANGES to CNC BENDER: [[Push Bending]]= | ||

===[[image:Check.jpg|25px]] NEW - Push Bending Profile Setup Button === | ===[[image:Check.jpg|25px]] NEW - Push Bending Profile Setup Button === | ||

| − | This new feature allows CNC Bender to push-bend a tube through rollers to achieve very large radius bends on a bender. The new feature is controlled with the Push Bend Profile Setup menu that is accessed through the FRB page. | + | [[image:Cncbender_v11_pushbend_button.jpg|300px|right]] |

| + | [[image:Cncbender_v11_pbprofile_close.png|left]] This new feature allows CNC Bender to push-bend a tube through rollers to achieve very large radius bends on a bender. The new feature is controlled with the Push Bend Profile Setup menu that is accessed through the FRB page. | ||

<br><br> | <br><br> | ||

| − | Push-bending is achieved using roller dies rather than clamps and pressure dies. The tube is pushed by the carriage through the rollers. The bend arm is rotated to a position that will cause the tube to form into a large radius. The more angle on the bend arm, the smaller the resulting radius. This allows standard benders to create radius values much larger than is possible with draw bending alone. | + | Push-bending is achieved using roller dies rather than clamps and pressure dies. The tube is pushed by the carriage through the rollers. The bend arm is rotated to a position that will cause the tube to form into a large radius. The more angle on the bend arm, the smaller the resulting radius. This allows standard benders to create radius values much larger than is possible with draw bending alone.<br><br> |

| − | + | ||

<br><br> | <br><br> | ||

| − | ===[[image:Check.jpg|25px]] NEW - Push Bending Profile Setup Menu === | + | ===[[image:Check.jpg|25px]] NEW - Push Bending Profile Table Setup Menu === |

| − | The setup is performed in this menu: | + | The setup is performed in this menu:<br><br> |

| + | [[image:Cncbender_v11_pushbend_profilesetup.jpg|300px]] | ||

<br><br> | <br><br> | ||

| − | [[image: | + | Each profile row contains a profile setup for a given radius. An unlimited number of profile values can be entered. Read more about how the [[Push Bending Profile Table]] works. Using this method of calculation, it is possible to calculate different Push Bends by indicating the bend angle. |

| + | |||

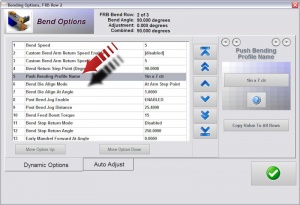

| + | ===[[image:Check.jpg|25px]] NEW - Push Bending Profile Name Dynamic Option - Bend Options === | ||

| + | The bend options now include a new dynamic option that will allow you choose one of the push bend profile names.<br><br> | ||

| + | [[image:Cncbender_v11_pushbend_bendoptions.jpg|300px]] | ||

<br><br> | <br><br> | ||

| − | |||

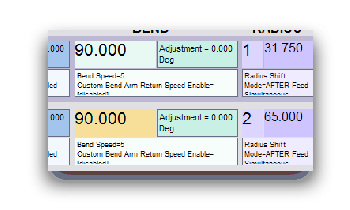

| − | + | ===[[image:Check.jpg|25px]] NEW - Push Bending Profile Enable - Color Indicator === | |

| − | + | The bend option field changes color when you select a push bend profile in the bender options.<br><br> | |

| − | + | [[image:Cncbender_v11_colorcells_close.png|350px]]<br><br> | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | [[image:Cncbender_v11_pushbend_optionfieldcolor.jpg|300px]] | |

| − | + | ||

| − | |||

| − | |||

| − | |||

<br><br> | <br><br> | ||

| − | |||

===[[image:Check.jpg|25px]] NEW - Push Bending Profile Enable - Low Level === | ===[[image:Check.jpg|25px]] NEW - Push Bending Profile Enable - Low Level === | ||

| − | + | ||

| − | The low level option is a safety feature that disables all push-bending until the feature is enabled. | + | The low level option is a safety feature that disables all push-bending until the feature is enabled.<br><br> |

| − | [[image: | + | |

| + | [[image:Cncbender_v11_pushbend_lowlevel.jpg|300px]] | ||

| + | |||

<br><br> | <br><br> | ||

| Line 53: | Line 48: | ||

*Back to [[CNC Bender]] | *Back to [[CNC Bender]] | ||

*Back to [[CNC Bender Software Updates]] | *Back to [[CNC Bender Software Updates]] | ||

| − | + | *Read about [[Push Bending]] | |

| − | + | *Read about [[Push Bend Profile Table]]s | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | [[ | + | |

Latest revision as of 23:03, 17 July 2008

Contents |

CHANGES to CNC BENDER: Push Bending

NEW - Push Bending Profile Setup Button

NEW - Push Bending Profile Setup Button

This new feature allows CNC Bender to push-bend a tube through rollers to achieve very large radius bends on a bender. The new feature is controlled with the Push Bend Profile Setup menu that is accessed through the FRB page.

Push-bending is achieved using roller dies rather than clamps and pressure dies. The tube is pushed by the carriage through the rollers. The bend arm is rotated to a position that will cause the tube to form into a large radius. The more angle on the bend arm, the smaller the resulting radius. This allows standard benders to create radius values much larger than is possible with draw bending alone.

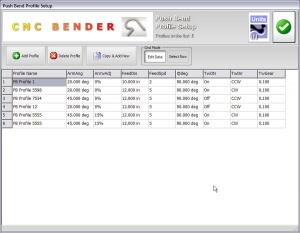

NEW - Push Bending Profile Table Setup Menu

NEW - Push Bending Profile Table Setup Menu

The setup is performed in this menu:

Each profile row contains a profile setup for a given radius. An unlimited number of profile values can be entered. Read more about how the Push Bending Profile Table works. Using this method of calculation, it is possible to calculate different Push Bends by indicating the bend angle.

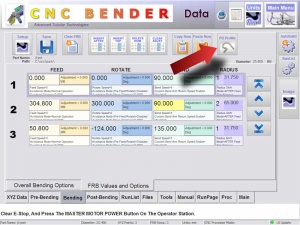

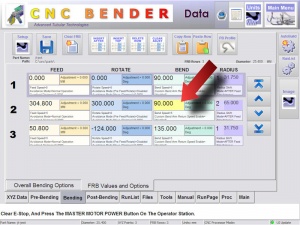

NEW - Push Bending Profile Name Dynamic Option - Bend Options

NEW - Push Bending Profile Name Dynamic Option - Bend Options

The bend options now include a new dynamic option that will allow you choose one of the push bend profile names.

NEW - Push Bending Profile Enable - Color Indicator

NEW - Push Bending Profile Enable - Color Indicator

The bend option field changes color when you select a push bend profile in the bender options.

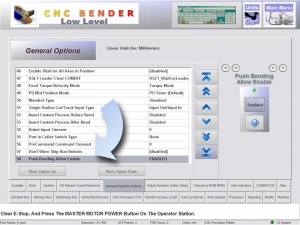

NEW - Push Bending Profile Enable - Low Level

NEW - Push Bending Profile Enable - Low Level

The low level option is a safety feature that disables all push-bending until the feature is enabled.

Other Pages

- Back to CNC Bender

- Back to CNC Bender Software Updates

- Read about Push Bending

- Read about Push Bend Profile Tables