Difference between revisions of "VTube-LASER v2.9"

(→25px NEW: IMPORT MULTIPLE SUPRAVISION FILES) |

(→25px OTHER CHANGES) |

||

| (36 intermediate revisions by one user not shown) | |||

| Line 6: | Line 6: | ||

==Revision 2.9== | ==Revision 2.9== | ||

| − | + | Release Date: November 1, 2017<br> | |

| − | + | ||

* Back to [[VTube-LASER]] | * Back to [[VTube-LASER]] | ||

| Line 22: | Line 21: | ||

</table> | </table> | ||

| − | + | __NOTOC__ | |

| + | |||

| + | ==[[image:Check.jpg|25px]] MAJOR NEW FEATURE: ASSEMBLY== | ||

| + | |||

| + | <table cellpadding=10 width=1100> | ||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | VTube now allows you to include multiple tubes in a single project.<br><br> | ||

| + | * Add new tubes to existing tubes. | ||

| + | * Measure all the tubes together or separately. | ||

| + | * Align all the tubes at the same time or separately. | ||

| + | |||

| + | <h3>See video 75 in the [[VTube-LASER Videos]] page</h3> | ||

| + | |||

| + | <td> | ||

| + | [[image:vtube-laser_v2.9_assembly_hvac_tubes.png|600px]]<br><br> | ||

| + | |||

| + | </td> | ||

| + | <td> | ||

| + | </tr> | ||

| + | </table> | ||

| + | |||

| + | |||

| + | <table cellpadding=10 width=1100> | ||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | We reverse-engineered this entire assembly in about 30 minutes. | ||

| + | <td> | ||

| + | [[image:vtube-laser_v2.9_motorcycle_pipe_assembly.png|600px]] | ||

| + | </td> | ||

| + | <td> | ||

| + | </tr> | ||

| + | </table> | ||

| + | <br><br> | ||

| + | |||

==[[image:Check.jpg|25px]] MAJOR ENHANCEMENT: END SCANNING IS MUCH IMPROVED== | ==[[image:Check.jpg|25px]] MAJOR ENHANCEMENT: END SCANNING IS MUCH IMPROVED== | ||

| Line 33: | Line 66: | ||

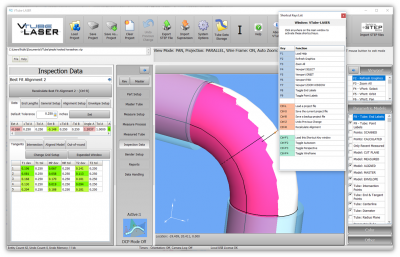

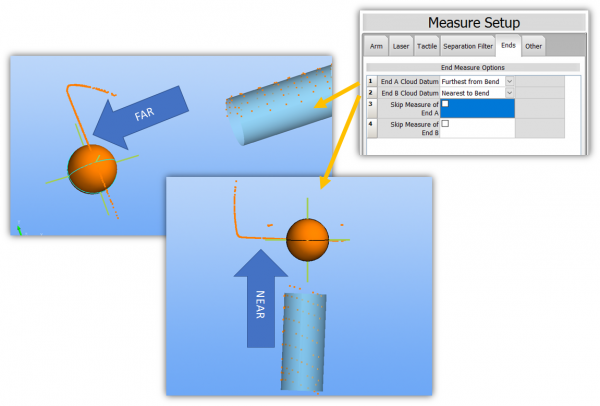

* It is much faster and more reliable than previous versions.<br><br> | * It is much faster and more reliable than previous versions.<br><br> | ||

* It can now find the furthest point or the nearest point - or even the centroid of the end-scan cloud in the scan.<br><br> | * It can now find the furthest point or the nearest point - or even the centroid of the end-scan cloud in the scan.<br><br> | ||

| − | * It draws linear dimensions showing the endpoint offsets - including the ball probe compensation offset.<br><br> | + | * It draws linear dimensions showing the endpoint offsets - including the ball probe compensation offset. (See the next section.)<br><br> |

| − | * The obsolete End Scan Tolerance restriction is removed.<br><br> | + | * The obsolete End Scan Tolerance restriction is removed (See the section below).<br><br> |

| − | * A new END measure was added to MEASURE SETUP to control the new settings. | + | * A new END measure was added to MEASURE SETUP to control the new settings.<br><br> |

| + | * Improved measuring instructions show what to expect when trimming data in end scans.<br><br> | ||

[[image:vtube-laser_v2.9_endscan_better_instructions.png|300px]] | [[image:vtube-laser_v2.9_endscan_better_instructions.png|300px]] | ||

| Line 54: | Line 88: | ||

</table> | </table> | ||

| − | ==[[image:Check.jpg|25px]] | + | ==[[image:Check.jpg|25px]] NEW: END POINT DIMENSION FOR OFFSET POINTS DURING MEASUREMENT== |

<table cellpadding=10 width=1100> | <table cellpadding=10 width=1100> | ||

<tr valign=top> | <tr valign=top> | ||

<td width=300> | <td width=300> | ||

| − | VTube now | + | VTube now automatically draws a linear dimension in the viewport between the scanned point and the final offset point to confirm that the distance is correct. |

| − | + | <td> | |

| − | + | </td> | |

| − | + | <td> | |

| + | [[image:vtube-laser_v2.9_lineardimension_endoffset.png|600px]] | ||

| + | </td> | ||

| + | </tr> | ||

| + | </table> | ||

| + | <br><br> | ||

| − | |||

| − | + | ==[[image:Check.jpg|25px]] NEW: CUSTOM REPORTABLE MEASURE NOTE FOR EACH MEASURE== | |

| − | [[image: | + | |

| + | <table cellpadding=10 width=1100> | ||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | VTube-LASER allows you to enter a custom measure note before a measure. This note can then be displayed in reports. | ||

| + | <td> | ||

</td> | </td> | ||

<td> | <td> | ||

| + | [[image:vtube-laser_v2.9_measure_note.png|600px]] | ||

| + | </td> | ||

</tr> | </tr> | ||

</table> | </table> | ||

| + | <br><br> | ||

| + | |||

| + | |||

| + | |||

| + | ==[[image:Check.jpg|25px]] NEW: THE MEASURE DATE/TIME CAN BE REPORTED== | ||

<table cellpadding=10 width=1100> | <table cellpadding=10 width=1100> | ||

<tr valign=top> | <tr valign=top> | ||

<td width=300> | <td width=300> | ||

| − | + | VTube-LASER records and stores the measure date/time - and it can now be included in reports. | |

<td> | <td> | ||

| − | |||

</td> | </td> | ||

<td> | <td> | ||

| + | [[image:vtube-laser_v2.9_measure_datetime.png|600px]] | ||

| + | </td> | ||

</tr> | </tr> | ||

</table> | </table> | ||

| + | <br><br> | ||

| + | |||

| + | ==[[image:Check.jpg|25px]] REMOVED END SCAN DIAMETER TOLERANCE RESTRICTION== | ||

| + | |||

| + | <table cellpadding=10 width=900> | ||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | VTube would refuse measurements that were too far from the end of the actual diameter surface of the tube. This does nothing but frustrate end users. Sometimes it is necessary to scan points that are far from the diameter.<br><br>We removed this limitation permanently. | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:End Scan Qualification Tolerance Removed.png|600px]] | ||

| + | </td> | ||

| + | </tr> | ||

| + | </table> | ||

| + | <br><br> | ||

| + | |||

| + | ==[[image:Check.jpg|25px]] FIX: VTUBE NOW DRAWS DIAMETER EVEN WITH ZERO-LENGTH STRAIGHTS== | ||

| + | |||

| + | <table cellpadding=10 width=900> | ||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | In previous versions, zero length straights would stop the diameter from drawing.<br><br> | ||

| + | This has been fixed in build 95 of version 2.9. | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:vtube_v2.9_zerolength_straight_fix.png|600px]] | ||

| + | </td> | ||

| + | </tr> | ||

| + | </table> | ||

| + | |||

| + | <br><br> | ||

==[[image:Check.jpg|25px]] ENHANCED - Bender NUMBER in BENDER SETUP Saved and Recalled with Project File == | ==[[image:Check.jpg|25px]] ENHANCED - Bender NUMBER in BENDER SETUP Saved and Recalled with Project File == | ||

| Line 111: | Line 192: | ||

<td> | <td> | ||

[[image:vtube-laser_v2.9_removed_keep_cut_plane.png|400px]] | [[image:vtube-laser_v2.9_removed_keep_cut_plane.png|400px]] | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

</tr> | </tr> | ||

</table> | </table> | ||

| Line 137: | Line 204: | ||

* It can import multiple PRT files into a single assembly. | * It can import multiple PRT files into a single assembly. | ||

* It can batch-convert multiple PRT file into a folder of VTube project files (VTP). | * It can batch-convert multiple PRT file into a folder of VTube project files (VTP). | ||

| + | <br><br> | ||

| + | '''Note: Build 91 makes PRT batch mode conversion much faster.''' | ||

| + | <br><br> | ||

| + | '''Note: Build 95 allows for 180-degree bends in PRT files.''' | ||

| + | <br><br> | ||

</td> | </td> | ||

<td> | <td> | ||

| Line 144: | Line 216: | ||

</table> | </table> | ||

<br><br> | <br><br> | ||

| − | |||

| − | |||

| − | |||

==[[image:Check.jpg|25px]] NEW: IMPORT MULTIPLE SUPRAVISION FILES== | ==[[image:Check.jpg|25px]] NEW: IMPORT MULTIPLE SUPRAVISION FILES== | ||

| Line 157: | Line 226: | ||

* It can import multiple Supravision files into a single assembly. | * It can import multiple Supravision files into a single assembly. | ||

* It can batch-convert multiple Supravision files into a folder of VTube project files (VTP). | * It can batch-convert multiple Supravision files into a folder of VTube project files (VTP). | ||

| + | </td> | ||

<td> | <td> | ||

| + | [[image:supravsion_with_stingerarm.png|300px]] | ||

| + | </td> | ||

| + | |||

| − | |||

| − | |||

</tr> | </tr> | ||

</table> | </table> | ||

| + | <br><br><br> | ||

==[[image:Check.jpg|25px]] NEW: IMPORT MULTIPLE SOLID EDGE FILES INTO AN ASSEMBLY== | ==[[image:Check.jpg|25px]] NEW: IMPORT MULTIPLE SOLID EDGE FILES INTO AN ASSEMBLY== | ||

| Line 183: | Line 255: | ||

<tr valign=top> | <tr valign=top> | ||

<td width=300> | <td width=300> | ||

| − | There are now many more skins to choose from in System Options. | + | There are now many more user interface skins to choose from in System Options. |

</td> | </td> | ||

<td> | <td> | ||

| + | [[image:vtube-laser_v2.9_skins.png|600px]] | ||

</td> | </td> | ||

</tr> | </tr> | ||

| Line 205: | Line 278: | ||

</table> | </table> | ||

<br><br> | <br><br> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

==[[image:Check.jpg|25px]] NEW: MADE CHANGES FOR FARO USB DRIVER VERSION 6== | ==[[image:Check.jpg|25px]] NEW: MADE CHANGES FOR FARO USB DRIVER VERSION 6== | ||

| Line 226: | Line 287: | ||

</td> | </td> | ||

<td> | <td> | ||

| + | [[image:FARO_usb_v6.png|600px]] | ||

</td> | </td> | ||

</tr> | </tr> | ||

| Line 247: | Line 309: | ||

</td> | </td> | ||

<td> | <td> | ||

| + | [[image:usbflash.png|300px]]<br><br> | ||

[[image:vtube-laser_svnet_nowait.png|600px]] | [[image:vtube-laser_svnet_nowait.png|600px]] | ||

</td> | </td> | ||

| Line 253: | Line 316: | ||

==[[image:Check.jpg|25px]] OTHER CHANGES== | ==[[image:Check.jpg|25px]] OTHER CHANGES== | ||

| − | + | ||

| − | + | * Build 98: The DCP (Diameter Cut Plane) now saves to project files and the default project file. | |

| − | + | * Build 98: We reverted back to the correct scanning sound from the previous version. (This version accidentally included an experimental sound. Customers don't like it!) | |

* The PREVIOUS feature that steps back in the measurement step during measurement had some serious bugs. They are fixed. '''(NOTE: Do not use the "Previous" command in earlier versions.)''' | * The PREVIOUS feature that steps back in the measurement step during measurement had some serious bugs. They are fixed. '''(NOTE: Do not use the "Previous" command in earlier versions.)''' | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

<br><br> | <br><br> | ||

Latest revision as of 04:36, 15 November 2017

|

Revision 2.9Release Date: November 1, 2017

|

MAJOR NEW FEATURE: ASSEMBLY

MAJOR NEW FEATURE: ASSEMBLY

|

VTube now allows you to include multiple tubes in a single project.

See video 75 in the VTube-LASER Videos page |

|

We reverse-engineered this entire assembly in about 30 minutes. |

MAJOR ENHANCEMENT: END SCANNING IS MUCH IMPROVED

MAJOR ENHANCEMENT: END SCANNING IS MUCH IMPROVED

|

The end-scan engine is completely redesigned in version 2.9

This change alone is worth the upgrade.

|

NEW: END POINT DIMENSION FOR OFFSET POINTS DURING MEASUREMENT

NEW: END POINT DIMENSION FOR OFFSET POINTS DURING MEASUREMENT

|

VTube now automatically draws a linear dimension in the viewport between the scanned point and the final offset point to confirm that the distance is correct. |

NEW: CUSTOM REPORTABLE MEASURE NOTE FOR EACH MEASURE

NEW: CUSTOM REPORTABLE MEASURE NOTE FOR EACH MEASURE

|

VTube-LASER allows you to enter a custom measure note before a measure. This note can then be displayed in reports. |

NEW: THE MEASURE DATE/TIME CAN BE REPORTED

NEW: THE MEASURE DATE/TIME CAN BE REPORTED

|

VTube-LASER records and stores the measure date/time - and it can now be included in reports. |

REMOVED END SCAN DIAMETER TOLERANCE RESTRICTION

REMOVED END SCAN DIAMETER TOLERANCE RESTRICTION

|

VTube would refuse measurements that were too far from the end of the actual diameter surface of the tube. This does nothing but frustrate end users. Sometimes it is necessary to scan points that are far from the diameter. |

FIX: VTUBE NOW DRAWS DIAMETER EVEN WITH ZERO-LENGTH STRAIGHTS

FIX: VTUBE NOW DRAWS DIAMETER EVEN WITH ZERO-LENGTH STRAIGHTS

|

In previous versions, zero length straights would stop the diameter from drawing. |

ENHANCED - Bender NUMBER in BENDER SETUP Saved and Recalled with Project File

ENHANCED - Bender NUMBER in BENDER SETUP Saved and Recalled with Project File

|

Customers that have many benders prefer to have the bender number saved in the project file because it is normal to associate the project with a bender.

|

ENHANCED - REMOVED "KEEP CUT PLANE" DIALOG

ENHANCED - REMOVED "KEEP CUT PLANE" DIALOG

|

Customers never choose any other option than to keep the current cut plane, so we removed this dialog to save time. |

NEW: IMPORT VECTOR LASERVISION PRT FILES

NEW: IMPORT VECTOR LASERVISION PRT FILES

|

VTube-STEP (included in VTube-LASER) can now import Laservision PRT files:

|

NEW: IMPORT MULTIPLE SUPRAVISION FILES

NEW: IMPORT MULTIPLE SUPRAVISION FILES

|

VTube-STEP (included in VTube-LASER) can now import multiple Supravision files.

|

NEW: IMPORT MULTIPLE SOLID EDGE FILES INTO AN ASSEMBLY

NEW: IMPORT MULTIPLE SOLID EDGE FILES INTO AN ASSEMBLY

|

Import multiple SOLID EDGE files at one time into an ASSEMBLY.

|

ENHANCED: MORE USER INTERFACE SKINS TO CHOOSE FROM

ENHANCED: MORE USER INTERFACE SKINS TO CHOOSE FROM

|

There are now many more user interface skins to choose from in System Options. |

ENHANCED SOLID MODELING ENGINE

ENHANCED SOLID MODELING ENGINE

|

The solid modeling engine was updated. |

NEW: MADE CHANGES FOR FARO USB DRIVER VERSION 6

NEW: MADE CHANGES FOR FARO USB DRIVER VERSION 6

|

The version 6 driver for FARO would sometimes not reconnect after having left the scanner control window, so VTube now automatically disconnects and reconnects when you exit that window. |

NEW: "NO WAIT" FEATURE FOR SUPRAVISION NETWORK ALLOWS USB FLASH DRIVE COMMUNICATIONS

NEW: "NO WAIT" FEATURE FOR SUPRAVISION NETWORK ALLOWS USB FLASH DRIVE COMMUNICATIONS

|

The new SV No Wait feature allows you to communicate with benders using the Supravision Network protocol with USB flash drives. When VTube-LASER performs a RECALL, it no longer waits for an immediate answer. This means that it will never time-out in this mode. It assumes that the answer will come an undetermined future time.

|

OTHER CHANGES

OTHER CHANGES

- Build 98: The DCP (Diameter Cut Plane) now saves to project files and the default project file.

- Build 98: We reverted back to the correct scanning sound from the previous version. (This version accidentally included an experimental sound. Customers don't like it!)

- The PREVIOUS feature that steps back in the measurement step during measurement had some serious bugs. They are fixed. (NOTE: Do not use the "Previous" command in earlier versions.)

Other Pages

- See VTube-LASER Addata ZModem Communications Protocol for more information.

- Back to VTube-LASER

- Back to VTube Software Updates (for LASER Mode)

- See also VTube-STEP

- See also VTube-STEP Revisions

- See VTube-LASER Customer Support Page to download the latest version.

- See the tutorial on DCF - Dual Cylinder Fit

- See the tutorial on DCP - Diameter Cut Planes

- See VTube-LASER Cut Planes

- See How to Measure Tubes Attached to an Evaporator with the DCP Feature