|

VTube-LASER and VTube-STEP can communicate with bender controls using the Supravision Network protocol.

VTube-STEP can SEND data to benders using the protocol. VTube-LASER can SEND and RECALL data to/from benders for full corrections loops.

Follow this guide to setup the VTube for communications with benders using the Supravision Network protocol.

Benders that use Supravision Network for communications:

- AddisonMckee

- AIM Wirebender

- Benderlink for BLM

- COMCO DATALINX

- Crippa

- Eaton Leonard Lightspeed - See Eaton Leonard Lightspeed Communications Setup

- Horn Machine Tools with BendPro G1 or G2

- Benderlink for KEINS

- Benderlink for MiiC

- Pines Technology

- SMT Industries with CNC Bender ProControl

- Techno Industrial Machinery - with BendPro G1 or G2

- Eaton Leonard Tublip / Roboflex

- Unison Limited

- Benderlink for Chiyoda (older controls)

- SOCO (See VTube Communication for SOCO)

|

|

VTube Setup for Supravision Network Communications

In either VTube-STEP or VTube-LASER, press the System Options button:

Go to the Measure 2 tab menu and press on the Benderlink Setup button:

Follow these instructions:

|

VTube-STEP and VTube-LASER uses a Benderlink grid to set up the communications protocol for each bender. The grid is in Setup Options, Measure 2, Setup Benderlink Options menu.

In the Benderlink options menu, choose the bender to edit by selecting the cells in the bender row you want to set up.

- Set the bender name (this is for showing the bender name in the user interface only).

- Set the protocol by choosing Supravision Network. Note that many benders have their own dedicated Supravision Network protocol. If there is one available for your bender, then you can select that one rather than the generic Supravision Network protocol.

- Set the NetPath where files will be shared.

- Skip the ComPort setting because it has no application to this protocol.

- Set the timeout to from 5 to 10 seconds for most controls. This will give the control a few seconds to respond to requests.

- Set the Part Name Match to Yes or No. If the option is set to Yes, then a mismatched part name in the data will cause VTube-LASER to warn of a part name mismatch while receiving data.

- If the network location server has a fixed IP address, then the location can be pinged to prove that the network path is currently available before VTube attempts to save files in the network path.

- Set the number at the bender. This allows any bender in any row to have any bender number. Remember: If all Supravision Network-based benders share the same network path, then each bender should be assigned a unique bender number.

- If the bender uses CW rotations for positive rotations, then switch this feature ON. Stand at the front of the bender and jog the rotation positive. If the collet turns Clockwise, then this is the opposite direction used by VTube-LASER. Invert the rotation values by choosing YES in this cell.

- Exit this menu.

- Exit the System Options menu.

- Now VTube is setup for communications with this bender.

|

|

How to Use the VTube-LASER Supravision Network Communications

|

To communicate with a bender when using VTube-LASER, switch to the Bender Setup menu (see the navigation pane on the right), then follow these steps.

- If the bender control needs to be placed in communications mode, then do that now.

- Back at VTube-LASER, set the bender number on the top.

- If the Bender values in the blue columns are all zeros, or the data is not correct, then use the Setup this Window menu on the right to copy MASTER data into this menu. Also, you may need to copy MASTER part setup values into the top of the menu. If your bender requires it, you can also calculate a cut length.

- To SEND NEW data out to the bender, use the Setup the Bender button on the far right and press one of the Send buttons.

- To perform a CORRECTION to the bender, use the Bidirectional Communication menu on the right. Press the RECALL then the AUTO SEND to fully correct the bender.

|

|

How to SEND a New Part the Bender using VTube-STEP

|

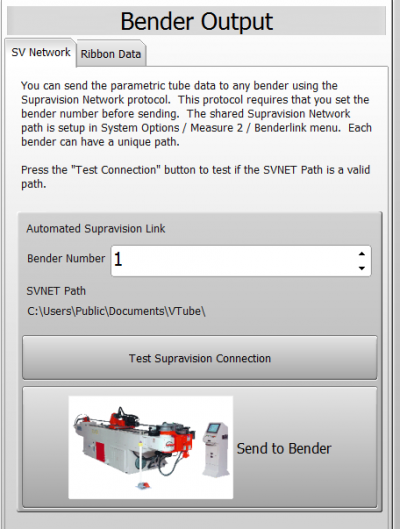

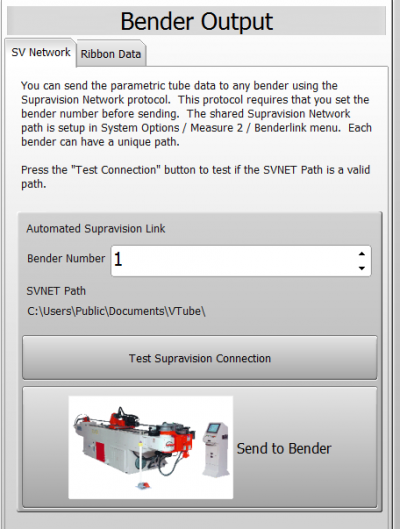

Use the VTube-STEP Bender Output menu to send new part data to a bender using Supravision Network protocol.

Go to the SV Network tab and choose the bender number. This will use the Benderlink setup in System Options to control the SVENT path.

- The Supravision Network protocol uses a bender number (from 1 to 99) to indicate which bender should pickup and use the Supravision file that is being saved by VTube-STEP to the file path in the network box.

- At the bender control, set the protocol to Supravision Network, set the bender number, set the path, and turn on communications if this is required.

|

|

Other Pages