Difference between revisions of "End-Scan Using the Scissor Motion"

From ATTWiki

(→Align the Scanner) |

(→Measure the Target) |

||

| Line 45: | Line 45: | ||

</table> | </table> | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

===Approve the Measurement On the Screen=== | ===Approve the Measurement On the Screen=== | ||

Revision as of 22:40, 27 January 2012

|

|

Why the End-Scan technique is important

|

This end-scan method is useful for ease-of-use and quickness.

|

How To Use This End-Scan Technique

|

Approve the Measurement On the Screen

|

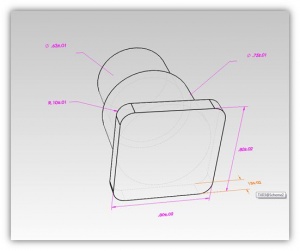

Using End Target Adapters

|

|

- Back to VTube-LASER