Difference between revisions of "End-Scan Using the End Wall"

From ATTWiki

(→About the End Wall Orientation) |

(→Avoiding Outliers) |

||

| Line 89: | Line 89: | ||

<tr valign=top> | <tr valign=top> | ||

<td width=300> | <td width=300> | ||

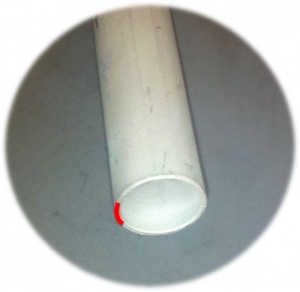

| − | When scanning the end walls of highly reflective tubing with striations like shown in the image on the right, it is better to either cover the end with a coat of Maganaflux | + | When scanning the end walls of highly reflective tubing with striations like shown in the image on the right, it is better to either cover the end with a coat of Maganaflux, Dynaflux, or foot powder spray, or cover it with an end target to avoid outlier points.<br><br> |

The image below an end target plastic label attached to the end of the same tube. In this case, there are no striations visible.<br><br> | The image below an end target plastic label attached to the end of the same tube. In this case, there are no striations visible.<br><br> | ||

[[image:EndWithEndWall_HighReflective_Striation_EndTarget.jpg|200px]] | [[image:EndWithEndWall_HighReflective_Striation_EndTarget.jpg|200px]] | ||

Revision as of 02:43, 29 September 2012

|

|

About the End Wall Orientation

|

We recommend this for increased precision where it is possible to strike the end wall. high-reflectivity and burrs are not an issue on the end wall of the tube. The End Wall method is also very useful for thicker wall tubes.

|

Measure Setup

|

How To Use This End-Scan Technique

The advantage of this method is that it is easy to use. The disadvantage is that it is more prone to outlier points from the inner diameter surface. |

Another Way to Use This End-Scan Technique

The advantage of this method is that it is less prone to outlier points. The disadvantage is that it is hard to aim at thinner walls. |

Avoiding Outliers

Other Pages

- See also End-Scan Using the Scissor Motion

- See also End-Scan Using End Targets

- Back to VTube-LASER