Difference between revisions of "End-Scan Using End Targets"

(→Measure the Target) |

|||

| (43 intermediate revisions by one user not shown) | |||

| Line 1: | Line 1: | ||

| − | <table> | + | <table cellpading=10> |

<tr cellpadding=10> | <tr cellpadding=10> | ||

<td width=300> | <td width=300> | ||

| − | [[image:vtube- | + | [[image:vtube-laser_logo_1.96.png|200px]]<br> |

How to perform super high accuracy end-scans using an end target.<br><br> | How to perform super high accuracy end-scans using an end target.<br><br> | ||

| − | * Back to [[VTube-LASER]] | + | |

| + | * Back to [https://www.advancedtubular.net/vtube-laser.html the Main VTube-LASER] web page | ||

| + | * Back to [[VTube-LASER]] Knowledgebase Page | ||

| + | * See [[End-Scan Technique Research]] | ||

</td> | </td> | ||

<td width=300> | <td width=300> | ||

| − | [[image:vtube- | + | [[image:vtube-laser_v2.7_screenshot.png|300px]] |

</td> | </td> | ||

</tr> | </tr> | ||

| Line 13: | Line 16: | ||

__NOTOC__ | __NOTOC__ | ||

| + | ===Why this End-Scan technique is important=== | ||

| − | === | + | <table cellpadding=10> |

| + | <tr valign=top> | ||

| + | <td width=500> | ||

The quick [[End-Scan Using the Scissor Motion]] technique is not always precisely repeatable if you use any of the AUTO exposure settings to set the LASER exposure in real-time. The reason is that as he laser drops off the end of the tube, the automatic exposure feature impacts which of the points are kept where the tube drops off (at the end). | The quick [[End-Scan Using the Scissor Motion]] technique is not always precisely repeatable if you use any of the AUTO exposure settings to set the LASER exposure in real-time. The reason is that as he laser drops off the end of the tube, the automatic exposure feature impacts which of the points are kept where the tube drops off (at the end). | ||

<br><br> | <br><br> | ||

| Line 20: | Line 26: | ||

<br><br> | <br><br> | ||

For tubes that don't qualify for either of the above techniques, we recommend end targets for ultra-precise measurements. | For tubes that don't qualify for either of the above techniques, we recommend end targets for ultra-precise measurements. | ||

| + | </td> | ||

| + | <td width=300> | ||

| + | </td> | ||

| + | </tr> | ||

| + | </table> | ||

| − | |||

| − | |||

| + | ===Highly-Reflective Ends with Concave Curved Burrs=== | ||

<table cellpadding=10> | <table cellpadding=10> | ||

<tr valign=top> | <tr valign=top> | ||

<td width=300> | <td width=300> | ||

| + | Shiney tube ends with burred edges that form CONCAVE curves facing the laser scanner camera can create an overload problem for the exposure. This can create flyers (points that are not on the surface) in any laser camera. | ||

<br><br> | <br><br> | ||

| − | * The image at the right shows the end of a copper tube with a | + | The example on the right shoes a burred end wall on the left side. For this kind of cut, it is critical that you apply a target like the green dot stickers shown here.<br><br> |

| − | *The solution is to use | + | Colors that work well are white, yellow, green. Avoid dark colors like black.<br><br> |

| + | [[image:green chromalabel dots.png|300px]]<br><br> | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:concave burred end walls.png|300px]]<br><br> | ||

| + | [[image:example of burred tube end.png|300px]]<br><br> | ||

| + | </td> | ||

| + | </tr> | ||

| + | </table> | ||

| + | |||

| + | ===Highly-Reflective End Walls that Have Chamferred or Jagged Edges=== | ||

| + | |||

| + | <table cellpadding=10> | ||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

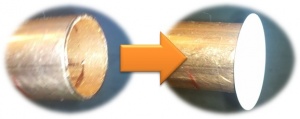

| + | * The image at the right shows the end of a copper tube with a jagged chamferred highly-reflective end-wall. It is very difficult to aim the laser at this end wall and ensure no flyers at the same time.<br><br> | ||

| + | *The solution is to use the targets on the end of the tubes. The example here shows white poly labels that measure at 0.004" thick and provide an excellent flat target for the laser.<br><br>(Note: Use the Plane-Point measurement in the built-in computer of the FARO Edge to confirm the thickness of the target.)<br><br> | ||

| + | * The offset from the target to the tube end is entered as a negative value in the Part Setup menu for either end. In this case, we use -0.004" offset.<br><br> | ||

*Any shape of target works well as long as it is LARGER than the diameter of the tube. Apply the target so that none of the end-wall can be scanned by the laser. | *Any shape of target works well as long as it is LARGER than the diameter of the tube. Apply the target so that none of the end-wall can be scanned by the laser. | ||

</td> | </td> | ||

<td width=300> | <td width=300> | ||

| − | [[image:EndWithTarget.jpg|300px]] | + | [[image:EndWithTarget.jpg|300px]]<br> |

| + | [[image:EndWithTarget2.jpg|300px]] | ||

</td> | </td> | ||

</tr> | </tr> | ||

</table> | </table> | ||

| + | ===VTube-LASER End Scan Measure Setup=== | ||

| + | <table cellpadding=10> | ||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | * In the Laser tab menu, we recommend that you use the standard setup of End Stripes per measure at from 10 to 20. | ||

| + | </td> | ||

| + | <td width=300> | ||

| + | [[image:vtl_v2.9.18_MeasureSetupLaserEndStripeCount.png|600px]]<br><br> | ||

| + | </td> | ||

| + | </tr> | ||

| + | |||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | * In the Separation Filter tab menu, we recommend that you set the End Scan Separation type to TIMER and set the TIMER to 0 milliseconds. | ||

| + | </td> | ||

| + | <td width=300> | ||

| + | [[image:vtl_v2.9.18_MeasureSetupSeparationFilterEndStripeSetup.png|600px]]<br><br> | ||

| + | </td> | ||

| + | </tr> | ||

| + | |||

| + | </table> | ||

===Measure the Target=== | ===Measure the Target=== | ||

| Line 47: | Line 97: | ||

<br><br> | <br><br> | ||

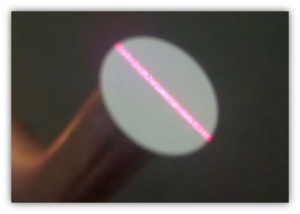

* Aim the laser at the target so that it strikes the target as perpendicular to the surface as possible. Avoid returning any points other than the target.<br><br> | * Aim the laser at the target so that it strikes the target as perpendicular to the surface as possible. Avoid returning any points other than the target.<br><br> | ||

| − | * | + | * Attempt to hold the laser motionless when collecting the stripes across the target to increase repeatability.<br><br> |

* Consistently place the line across the same area of the target from measure to measure. | * Consistently place the line across the same area of the target from measure to measure. | ||

</td> | </td> | ||

<td width=300> | <td width=300> | ||

| − | [[image:EndWithTargetAndLaser.jpg|300px]] | + | [[image:EndWithTargetAndLaser.jpg|300px]]<br> |

| + | [[image:EndWithTargetAndLaserCloseup.jpg|300px]]<br> | ||

</td> | </td> | ||

</tr> | </tr> | ||

</table> | </table> | ||

| − | |||

===Approve the Measurement On the Screen=== | ===Approve the Measurement On the Screen=== | ||

| − | |||

<table cellpadding=10> | <table cellpadding=10> | ||

<tr valign=top> | <tr valign=top> | ||

<td width=300> | <td width=300> | ||

| − | |||

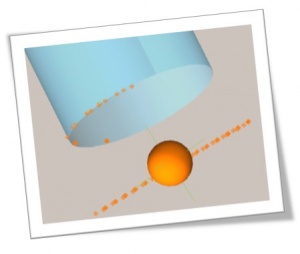

* The resulting geometry on the screen should appear like the image at he right.<br><br> | * The resulting geometry on the screen should appear like the image at he right.<br><br> | ||

* The end point generated on the screen should perfectly coincide with the stripes.<br><br> | * The end point generated on the screen should perfectly coincide with the stripes.<br><br> | ||

| Line 71: | Line 119: | ||

</tr> | </tr> | ||

</table> | </table> | ||

| + | |||

| + | ===Using End Target Adapters=== | ||

| + | |||

| + | <table cellpadding=10> | ||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | <br><br> | ||

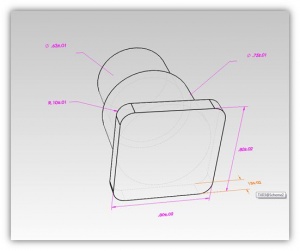

| + | * If you prefer using more durable end target adapter that plugs into the end of the tube, then they can be manufactured for repeatable measurements.<br><br> | ||

| + | * The end target surface should be painted or covered with a flat white or near-white target.<br><br> | ||

| + | * The offset from the target to the tube end is entered as a negative value in the Part Setup menu for either end. | ||

| + | </td> | ||

| + | <td width=300> | ||

| + | [[image:EndTargetPlugDesign.jpg|300px]] | ||

| + | </td> | ||

| + | </tr> | ||

| + | </table> | ||

| + | |||

| + | |||

| + | ===Other Pages=== | ||

| + | |||

| + | * See also [[End-Scan Using the Scissor Motion]] | ||

| + | * See also [[End-Scan Using the End Wall]] | ||

| + | * Back to [[VTube-LASER]] | ||

Latest revision as of 04:10, 16 February 2019

|

|

Why this End-Scan technique is important

|

The quick End-Scan Using the Scissor Motion technique is not always precisely repeatable if you use any of the AUTO exposure settings to set the LASER exposure in real-time. The reason is that as he laser drops off the end of the tube, the automatic exposure feature impacts which of the points are kept where the tube drops off (at the end).

|

Highly-Reflective Ends with Concave Curved Burrs

Highly-Reflective End Walls that Have Chamferred or Jagged Edges

|

VTube-LASER End Scan Measure Setup

|

|

|

Measure the Target

|

When it is time to perform and end-scan, use the following technique to scan the target:

|

Approve the Measurement On the Screen

|

Using End Target Adapters

|

|

Other Pages

- See also End-Scan Using the Scissor Motion

- See also End-Scan Using the End Wall

- Back to VTube-LASER