Difference between revisions of "CNC Bender v11-20090609"

| (32 intermediate revisions by one user not shown) | |||

| Line 2: | Line 2: | ||

[[image:Operatorstation_model.jpg|right]] | [[image:Operatorstation_model.jpg|right]] | ||

| − | + | __NOTOC__ | |

| + | ===[[image:Check.jpg|25px]] NEW - MORE Automatic Chuck Close Modes=== | ||

| + | There are more modes in automatic chuck close that allow you control when the automatic chuck close occurs. | ||

| + | <br><br> | ||

| + | [[image:cncbender_autochuckclose_mode.jpg|400px]]<br> | ||

===[[image:Check.jpg|25px]] NEW - Seam Detect Mode in PreBend Dynamic Options=== | ===[[image:Check.jpg|25px]] NEW - Seam Detect Mode in PreBend Dynamic Options=== | ||

| + | The '''seam detect logic''' was ported into the latest version of CNC Bender from the older LiteControl platform. This logic allows for seam detection logic modes including the capability of rotating the tube in the rotation spindle until the seam/scribe/etch is located.<br><br> | ||

| − | [[image:Seamdetect_application.jpg|300px]] | + | Please see [[CNC Bender Seam Detection]] for details. |

| − | [[image:Seamdetect_diagram.jpg| | + | <table> |

| + | <tr> | ||

| + | <td>[[image:Seamdetect_application.jpg|300px]]</td> | ||

| + | <td>[[image:Seamdetect_diagram.jpg|300px|right]]</td> | ||

| + | </tr> | ||

| + | </table> | ||

| − | |||

| − | + | <br> | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | ===[[image:Check.jpg|25px]] | + | ===[[image:Check.jpg|25px]] NEW - PreEnable Process List=== |

| + | The Pre Enable Proceslist allows for setting PID values BEFORE the axes are enabled. This allows the customer to quickly change the In Position Band value of any axis before the axis is enabled. | ||

| + | The first application of this is to allow for quick changing of the in position band of the bend axis from 1 degree In Position Band to 0.5 or 0.25 degrees. | ||

| + | <br> | ||

| + | <pre> | ||

| + | //==================================================== | ||

| + | //** PID Setup Section ** | ||

| + | // Choose only one of three | ||

| + | //==================================================== | ||

| − | + | //[display] PID Bend Axis - Set to 0.5 Degree Precision | |

| − | + | PID Bend Axis Full Degree Precision | |

| − | + | //PID Bend Axis Half Degree Precision | |

| − | + | //PID Bend Axis High Precision | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | [ | + | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

</pre> | </pre> | ||

| − | + | ===[[image:Check.jpg|25px]] NEW - Added Operators to the [IF] and [IFNOT] Blocks in the Process Lists=== | |

| − | + | When using the pos() command in an IF block of code, the following operators are now allowed: | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | == | + | # < |

| + | # > | ||

| + | # <= | ||

| + | # >= | ||

| + | # = | ||

| − | + | When using two character operators, it is important that there are no spaces between the two characters, or preceding the first character. Here is an example: | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

<pre> | <pre> | ||

| − | + | [IF] or, pos(1)<= 100 | |

| − | [ | + | DO This |

| − | + | [END] | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | [ | + | |

</pre> | </pre> | ||

| + | <br> | ||

| − | + | ===[[image:Check.jpg|25px]] NEW - Inputs that are TIMERS can now be a TYPE of "BEGIN"=== | |

| + | END-style timers pause after all outputs have been activated in a COMDEF. They cause the COMDEF to pause before the next step begins. The new BEGIN-style input timers pause BEFORE any outputs or servo commands are activated in the COMDEF. The timers are always set from the beginning of the COMDEF. | ||

| + | <br> | ||

| + | ===[[image:Check.jpg|25px]] REPAIRED - Manual Time Out Values Controlled By Low Level Hydraulic Value=== | ||

| − | + | The manual timeout values were always set to 6 seconds. Now they are set to whatever is programmed in the Low Level Compiler tab. | |

| + | <br><br> | ||

| − | |||

| − | |||

| − | <br><br> | + | ===[[image:Check.jpg|25px]] REPAIRED - Redesigned Processor Floating Message Window=== |

| + | [[image:cncbender_floating_processor_message_window2.jpg|400px]]<br><br> | ||

| + | The floating message window used to show processes in action has been resized to be less obtrusive to other screens.<br><br> | ||

| + | [[image:cncbender_floating_processor_message_window.jpg|400px]] | ||

=Other Pages= | =Other Pages= | ||

Latest revision as of 02:44, 13 June 2009

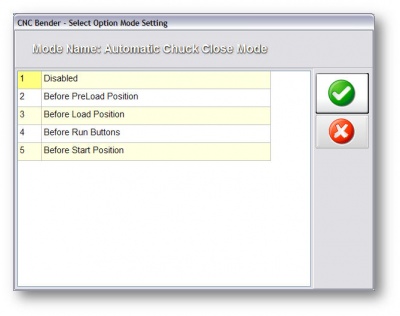

NEW - MORE Automatic Chuck Close Modes

NEW - MORE Automatic Chuck Close Modes

There are more modes in automatic chuck close that allow you control when the automatic chuck close occurs.

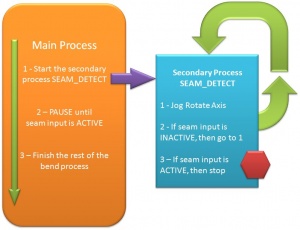

NEW - Seam Detect Mode in PreBend Dynamic Options

NEW - Seam Detect Mode in PreBend Dynamic Options

The seam detect logic was ported into the latest version of CNC Bender from the older LiteControl platform. This logic allows for seam detection logic modes including the capability of rotating the tube in the rotation spindle until the seam/scribe/etch is located.

Please see CNC Bender Seam Detection for details.

|

NEW - PreEnable Process List

NEW - PreEnable Process List

The Pre Enable Proceslist allows for setting PID values BEFORE the axes are enabled. This allows the customer to quickly change the In Position Band value of any axis before the axis is enabled.

The first application of this is to allow for quick changing of the in position band of the bend axis from 1 degree In Position Band to 0.5 or 0.25 degrees.

//==================================================== //** PID Setup Section ** // Choose only one of three //==================================================== //[display] PID Bend Axis - Set to 0.5 Degree Precision PID Bend Axis Full Degree Precision //PID Bend Axis Half Degree Precision //PID Bend Axis High Precision

NEW - Added Operators to the [IF] and [IFNOT] Blocks in the Process Lists

NEW - Added Operators to the [IF] and [IFNOT] Blocks in the Process Lists

When using the pos() command in an IF block of code, the following operators are now allowed:

- <

- >

- <=

- >=

- =

When using two character operators, it is important that there are no spaces between the two characters, or preceding the first character. Here is an example:

[IF] or, pos(1)<= 100 DO This [END]

NEW - Inputs that are TIMERS can now be a TYPE of "BEGIN"

NEW - Inputs that are TIMERS can now be a TYPE of "BEGIN"

END-style timers pause after all outputs have been activated in a COMDEF. They cause the COMDEF to pause before the next step begins. The new BEGIN-style input timers pause BEFORE any outputs or servo commands are activated in the COMDEF. The timers are always set from the beginning of the COMDEF.

REPAIRED - Manual Time Out Values Controlled By Low Level Hydraulic Value

REPAIRED - Manual Time Out Values Controlled By Low Level Hydraulic Value

The manual timeout values were always set to 6 seconds. Now they are set to whatever is programmed in the Low Level Compiler tab.

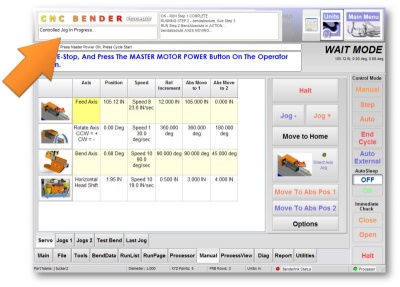

REPAIRED - Redesigned Processor Floating Message Window

REPAIRED - Redesigned Processor Floating Message Window

The floating message window used to show processes in action has been resized to be less obtrusive to other screens.

Other Pages

- Back to CNC Bender

- Back to CNC Bender Software Updates

- Read about Push Bending

- Read about Push Bend Profile Tables