Difference between revisions of "CNC Bender v10-20071120"

(→Menu: Machine Lube) |

(→Menu: Actions / Commands) |

||

| (68 intermediate revisions by one user not shown) | |||

| Line 12: | Line 12: | ||

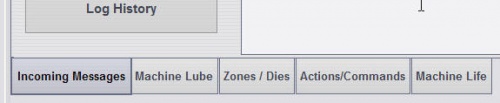

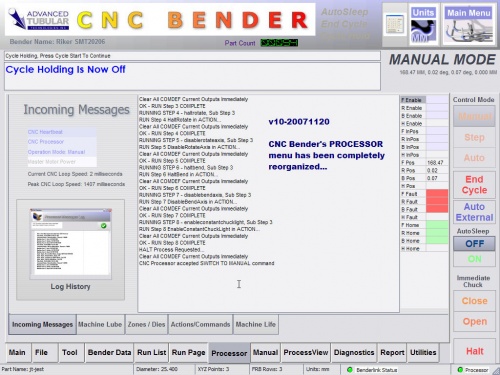

The CNC Processor menu is redesigned to include 5 new tab menus. | The CNC Processor menu is redesigned to include 5 new tab menus. | ||

| + | <br><br> | ||

| + | Read the details below. | ||

| + | |||

[[image:Cncprocessor_tabmenus.jpg|500px]] | [[image:Cncprocessor_tabmenus.jpg|500px]] | ||

| Line 18: | Line 21: | ||

<br><br> | <br><br> | ||

| + | |||

| + | ====Movie Reviewing Changes==== | ||

| + | View a movie of this revised menu [http://www.advancedtubular.com/cncbender/movies/cncbender_processormenu.html here] | ||

| + | |||

| + | [[image:Cncbender_cncprocessor_movie.jpg|300px|]]<br> | ||

====Menu: Incoming Messages==== | ====Menu: Incoming Messages==== | ||

| Line 23: | Line 31: | ||

<ul> | <ul> | ||

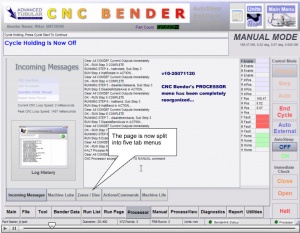

| − | The INCOMING MESSAGES menu now allows you to show an | + | The INCOMING MESSAGES menu now allows you to show an long-term history log:<br><br> |

[[image:Cncbender_cncprocessor_historylog.jpg|500px]] | [[image:Cncbender_cncprocessor_historylog.jpg|500px]] | ||

| Line 30: | Line 38: | ||

<br><br> | <br><br> | ||

| − | |||

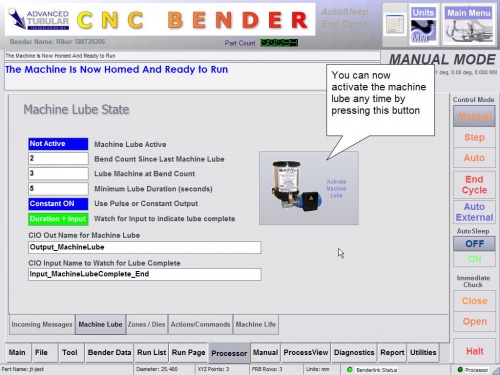

====Menu: Machine Lube==== | ====Menu: Machine Lube==== | ||

| Line 37: | Line 44: | ||

The new MACHINE LUBE tab has new controls and features:<br><br> | The new MACHINE LUBE tab has new controls and features:<br><br> | ||

[[image:Cncbender_cncprocessor_machinelube.jpg|500px]] | [[image:Cncbender_cncprocessor_machinelube.jpg|500px]] | ||

| − | <br> | + | <br><br> |

The machine lube setup is control from the CNCProcessor.cfg file in the c:\cnc\config folder. | The machine lube setup is control from the CNCProcessor.cfg file in the c:\cnc\config folder. | ||

| + | <br><br> | ||

<table cellpadding="15"> | <table cellpadding="15"> | ||

<tr> | <tr> | ||

| − | <td width=5></td> | + | <td width=150 bgcolor="#cccccc"> |

| + | <font size=5>New Features in Machine Lube</font></td> | ||

| + | <td width=300 bgcolor="#cceec2"><font size=5>Description</font></td> | ||

| + | </tr> | ||

| + | |||

| + | <tr> | ||

| + | |||

| + | <td bgcolor="#ccc5f5"> | ||

| + | <font size=3>Use Pulse or Constant Output</font></td> | ||

| + | |||

| + | <td bgcolor="#cceec2"> | ||

| + | |||

| + | This indicator shows how CNC Processor is set to handle the output point for the machine lube. The output can be toggled on and off (pulse) or switched on for the entire period of lube (constant). | ||

| + | <br><br> | ||

| + | This value is controlled in the Machine Lube section of the CNCProcessor.cfg file: | ||

| + | |||

| + | <b> | ||

| + | [Machine Lube]<br> | ||

| + | Pulse Machine Lube Pump= 0<br> | ||

| + | </b> | ||

| + | |||

| + | A value of 1 indicates PULSE. A value of 0 indicates CONSTANT. CONSTANT is the default setting. | ||

| + | |||

| + | </td> | ||

| − | |||

| − | |||

</tr> | </tr> | ||

<tr> | <tr> | ||

| − | |||

| − | <td | + | <td bgcolor="#ccc5f5"> |

| − | + | <font size=3>Watch for input to indicate lube complete</font></td> | |

| − | <td | + | <td bgcolor="#cceec2"> |

| − | + | ||

| − | </tr></table> | + | This indicator shows how CNC Processor is set to determine if the machine lube is completed. If an input is examined to determine if the machine lube is complete, then CNC Processor will activate the output for the duration entered in the setup, then begin examining the input indicated in the configuration. |

| + | <br><br> | ||

| + | This value is controlled in the Machine Lube section of the CNCProcessor.cfg file: | ||

| + | |||

| + | <b> | ||

| + | [Machine Lube]<br> | ||

| + | Watch For Machine Lube Complete Input= 1<br> | ||

| + | </b> | ||

| + | |||

| + | A value of 1 indicates watch for INPUT after the duration. A value of 0 indicates only run for the DURATION. | ||

| + | |||

| + | See below for how to set the input name. | ||

| + | |||

| + | </td> | ||

| + | |||

| + | </tr> | ||

| + | |||

| + | |||

| + | <tr> | ||

| + | <td bgcolor="#ccc5f5"> | ||

| + | <font size=3>CIO Input Name to Watch for Lube Complete</font></td> | ||

| + | <td bgcolor="#cceec2"> | ||

| + | The input name is set in the CIO section of CNCProcessor.cfg:<br> | ||

| + | <b> | ||

| + | [CIO]<br> | ||

| + | CIO Name of Input Machine Lube Complete=Input_MachineLubeComplete_End<br> | ||

| + | </b> | ||

| + | </td> | ||

| + | |||

| + | </tr> | ||

| + | |||

| + | |||

| + | |||

| + | |||

| + | </table> | ||

</ul> | </ul> | ||

| + | |||

| + | |||

| + | <br><br> | ||

| + | |||

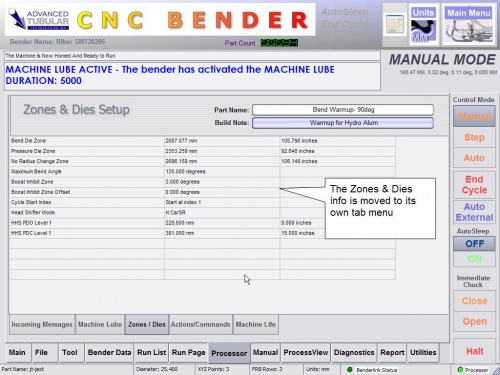

| + | ====Menu: Zones / Dies==== | ||

| + | |||

| + | <ul> | ||

| + | |||

| + | The ZONES / DIES menu shows the current Interference Zones and Die value setup that has been transferred to CNC Processor:<br><br> | ||

| + | |||

| + | [[image:Cncbender_cncprocessor_zonesdies.jpg|500px]] | ||

</ul> | </ul> | ||

| Line 66: | Line 138: | ||

<br><br> | <br><br> | ||

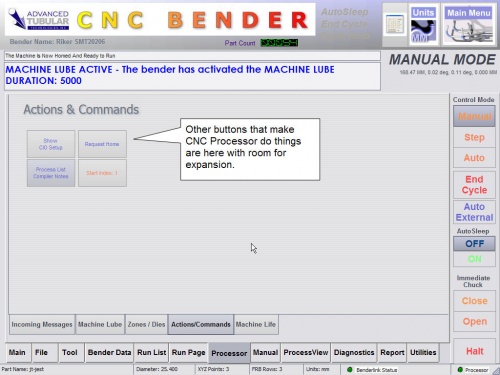

| − | === | + | ====Menu: Actions / Commands==== |

| − | + | <ul> | |

| + | |||

| + | The ACTIONS / COMMANDS menu now shows buttons that will allow for actions and commands to be sent to CNC Processor:<br><br> | ||

| + | |||

| + | [[image:Cncbender_cncprocessor_actionscommands.jpg|500px]] | ||

| + | <br><br> | ||

<table cellpadding="15"> | <table cellpadding="15"> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | <tr> | ||

| + | <td width=150 bgcolor="#cccccc"> | ||

| + | <font size=5>New Features in Actions / Commands</font></td> | ||

| + | <td width=300 bgcolor="#cceec2"><font size=5>Description</font></td> | ||

| + | </tr> | ||

| − | + | <tr> | |

| − | + | <td bgcolor="#ccc5f5"> | |

| + | [[image:Cncbender_cncprocessor_actionscommands_showciosetup.jpg]] | ||

| + | <font size=3>Show CIO Setup</font></td> | ||

| + | <td bgcolor="#cceec2"> | ||

| + | |||

| + | CNC Processor has knowledge of certain key CIO objects based on the setup in the CNCProcessor.cfg file. Each of these are listed in the [CIO] section of the configuration file. | ||

<br><br> | <br><br> | ||

| + | This new button sends a command to CNC Processor requesting a report of these CIO names and indexes. Use this to confirm that the CIO names are setup in CNCProcessor.cfg properly. | ||

| + | <br><br> | ||

| + | The report is displayed in the CNC Processor log. As soon as you press this button, a command is sent to CNC Processor requesting that it list the indexes and names, then CNC Bender switches you to the INCOMING MESSAGES tab menu to view the log. | ||

| + | <br><br> | ||

| + | Examine the values returned. All of the index values should be 0 (zero) or higher. If CNC Processor cannot find a CIO, then it will report a -1 for the index. If this is the case, then CNC Processor will be using a non-assigned input or output to determine states. <b>(See the below for an example log listing.)</b> | ||

| + | <br> | ||

| + | </td> | ||

| + | </tr> | ||

| + | </table> | ||

| − | == | + | <table> |

| + | <tr> | ||

| + | <td width = 400> | ||

| + | <font size=4>More About the Return Values Sent to the Log</font> | ||

| + | </td> | ||

| + | </tr> | ||

| − | + | <tr> | |

| + | <td width = 400> | ||

| + | CNC Processor has knowledge of 17 special CIO objects. (See the sample log report below.) The actual index values indicate the index of the input or output in the CIO library list (a list of all possible CIOs). Index numbers will vary depending on the actual setup of your CIO library. | ||

| + | </td> | ||

| + | </tr> | ||

| + | <tr> | ||

| + | <td> | ||

| + | <pre> | ||

| + | CIO Index: 11, CIO Name: Input_CycleHold_Button | ||

| + | CIO Index: 10, CIO Name: Input_CycleStart_Button | ||

| + | CIO Index: 15, CIO Name: Input_MachineHome_Button | ||

| + | CIO Index: 24, CIO Name: Input_LSRun_Button | ||

| + | CIO Index: 25, CIO Name: Input_RSRun_Button | ||

| + | CIO Index: 43, CIO Name: Input_ClampIsClosed_Begin | ||

| + | CIO Index: 188, CIO Name: Output_MachineLube | ||

| + | CIO Index: 397, CIO Name: Output_IBR_MachineLube_SignalON_Constant | ||

| + | CIO Index: 385, CIO Name: Output_IBR_RunProcess_OFF_Constant | ||

| + | CIO Index: 386, CIO Name: Output_IBR_RunProcess_ON_Constant | ||

| + | CIO Index: 394, CIO Name: Output_IBR_EndCycleSignal_Constant | ||

| + | CIO Index: 187, CIO Name: Output_MandrelLube_Repeat | ||

| + | CIO Index: 18, CIO Name: Input_MachineLubeComplete_End | ||

| + | CIO Index: 46, CIO Name: Input_MandrelForward_End | ||

| + | CIO Index: 217, CIO Name: Output_MandrelAdvance | ||

| + | CIO Index: 474, CIO Name: Output_MachineInFaultState_Enable | ||

| + | CIO Index: 489, CIO Name: Output_MachineInAutoMode_Enable | ||

| + | </pre> | ||

| + | </td> | ||

| + | </tr> | ||

| + | </table> | ||

| − | + | </ul> | |

<br><br> | <br><br> | ||

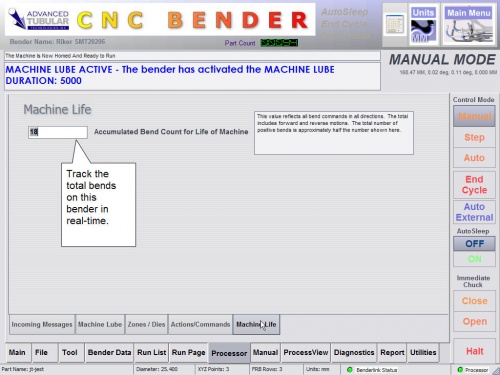

| − | === | + | ====Menu: Machine Life==== |

| − | + | <ul> | |

| + | The MACHINE LIFE menu shows the total number of bend arm motions currently on a bender. This includes all bend motion - both positive and negative moves:<br><br> | ||

| + | |||

| + | [[image:Cncbender_cncprocessor_machinelife.jpg|500px]] | ||

| + | |||

| + | </ul> | ||

| + | |||

| + | <br><br> | ||

| + | |||

| + | =CHANGES to CNC PROCESSOR= | ||

| + | |||

| + | ===[[image:Check.jpg|25px]] New Adjustable CPU Load Controls Using LOOP Section=== | ||

| + | |||

| + | The CNCProcessor.cfg file allows for two new programmable values that can have a significant effect on the CPU load when CNC Processor is idling. | ||

| + | <br><br> | ||

| + | The two new variables are placed in the <b>NEW</b> LOOP section like this: | ||

| + | |||

| + | <pre> | ||

| + | |||

| + | |||

| + | [Loop] | ||

| + | Power Off Manual Mode Pause= 500 | ||

| + | Power On Manual Mode Pause= 50 | ||

| + | |||

| + | </pre> | ||

| + | |||

| + | ====How It Works==== | ||

| + | <ul> | ||

<table cellpadding="15"> | <table cellpadding="15"> | ||

<tr> | <tr> | ||

<td></td> | <td></td> | ||

| − | <td | + | <td>Power OFF value is INCREASED</td> |

| − | <td | + | <td>The CNC Processor loop is paused every loop causing a DECREASED load on the CPU for other programs. The PAUSE time can be much LARGER when the power is OFF because outputs are not attempting to maintain the machine in a power ON state. <b>The end effect is that the CNC Bender user interface is faster.</b> |

| + | </td> | ||

</tr> | </tr> | ||

<tr> | <tr> | ||

<td></td> | <td></td> | ||

| − | <td | + | <td>Power ON value is INCREASED</td> |

| − | <td | + | <td> |

| + | For MANUAL mode with MASTER POWER ON, CNC Processor needs to handle the outputs and inputs, so the pause time for this state should be relatively low. <b>The end effect of using any positive value is that the CNC Bender user interface is faster.</b> | ||

| + | </td> | ||

</tr> | </tr> | ||

| + | </table> | ||

| + | |||

| + | </ul> | ||

| + | |||

| + | |||

| + | |||

| + | <table cellpadding="15"> | ||

<tr> | <tr> | ||

<td></td> | <td></td> | ||

| − | <td bgcolor="# | + | <td width=200 bgcolor="#b0c8fa"><b>CPU Speed/OS</b></td> |

| − | <td bgcolor="# | + | <td width=200 bgcolor="#fae8b0"><b>Suggestions</b></td> |

</tr> | </tr> | ||

| − | </ | + | <tr> |

| + | <td></td> | ||

| + | <td bgcolor="#d3e0f7">Faster CPUs<br><b>Win 2000</b></td> | ||

| + | <td bgcolor="#f7ebc3"><b>Power Off = 50<br>Power On = 50</b> | ||

| + | <br> | ||

| + | Faster computers running Windows 2000 can use with these values set to 0 milliseconds without slowing CNC Bender.<br> | ||

| + | </td> | ||

| + | </tr> | ||

| + | <tr> | ||

| + | <td></td> | ||

| + | <td bgcolor="#d3e0f7">Slower CPUs<br><b>Win 2000</b></td> | ||

| + | <td bgcolor="#f7ebc3"><b>Power Off = 250<br>Power On = 50</b> | ||

| + | <br> | ||

| + | For slow Win2000 computers, the POWER OFF value is important to speed up the CNC Bender user interface. | ||

| + | </td> | ||

| + | </tr> | ||

| − | |||

| − | = | + | <tr> |

| + | <td></td> | ||

| + | <td bgcolor="#d3e0f7">Fast CPU<br><b>Win XP</b></td> | ||

| + | <td bgcolor="#f7ebc3"><b>Power Off = 500<br>Power On = 50</b> | ||

| + | <br> | ||

| + | Faster computers running Windows XP need these values set to at least 500 and 50. The CPU load in Win XP with these values set to 0 is high to cause a significant drag in the operating system.<br> | ||

| + | </td> | ||

| + | </tr> | ||

| − | === | + | <tr> |

| + | <td></td> | ||

| + | <td bgcolor="#d3e0f7">Slow CPU<br><b>Win XP</b></td> | ||

| + | <td bgcolor="#f7ebc3"><b>Power Off = 250<br>Power On = 50</b> | ||

| + | <br> | ||

| + | Slower computers running Windows XP need these values set lower or CNC Processor may never finish loading at startup.<br> | ||

| + | </td> | ||

| + | </tr> | ||

| − | + | </table> | |

| + | <br><br> | ||

| + | ===[[image:Check.jpg|25px]] Changed Section Name in Configuration=== | ||

| + | |||

| + | The CNCProcessor.cfg file section [Intervals] has been changed to [Machine Lube]. | ||

<br><br> | <br><br> | ||

| − | < | + | These are the available values in the Machine Lube section: |

| + | <pre> | ||

| + | [Machine Lube] | ||

| + | Machine Lube Duration= 5000 | ||

| + | Lube Machine At Bend Count= 1000 | ||

| + | Pulse Machine Lube Pump= 0 | ||

| + | Watch For Machine Lube Complete Input= 1 | ||

| + | </pre> | ||

| + | |||

| + | The old name in older CNCProcessor.cfg files is [Intervals]. | ||

| + | |||

<br><br> | <br><br> | ||

| + | |||

| + | <table cellpadding="35"> | ||

| + | <tr><td width=50></td> | ||

| + | <td width=300 bgcolor="#f0f0f0"> | ||

| + | <font size=5>[[image:Gear_warning.jpg]] <b>SETUP NOTE</b><br><br></font> | ||

| + | <font size=3>This configuration file change affects setups from older versions<br><br> | ||

| + | Copying older CNCProcessor.cfg file to a new configuration requires that you hand adjust the setup by changing SECTION names (like [Intervals] to [Machine Lube]).<br> | ||

| + | <br> | ||

| + | When making thee manual changes, be absolutely sure that you are using correctly named variable names and section names - or the value you believe you have setup will not take effect.</font></td></tr></table> | ||

=How to UPGRADE= | =How to UPGRADE= | ||

[[image:Cncbender.jpg|100px|thumb|CNC Bender User Interface for ProControl]] | [[image:Cncbender.jpg|100px|thumb|CNC Bender User Interface for ProControl]] | ||

| − | If your operator station contains one of the versions listed below, then they can be upgraded | + | If your operator station contains one of the versions listed below, then they can be upgraded: |

| + | <br> | ||

| + | *[[CNC Bender v10-20071030]] | ||

*[[CNC Bender v10-20071003]] | *[[CNC Bender v10-20071003]] | ||

*[[CNC Bender v10-20070928]] | *[[CNC Bender v10-20070928]] | ||

| Line 144: | Line 358: | ||

*[[CNC Bender v10-20070828]] | *[[CNC Bender v10-20070828]] | ||

*[[CNC Bender v10-20070914]] | *[[CNC Bender v10-20070914]] | ||

| − | |||

<br><br> | <br><br> | ||

| − | |||

See our [[CNC Bender Upgrade Policy]] page for details regarding the charges for the upgrade software.<br> | See our [[CNC Bender Upgrade Policy]] page for details regarding the charges for the upgrade software.<br> | ||

| − | [[image:Nav_down_green.png]][http://www.advancedtubular.com/cncbender/setup_cncbender_v10- | + | [[image:Nav_down_green.png]][http://www.advancedtubular.com/cncbender/setup_cncbender_v10-20071120.exe| Download the setup file by clicking on this link.]<br> |

''This setup file requires a password to run. | ''This setup file requires a password to run. | ||

Please contact [[John Esralian]] for upgrade prices and password information.'' | Please contact [[John Esralian]] for upgrade prices and password information.'' | ||

Latest revision as of 16:37, 24 November 2007

Contents |

CHANGES to CNC BENDER

Redesigned Processor Menu

Redesigned Processor Menu

The CNC Processor menu is redesigned to include 5 new tab menus.

Read the details below.

Movie Reviewing Changes

View a movie of this revised menu here

Menu: Incoming Messages

Menu: Machine Lube

-

The new MACHINE LUBE tab has new controls and features:

The machine lube setup is control from the CNCProcessor.cfg file in the c:\cnc\config folder.

| New Features in Machine Lube | Description |

| Use Pulse or Constant Output |

This indicator shows how CNC Processor is set to handle the output point for the machine lube. The output can be toggled on and off (pulse) or switched on for the entire period of lube (constant).

[Machine Lube] A value of 1 indicates PULSE. A value of 0 indicates CONSTANT. CONSTANT is the default setting. |

| Watch for input to indicate lube complete |

This indicator shows how CNC Processor is set to determine if the machine lube is completed. If an input is examined to determine if the machine lube is complete, then CNC Processor will activate the output for the duration entered in the setup, then begin examining the input indicated in the configuration.

[Machine Lube] A value of 1 indicates watch for INPUT after the duration. A value of 0 indicates only run for the DURATION. See below for how to set the input name. |

| CIO Input Name to Watch for Lube Complete |

The input name is set in the CIO section of CNCProcessor.cfg: |

Menu: Zones / Dies

-

The ZONES / DIES menu shows the current Interference Zones and Die value setup that has been transferred to CNC Processor:

Menu: Actions / Commands

-

The ACTIONS / COMMANDS menu now shows buttons that will allow for actions and commands to be sent to CNC Processor:

| New Features in Actions / Commands | Description |

| Show CIO Setup |

CNC Processor has knowledge of certain key CIO objects based on the setup in the CNCProcessor.cfg file. Each of these are listed in the [CIO] section of the configuration file.

|

|

More About the Return Values Sent to the Log |

|

CNC Processor has knowledge of 17 special CIO objects. (See the sample log report below.) The actual index values indicate the index of the input or output in the CIO library list (a list of all possible CIOs). Index numbers will vary depending on the actual setup of your CIO library. |

CIO Index: 11, CIO Name: Input_CycleHold_Button CIO Index: 10, CIO Name: Input_CycleStart_Button CIO Index: 15, CIO Name: Input_MachineHome_Button CIO Index: 24, CIO Name: Input_LSRun_Button CIO Index: 25, CIO Name: Input_RSRun_Button CIO Index: 43, CIO Name: Input_ClampIsClosed_Begin CIO Index: 188, CIO Name: Output_MachineLube CIO Index: 397, CIO Name: Output_IBR_MachineLube_SignalON_Constant CIO Index: 385, CIO Name: Output_IBR_RunProcess_OFF_Constant CIO Index: 386, CIO Name: Output_IBR_RunProcess_ON_Constant CIO Index: 394, CIO Name: Output_IBR_EndCycleSignal_Constant CIO Index: 187, CIO Name: Output_MandrelLube_Repeat CIO Index: 18, CIO Name: Input_MachineLubeComplete_End CIO Index: 46, CIO Name: Input_MandrelForward_End CIO Index: 217, CIO Name: Output_MandrelAdvance CIO Index: 474, CIO Name: Output_MachineInFaultState_Enable CIO Index: 489, CIO Name: Output_MachineInAutoMode_Enable |

Menu: Machine Life

-

The MACHINE LIFE menu shows the total number of bend arm motions currently on a bender. This includes all bend motion - both positive and negative moves:

CHANGES to CNC PROCESSOR

New Adjustable CPU Load Controls Using LOOP Section

New Adjustable CPU Load Controls Using LOOP Section

The CNCProcessor.cfg file allows for two new programmable values that can have a significant effect on the CPU load when CNC Processor is idling.

The two new variables are placed in the NEW LOOP section like this:

[Loop] Power Off Manual Mode Pause= 500 Power On Manual Mode Pause= 50

How It Works

| Power OFF value is INCREASED | The CNC Processor loop is paused every loop causing a DECREASED load on the CPU for other programs. The PAUSE time can be much LARGER when the power is OFF because outputs are not attempting to maintain the machine in a power ON state. The end effect is that the CNC Bender user interface is faster. | |

| Power ON value is INCREASED |

For MANUAL mode with MASTER POWER ON, CNC Processor needs to handle the outputs and inputs, so the pause time for this state should be relatively low. The end effect of using any positive value is that the CNC Bender user interface is faster. |

| CPU Speed/OS | Suggestions | |

| Faster CPUs Win 2000 |

Power Off = 50 Power On = 50

|

|

| Slower CPUs Win 2000 |

Power Off = 250 Power On = 50

|

|

| Fast CPU Win XP |

Power Off = 500 Power On = 50

|

|

| Slow CPU Win XP |

Power Off = 250 Power On = 50

|

Changed Section Name in Configuration

Changed Section Name in Configuration

The CNCProcessor.cfg file section [Intervals] has been changed to [Machine Lube].

These are the available values in the Machine Lube section:

[Machine Lube] Machine Lube Duration= 5000 Lube Machine At Bend Count= 1000 Pulse Machine Lube Pump= 0 Watch For Machine Lube Complete Input= 1

The old name in older CNCProcessor.cfg files is [Intervals].

How to UPGRADE

If your operator station contains one of the versions listed below, then they can be upgraded:

- CNC Bender v10-20071030

- CNC Bender v10-20071003

- CNC Bender v10-20070928

- CNC Bender v10-20070920

- CNC Bender v10-20070726b

- CNC Bender v10-20070803

- CNC Bender v10-20070828

- CNC Bender v10-20070914

See our CNC Bender Upgrade Policy page for details regarding the charges for the upgrade software.

![]() Download the setup file by clicking on this link.

Download the setup file by clicking on this link.

This setup file requires a password to run.

Please contact John Esralian for upgrade prices and password information.

For instructions on how to install the file see: How to Install a CNC Bender Upgrade