CNC Bender v10-20071030

Contents |

CHANGES to CNC BENDER

Conditional Carriage Cross Slide RETRACT - Only if DIES ARE RETRACTED

Conditional Carriage Cross Slide RETRACT - Only if DIES ARE RETRACTED

If the clamp is closed, then carriage sliding AWAY from the dies is overridden.

The original command was inserted like this:

AllCrossSlidesAdvance = cto:6000

The new logic checks for both clamp and pressure die open before it will allow for the carriage to cross slide. If either of these dies is not fully retracted, the AllCrossSlideHome is skipped:

[IF] AND, input=Input_ClampIsHome_Begin, input=Input_PressureDieIsHome_Begin [DISPLAY] Next Step: (Center Carriage) Home All Cross Slides AllCrossSlidesHome = cto:6000 [DISPLAY] Completed: (Center Carriage) Home All Cross Slides [END]

This new logic allows for option combinations that were not possible before. For example, RECAPTURE and FEED AWAY FROM DIES can now be enabled together.

Changed a Range Error Message for Clarity

Changed a Range Error Message for Clarity

A range error message was changed by adding the RADIUS CHANGE information to help users find a solution this problem:

|

Immediate Message |

Production Cycle Time Value

Production Cycle Time Value

The "Complete Cycle Time" is changed to "Production Cycle Time" and now provides the overall time from part to part.

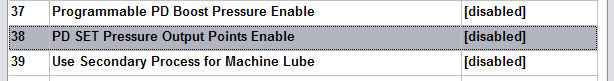

New General Dynamic Option - PD Set Pressure

New General Dynamic Option - PD Set Pressure

If this option is enabled, then the PD Set Pressure Output Points are enabled using the new SetPDPressureOutputPoints command.

Changed Terminology

Changed Terminology

The following terms are changed in CNC Bender user interface:

| ORIGINAL | NEW | |

| In Low Level Tangent to Collet Face |

In Low Level Machine Length |

|

| In Run Page Complete Cycle Time |

In Run Page Production Cycle Time |

CHANGES to CNC PROCESSOR

Optimized for Win2000 or WinXP

Optimized for Win2000 or WinXP

This CNC Processor recognizes the current operating system and optimizes the loop for each operating system.

How to UPGRADE

If your operator station contains one of the versions listed below, then they can be upgraded through simple self-installation:

- CNC Bender v10-20071003

- CNC Bender v10-20070928

- CNC Bender v10-20070920

- CNC Bender v10-20070726b

- CNC Bender v10-20070803

- CNC Bender v10-20070828

- CNC Bender v10-20070914

See our CNC Bender Upgrade Policy page for details regarding the charges for the upgrade software.

![]() Download the setup file by clicking on this link.

Download the setup file by clicking on this link.

This setup file requires a password to run.

Please contact John Esralian for upgrade prices and password information.

For instructions on how to install the file see: How to Install a CNC Bender Upgrade