Difference between revisions of "Benderlink for SolidWorks"

(→Other References) |

(→Features) |

||

| Line 15: | Line 15: | ||

<li> - Convert the tube data to bender data</li> | <li> - Convert the tube data to bender data</li> | ||

<li> - Save / Recall the bender data</li> | <li> - Save / Recall the bender data</li> | ||

| − | <li> - Program and | + | <li> - Program and calculate cut-length to remove elongation using the [[Bend Reduction Editor]]</li> |

<li> - Send new nominal data to benders that support [[SVNET]] protocol.</li> | <li> - Send new nominal data to benders that support [[SVNET]] protocol.</li> | ||

<li> - With a measuring center: Make and send correction data to benders that support the [[SVNET]] protocol.</li> | <li> - With a measuring center: Make and send correction data to benders that support the [[SVNET]] protocol.</li> | ||

Revision as of 13:46, 7 March 2008

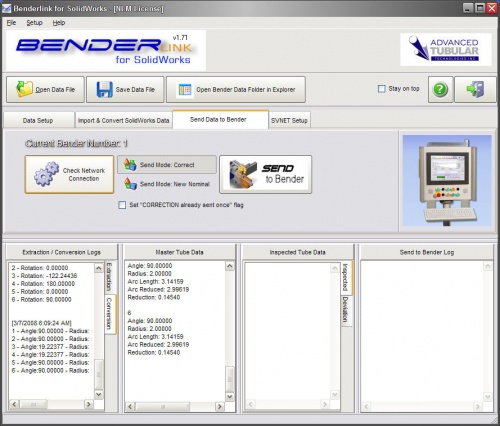

Benderlink for SolidWorks software is designed to convert from SolidWorks to bender data then to connect SolidWorks workstations to SVNET-based benders.

If a measuring center arm is setup to sketch a 3D centerline of a measured tube shape, then Benderlink will help you reverse-engineer tube shapes, and assist in correcting the bender's data.

Contents |

Features

The main features of this software:

- - Read tube data from SolidWorks

- - Convert the tube data to bender data

- - Save / Recall the bender data

- - Program and calculate cut-length to remove elongation using the Bend Reduction Editor

- - Send new nominal data to benders that support SVNET protocol.

- - With a measuring center: Make and send correction data to benders that support the SVNET protocol.

- - With a measuring center: Reverse-engineer tube shapes

The reverse-engineering feature is performed by using 3D sketch with a measuring center - like a FARO arm. The tube centerline is sketched in 3D, then transferred to Benderlink for SolidWorks.

The correction feature is performed by measuring a tube with FARO arm, using this data to create a tube centerline in SolidWorks, then allow Benderlink to compare this inspected data with the MASTER data.

Software Updates

| March 7, 2008 | Benderlink for SolidWorks 1.71 |

Demonstration Videos for Benderlink for SolidWorks

Download and view videos that show how Benderlink for SolidWorks works.

- [1]Introductory Demonstration Video

- [2]Sending Data to the Bender

- [3]Bender Corrections Loops

- [4]Special case extraction: Contiguous Arcs with no straight segments (typical of push-roll bending)

SolidWorks Compatibility

Benderlink for SolidWorks has been tested and verified with these versions of SolidWorks:

Other References

- View update information for this software: Benderlink for SolidWorks Version Updates Page

- For details on NLM installation, see: Benderlink for SolidWorks NLM Installation

- The Bend Reduction Editor page describes how to use the editor