|

BendPro is a popular bender software package used by multiple bender OEMs in the industry. There are two versions commonly used: G1 and G2

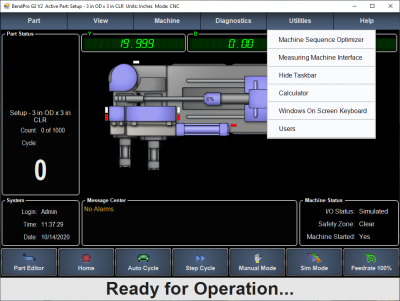

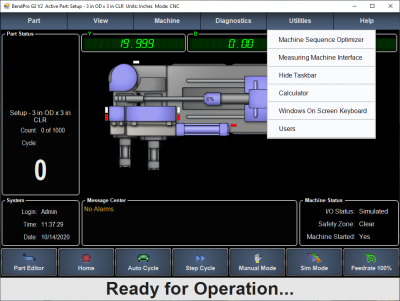

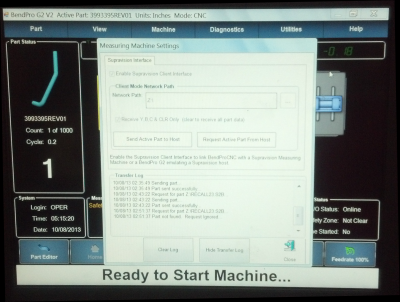

This is a BendPro G2 control on a Horn bender.

|

|

About BendPro Measuring Center Communications

BendPro uses Supravision Network communications as a standard for communications. Communications are straight-forward, efficient, and very fast.

The BendPro can be setup to communicate with:

How to Check if Communications is Possible

G2 Version

|

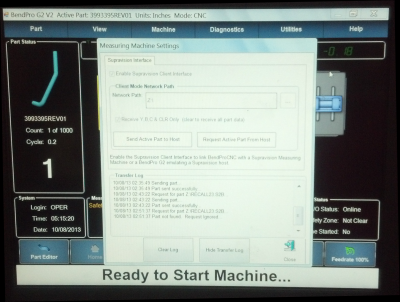

The Supravision link is sold by Current Tech as an option. It's important to verify that this option is switched on when discovering if a BendPro G2 is ready for communication. Click on the Utilities pulldown menu, then click on the Measuring Machine Interface option.

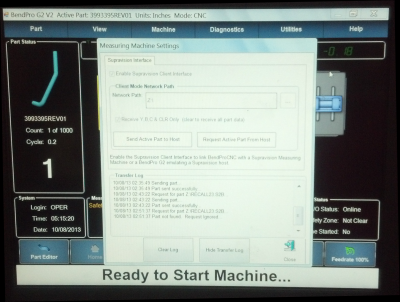

If you see the Measuring Machine Settings menu will allow you to enable the Supravision Client Interface, then your bender has communication capability.

|

|

G1 Version

|

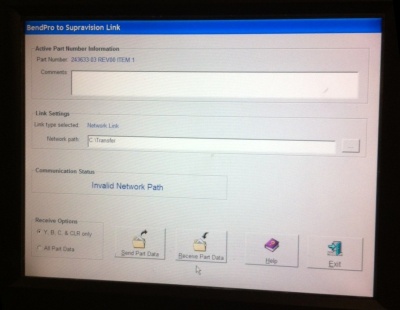

Verify that this option is switched on when discovering if a BendPro G1 is ready for communication.

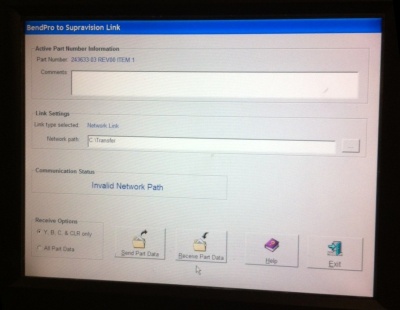

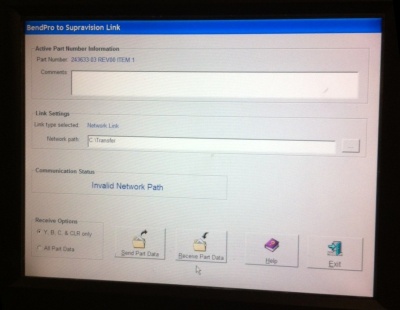

If you see the BendPro to Supravision Link window then your software has communication capability.

|

Click on Edit Part button in the main screen:

|

Communications Notes for the G2

G2 Version Communications Setup

- Enter the Utilities / Measuring Machine Settings menu.

- Put a check in the checkbox to enable communications.

- Setup the path that Supravision Network will use for communications.

- Use the Machine Parameters / General Options to setup the correct bender number.

- The G2 user interface does not need to be in the Measuring Center menu to communicate. However, that menu includes a log that displays the time of the last data transmission. If there are errors, then this is where they will be listed. So it is beneficial to change to that menu before communications.

|

|

G2 Version Communications Rules

|

The following rules apply for communication using the Supravision Network protocol:

- To correct an existing part in the bender, the part must be saved in the BendPro database, and must be the active part.

- The part number must have no spaces. The G2 controls will parse the part number so that all letters after the first space are deleted. For example: "01234 REV0" will be trimmed to "01234". If this new part number does not exist, then the G2 control will ask if you want to import a new part.

- Changing the first straight length will also change the START position for the first bend.

If you are using VTube-LASER to correct the bender, and don't want the first or the last straight lengths to change, then manually set the first adjustment to zero in the Bender Setup menu before sending a correction.

|

|

Communications Notes for the G1

G1 Version Communications Setup

- Press Edit Part.

- Press the Measuring Machine button to enter the Supravision Network screen (see the image on the right).

- Setup the path that Supravision Network will use for communications.

- Use the Machine Parameters / General Options to setup the correct bender number.

|

|

G1 Version Communications Rules

|

The following rules apply for communication using the Supravision Network protocol:

- Unlike the G2 user interface, the G1 user interface needs to be displaying the Supravison menu during communications. The menu includes a single line that displays if communications works.

- Spaces are allowed in the part number - but NOT recommended. If the exact number of spaces don't match, then the communication will fail. It is difficult to differentiate between one space and two spaces, and the G1 can have spaces AFTER the part name - which is not discernable until you enter the keyboard to edit the name. Recommendation: Replace the spaces with underscores.

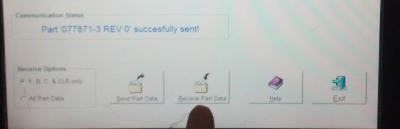

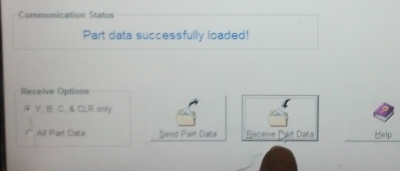

- During a send from the measuring center to the bender it is necessary for the operator to walk out to the bender and press the RECEIVE PART DATA button.

For VTube-LASER, there is no timeout. For Supravision or DOCS, if the timeout occurs before the operator arrives at the bender to press the button, then DOCS and Supravision will delete the data file - and the communications will fail.

If there are errors, then this is where they will be listed.

- To correct an existing part in the bender, the part must be saved in the BendPro database, and must be the active part.

- Unlike the G2, the G1 can have spaces in the part number.

- Changing the first straight length will also change the START position for the first bend.

If you are using VTube-LASER to correct the bender, and don't want the first or the last straight lengths to change, then manually set the first adjustment to zero in the Bender Setup menu before sending a correction.

|

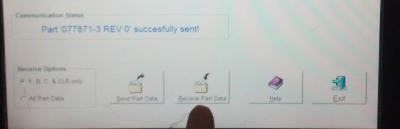

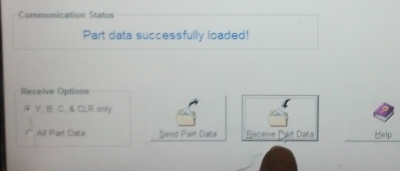

This image shows the message after the part has been received:

This image shows the message after the part has been received:

|

General Communications Notes

Part Note Length Limitation

|

BendPro operators can easily type in a part note that is very long:

- Supravsion will shutdown without warning if it receives a part note with more than 95 characters.

- VTube-LASER can handle any part note length.

|

|

Speed and Centerline Radius Fields Observed

- BendPro returns the YBC axis SPEEDS in the Supravision data transfer. This data should be observed and returned from any Benderlink system - or the speeds may be reset to a new value during the next correction.

- BendPro will use the incoming Ceterline Radius values in the Supravision transmission (rather than the values in the tool page). This data should be observed and returned from any Benderlink system - or the radii may be reset to the new incoming vale during the next correction.

|

|

Non-Bending YBC Row Avoidance Moves

|

BendPro operators will sometimes use non-bending rows in the YBC data to enable special avoidance moves.

- Supravision and DOCs cannot handle data with avoidance moves inserted in the YBC data. It is necessary to make manual corrections in these cases.

- VTube-LASER uses a data mapping feature to allow for any number of non-bending rows.

|

|

Handling Inverted Rotations

- DOCs software will sometimes invert rotations (to move in the opposite direction) - especially when making rotation corrections around the 180 degree area. Be aware of this and be prepared to reset any rotation that is moving in the wrong direction.

- Supravision observes and maintains the rotation direction found at the bender.

- VTube-LASER allows operators to check an Invert checkbox to invert any rotation corrected to the opposite direction. Operators of VTube should observe any rotation that is close to 180 degrees to check for the possibility for the need for inversion. This gives operators complete control over the rotation direction during correction.

|

|

Other