CNC Bender v12-20120723

From ATTWiki

v12-20120723

|

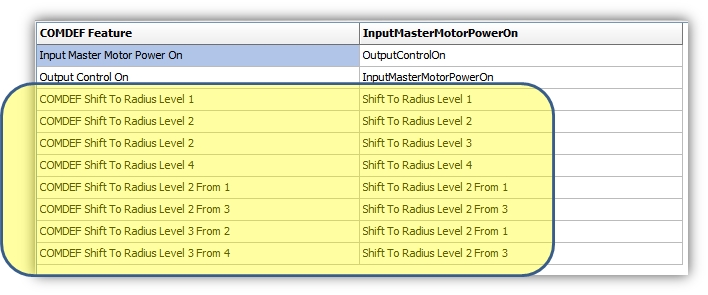

Radius Level Shift Command Names Simplified

Radius Level Shift Command Names Simplified

|

Radius Level Shift Command Names Can Be Changed

Radius Level Shift Command Names Can Be Changed

|

Changed the Name of "Low Level Options List" to "Setup Options List"

Changed the Name of "Low Level Options List" to "Setup Options List"

|

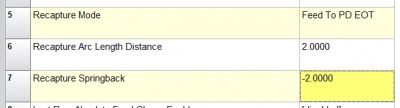

FIX: Recapture Feed Into PD Collision Message

FIX: Recapture Feed Into PD Collision Message

|

Previous versions of CNC Bender would show a FEED into PD collision error in recapture mode when the PDA is motion controlled even if the Pressure Die was already home. The problem would occur when the PDA arrived home before the PD arrives home, signalling CNC Processor to move to the next step too early. In motion-controlled COMDEFs, the arrival of a servo axis to position overrides any waiting for proximity switches to go active. So the PD would still be moving back when the Feed axis was told to start moving. The fix was to separate the PD return from the PDA return COMDEFs, and make the PD return occur first. This ensures that the PD moves all the way home before the PDA motion moves home. |

Other Pages

- Back to CNC Bender

- Back to CNC Bender Software Updates

- See CNC Bender General Information

- See Teach Mode

- See Custom Commands