CNC Bender v11-20090826

ENHANCED - END CYCLE MODE - Can Be Controlled By External Processes

ENHANCED - END CYCLE MODE - Can Be Controlled By External Processes

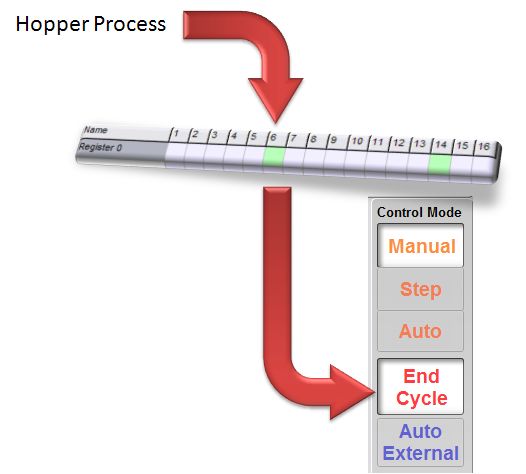

Previous versions of CNC Bender controlled the End Cycle Mode from within the CNC Bender interface only in the control mode bar (on the right side of the screen). Now CNC Bender monitors a programmable CIO input (in Low Level) that can also change the End Cycle mode from a processlist or an external computer. The process simply changes the point state being monitored, and the mode button in the main CNC Bender screen set itself to the state automatically.

|

In this example the Hopper secondary process detected a problem and set point 6 to "active" in that register. This is how the feature was setup:

|

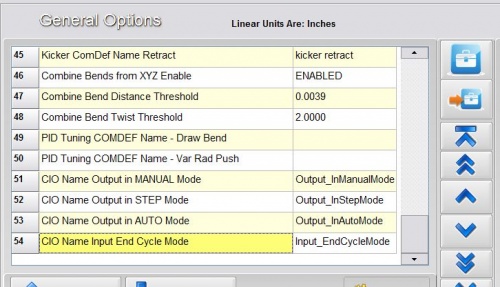

NEW - END CYCLE Mode INPUT CIO Name in Low Level Options

NEW - END CYCLE Mode INPUT CIO Name in Low Level Options

|

The input CIO Name for End Cycle is now programmable in Low Level Options list. |

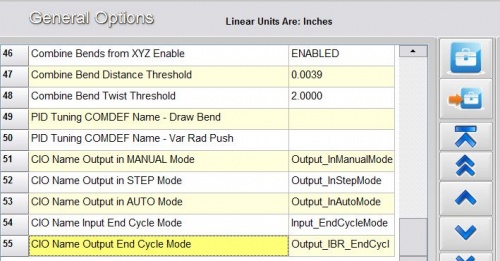

NEW - END CYCLE Mode OUTPUT CIO Name in Low Level Options

NEW - END CYCLE Mode OUTPUT CIO Name in Low Level Options

| The output CIO Name for End Cycle is now programmable in Low Level Options list. This name is used to teach CNC Processor (controls the bender) how to change the state of the End Cycle mode. |

Other Pages

- Back to CNC Bender

- Back to CNC Bender Software Updates

- See End Cycle Mode