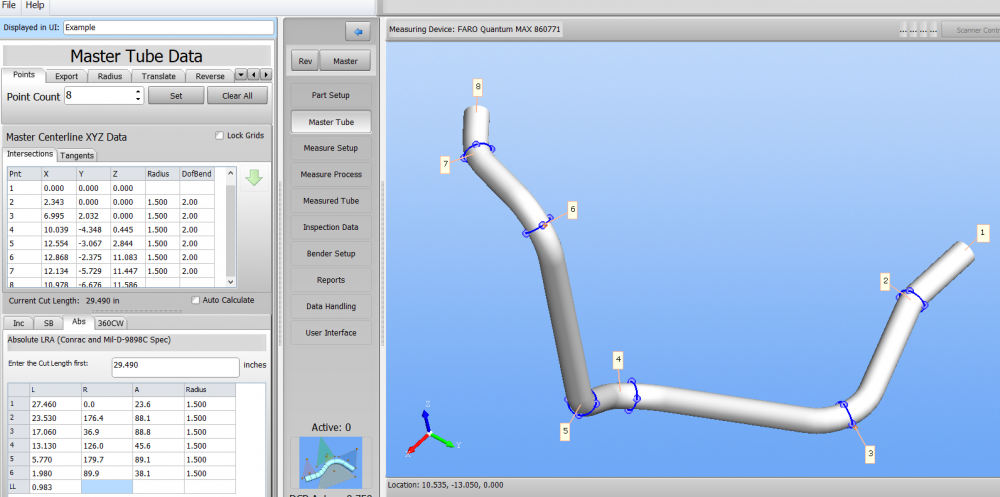

VTube Reverse Calc from MIL-D-9898C Absolute Bender Data to Centerline XYZ Data

Contents[hide] |

General Principals for the Specification

ABSOLUTE LENGTHS

|

This bender data spec uses ABSOLUTE LENGTHS between bends as if they were derived from a tape-measure attached to the Feed axis of a bender. CONRAC benders sometimes had tape measures riveted along the rail of the carriage that moves along the length of the bender. The lengths indicate where each bend begins. |

ABSOLUTE ROTATIONS

|

According to the spec, the bender data uses ABSOLUTE ROTATION data (twist angle between the planes of the bends). It is absolute because it always depends on the rotations in all preceding bends accumulated. The dial on an absolute rotation spindle reads from 0 to 360. |

DRAW BENDING

|

Although it seems to be ambiguous in the specification, most of the part data from this specification assumes DRAW bending versus COMPRESSION bending - which means the LENGTH values move the carriage so that the tube is positioned at the start of each bend (for clamping and drawing around the bend die that rotates with the bend arm) rather than the end of each bend (for clamping with rollers or wipers and compressing around the bend die that does not rotate with the bend arm). |

|

VTube Absolute LRA Data Rules

|

|

Reverse Calc with Absolute LRA Data Requires an Accurate Cut Length

|

Reverse calculation requires an accurate cut length, so this dialog will display to allow you to enter a correct Cut Length before VTube finishes the calculation. This Cut Length value will overwrite the value in the Part Setup menu. |

Calculating the Last Length "LL" value

|

Notice in the MIL-D-9898C bender chart that there is no LAST LENGTH value. However, VTube includes a LL (Last Length) value in the last row.

If these three conditions are true, then you can use this feature to accurately calculate the LL value in this chart. |

Example of Switching from CW to CCW Bend Angles

|

This bender protocol assumes CLOCKWISE as the default bending direction. However, sometimes the part designer creates a tube shape where the bend hand changes from CW to CCW in the middle of the part. See the changing of bend hands in the two images on the right.

|

Apply the rules above to an example.

|

Other Pages

- See also VTube-LASER v2.7

- See also VTube-LASER

- See also VTube-STEP