The Limitations of Qualifying Tube Shapes using Bender Data

|

|

Contents[hide] |

What is Bender Data?

|

Bender data is the data used to setup tube bending machines. Usually, bender data has at three major columns of data - the LENGTH between bends, ROTATION planes between bends, and BEND ANGLE columns. These columns can be used to define the shape of a tube and setup a tube bender.

|

ENVELOPES Qualifying Tube Shapes Are Much Better Than Bender Data Deviations Qualifying Tubes

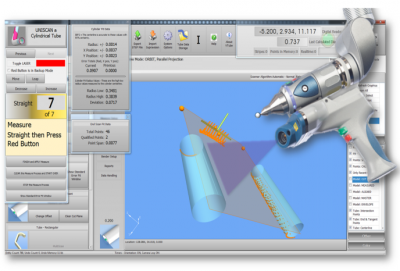

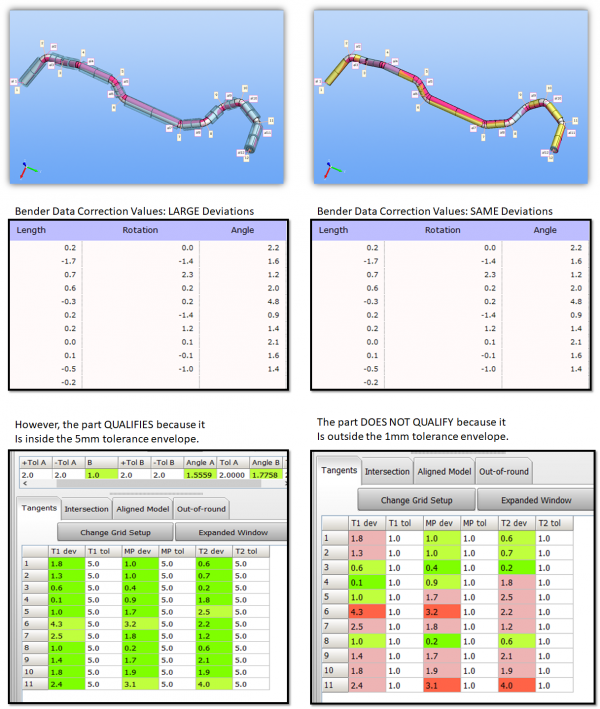

Illustration of the LimitationLook at the bender data on the right. The two sets are not the same because I've made the MEASURED rotations to be exactly one degree away from MASTER data rotations. |

Visually Demonstrate the Problem of Qualifying with Angles

|

So, unless you can perform 3D trigonometry on-the-fly, the answer to the question above isn't obvious. Even if we make a guess, we can't accurately guess at what tolerance envelope value the part would be considered acceptable. |

|

INSIDE THE ENVELOPES: QUALIFIES |

|

OUTSIDE THE ENVELOPES: DOES NOT QUALIFY |

Example 2

|

We show another smaller part with two tolerance envelope setups. |

The Best Data for Qualification

|

The illustrations above show that the best data for tube shape qualification inside an envelope is centerline TANGENT POINT data in the Inspection Data menu and in the Reports menu. |

Typical Industry Tangent Point Envelope Tolerances

|

In working with thousands of customers over the past few decades, we've seen some trends in accepted envelope deviation tolerances. Here are what we commonly see: Aerospace and Automative Fluid Lines

Automotive Exhaust Pipes

Automotive Fluid Lines

Shipbuilding

HVAC

Structural Tubes (Frames)

Tighter TolerancesSometimes customers will require +/-0.75 mm - but this is very rare. We've never seen tube shapes that must be qualified with a deviation tolerance of less than +/- 0.75 mm. |