About this Page

|

This page describes the setup and use of the VTube to AMOB communications.

|

|

The Basics of How It Works

- VTube sends data to the AMOB by exporting a ".VTL" file that the AMOB can read. Communications can be setup through a standard Windows network connection, or you can use a thumb drive.

- The communication is unidirectional toward the bender. It is not possible to RECALL data from the AMOB using this file. The AMOB control only reads this file data.

- The data that is included in the VTL file that the AMOB can read is the BENDER data (X axis, Y Axis, C Axis). The data also includes the diameter, wall thickness, and cut length.

|

|

Communications Setup at the SOCO Bender

- Connect the AMOB bender to the network using a standard Ethernet cable.

- Setup a shared network location either in the AMOB windows control or in a network path on your network.

- If you share a folder on the AMOB control, then create a user with a username and password that can be used to login to the computer from the VTube-LASER computer.

- To import VTL file data that VTube has created, enter the Program Machine Configuration menu. The FARO (or it may be "VTube") button will import transfer files that VTube creates.

|

|

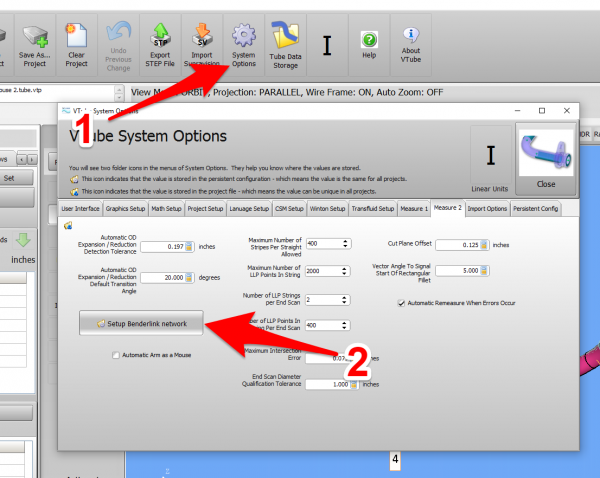

Setup Benderlink at VTube-STEP or VTube-LASER

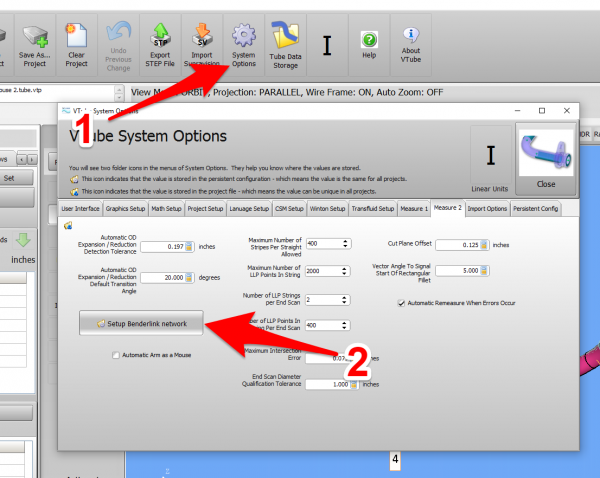

Entering Benderlink Setup

- Enter the VTube System Options menu.

- Enter the Measure 2 tab menu.

- Enter the Setup Benderlink Network menu.

|

|

Setup the Benderlink Network Grid for the SOCO Bender

- Choose an unused row in the grid for a new AMOB bender setup. (Click on the image at the right to see a zoomed image.)

- Assign a bender name that will help operators identify what this bender is. This text will be displayed at the top of the Bender Setup menu.

- Set the protocol to AMOB VTL Data.

- Enter the path to the shared drive or folder in the NetPath field. Use the same location as the AMOB setup. VTube accepts UNC names as well as regular paths with drive letters.

- Enter the IP address in the PING IP ADDRESS field if it is a fixed field. (This is not required. It allows VTube to ping the address to see if the network location is active before trying to open communications.)

- Press Close to save the settings. VTube will save these values to a persistent configuration file that will not change unless you change them in this grid.

|

|

How to SEND MASTER BENDER Data to the AMOB Control from VTube-STEP

|

You can import data into VTube-STEP then send the bender data calculated to the AMOB bender using the VTube Input/Export menu.

|

|

At the VTube-STEP Main Screen

Move to the VTube-STEP computer and follow these steps to transfer the bender data to the AMOB.

- Press the Import/Export button in the navigation pane.

- Find and press the AMOB VTL Data button in the Export section.

|

|

At the AMOB Bender Data Export Window (inside VTube-STEP)

Press the Export button to save a VTL file on the network at the shared path for the AMOB bender.

|

|

How to SEND CORRECTION Data to the AMOB Control from VTube-LASER

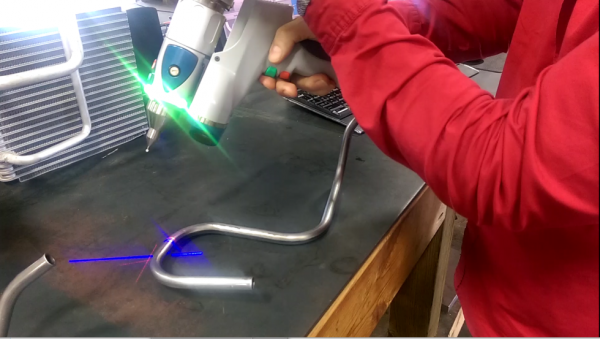

After Bending the Tube

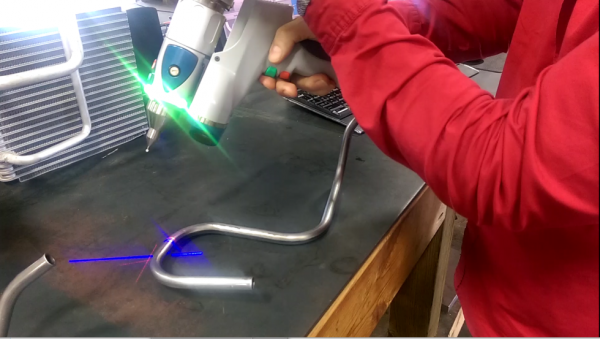

Bend a tube then measure it with VTube-LASER.

</td>

<td width=400>

</td>

</tr>

</table>

</td>

</tr>

</table>

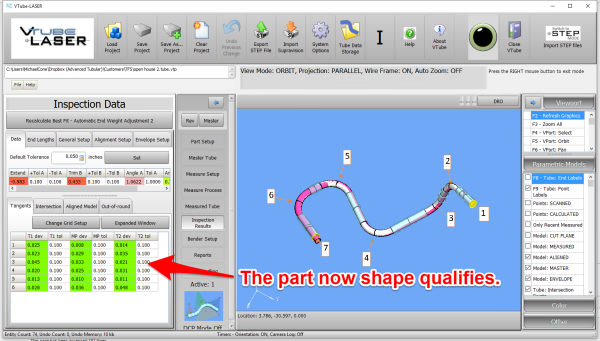

Measure the tube with VTube-LASER

Measure and align the tube to determine if it qualifies by falling within the envelope tolerance for the tube shape.

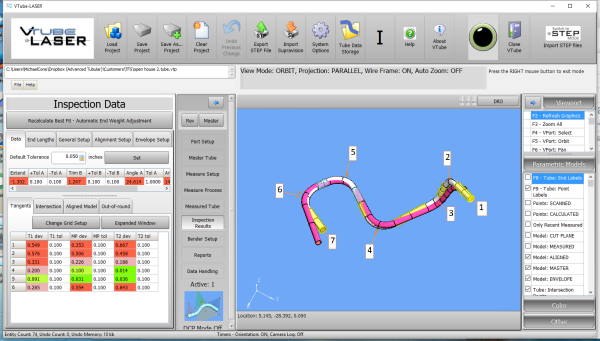

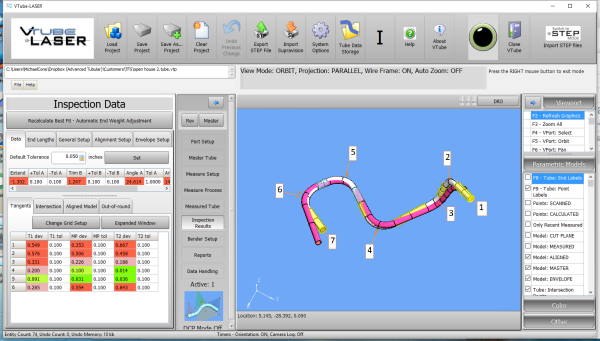

In the VTube-LASER screen shot, you see the actual result of the first tube not qualifying in shape. The red cells in the tangent point grid on the lower left show that the measured tube centerline is out-of-tolerance.

|

|

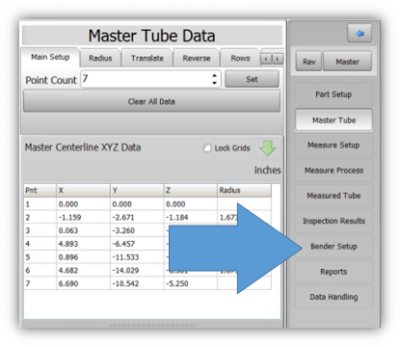

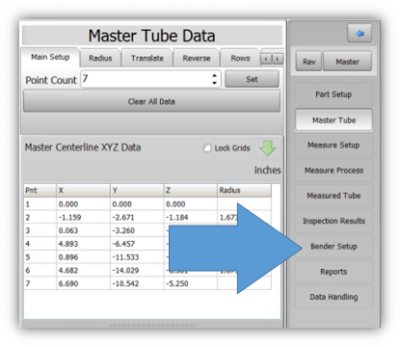

Correct the SOCO with VTube-LASER - Enter BENDER SETUP

Follow these steps in the VTube-LASER:

Press the "BENDER SETUP button in the Navigation Pane.

|

|

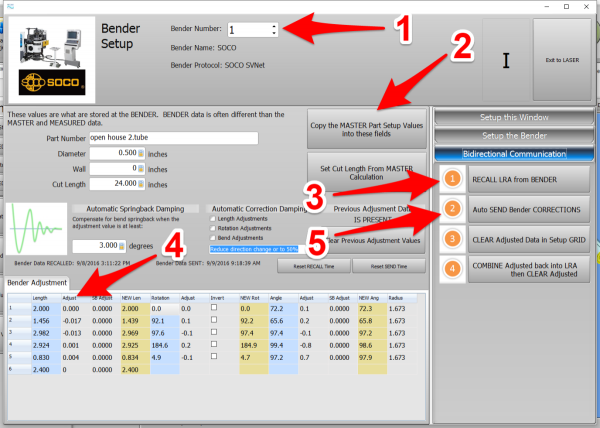

RECALL SOCO YBC data and then SEND CORRECTIONS

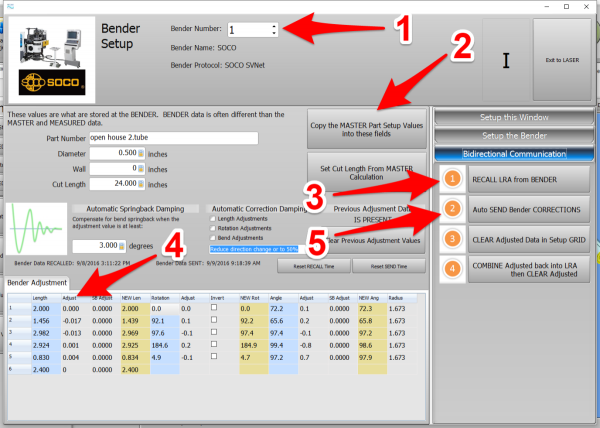

STEP 1 - Set the correct bender number at the top of the window. As of version 2.7, the SOCO SVNet option is available - which means you should see a SOCO bender at the top left corner of the screen.

STEP 2 - If the Part Number is empty, then press the Copy the Master Part Setup values.

STEP 3 - Click on RECALL. This will update the BLUE columns in the Bender Setup.

STEP 4 - You can manually change the ADJUSTMENT values before sending corrections. In this case, we set the first and last Length adjustment to zero in order to keep the start position of the carriage in the same place.

STEP 5 - Click on AUTO SEND. This will send the ORANGE columns to the SOCO bender.

|

|

At the SOCO Bender - Press GO!

Press GO! The SOCO will compile the changes.

You will see a progress bar after you press GO!

|

|

|

The "Auto Compensation Completed" message will appear in the lower right corner.

Bend the corrected part now.

|

|

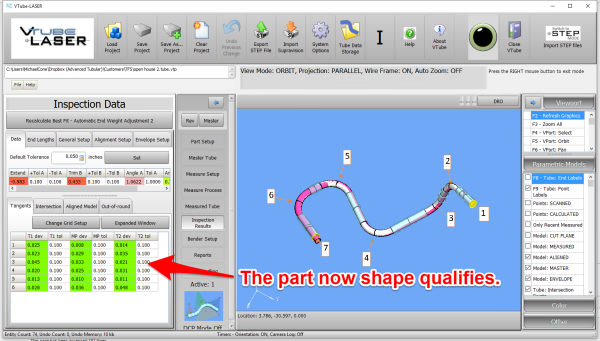

Measure at the VTube-LASER Computer

Measure and align the tube again to determine if it qualifies by falling within the envelope tolerance for the tube shape.

This screen shot shows an actual resulting change after the correction.

|

|

Other Pages

</td>

</tr>

</table>

</td>

</tr>

</table>