Difference between revisions of "VTube Communication for CRIPPA MPF"

(→Communications Setup at the CRIPPA Bender) |

|||

| Line 36: | Line 36: | ||

</td> | </td> | ||

<td width=300> | <td width=300> | ||

| − | |||

| − | |||

</td> | </td> | ||

</tr> | </tr> | ||

Revision as of 15:08, 6 December 2016

About this Page

|

This page describes the setup and use of the VTube to CRIPPA MPF file communications for older CRIPPA benders that do not have the SVNET protocol. |

Protocol

|

VTube-STEP can build CRIPPA MPF files that can be loaded into CRIPPA controls |

Communications Setup at the CRIPPA Bender

|

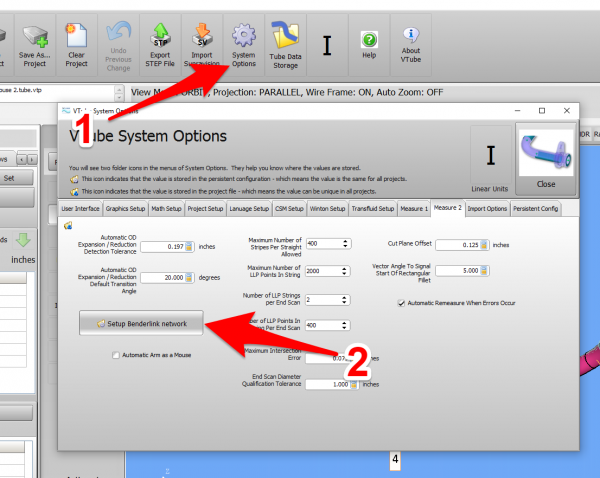

Setup Benderlink at VTube-STEP or VTube-LASER

Entering Benderlink Setup

|

Setup the Benderlink Network Grid for the CRIPPA MPF Bender

|

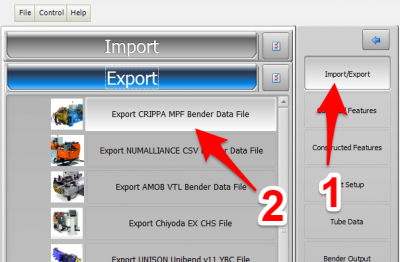

How to SEND MASTER XYZ Data to the CRIPPA Control from VTube-STEP

|

You can import data or models into VTube-STEP then send the calculated LRA bender data to the CRIPPA bender using the VTube EXPORT menu. |

|

STEP 2 - Set the check boxes for the options you want to use, then press Build New Crippa MPF File. |

|

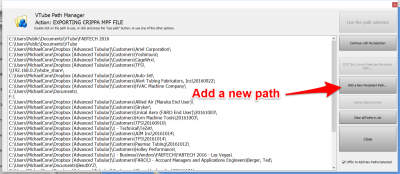

STEP 3 - If the path to the bender is not in the Path Manager list, then you can Add a New Persistent Path to find the path to the bender. If it is in the list, then double click on that path. |

At the SOCO Control

At the SOCO control, enter the SOCO XYZ Screen. With the XYZ Screen open, the SOCO control will understand that it must extract the MASTER XYZ data in the incoming data and import that into the SOCO NVS software.

</td>

<td width=400>

</td>

</tr>

</table>

At the VTube-STEP ComputerMove to the VTube-STEP computer and follow these steps to transfer the XYZ data to the SOCO.

|

How to SEND MASTER XYZ Data to the SOCO Control from VTube-LASER

|

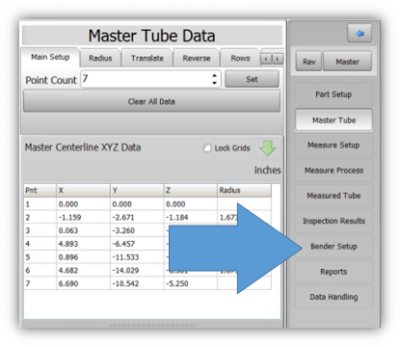

You can also send the new XYZ Centerline data from the VTube-LASER BENDER SETUP menu to the SOCO bender using the VTube Bender Output menu. Enter the XYZ Screen At the SOCO ControlAt the SOCO control, enter the XYZ Screen. With the XYZ Screen open, the SOCO control will understand that it must extract the MASTER XYZ data in the incoming data and import that into the SOCO NVS software. |

|

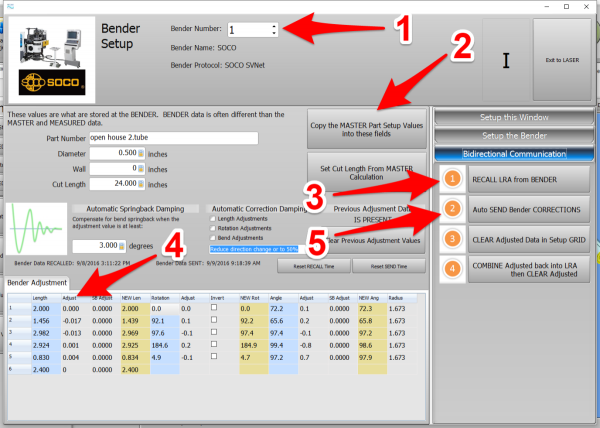

Follow these steps in the VTube-LASER: Press the "BENDER SETUP button in the Navigation Pane. |

|

STEP 1 - Set the correct bender number at the top of the window. As of version 2.7, the SOCO SVNet option is available - which means you should see a SOCO bender at the top left corner of the screen.

|

How to SEND CORRECTION Data to the SOCO Control from VTube-LASER

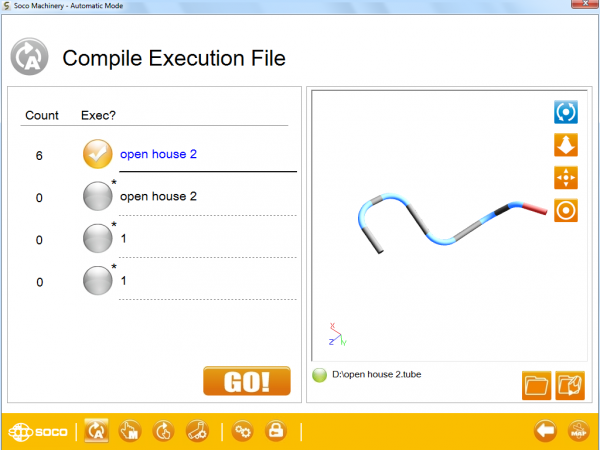

At the SOCO ControlAt the SOCO control, setup and bend the first tube through the YBC and then Compile Execution screen. |

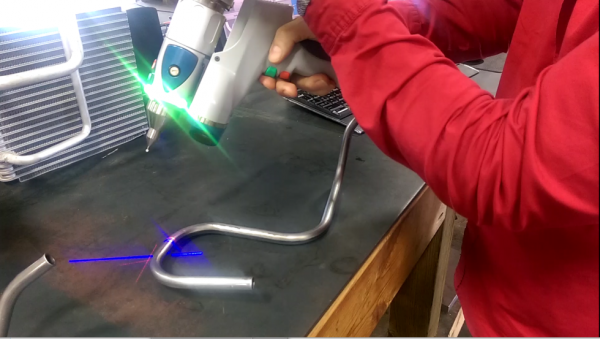

After Bending the TubeAfter the bending cycle is complete, remove the tube from the dies. Leave the bender in AUTO mode. |

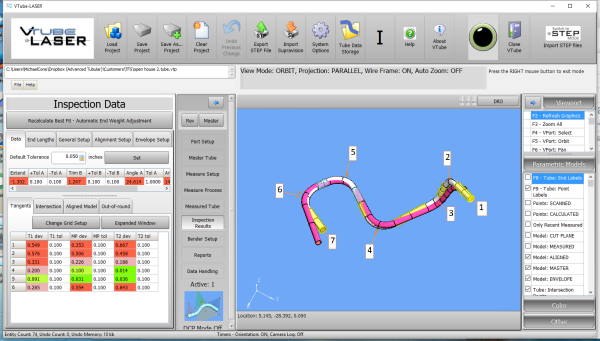

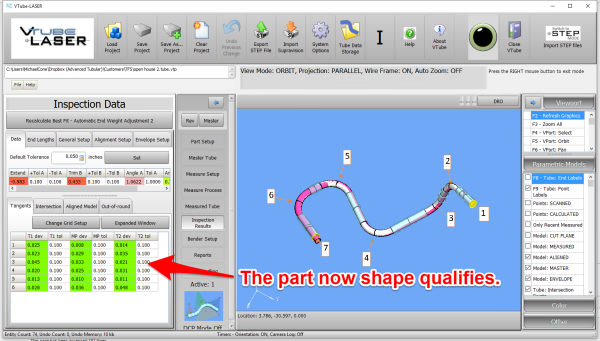

Measure the tube with VTube-LASERMeasure and align the tube to determine if it qualifies by falling within the envelope tolerance for the tube shape.

|

Correct the SOCO with VTube-LASER - Enter BENDER SETUPFollow these steps in the VTube-LASER: Press the "BENDER SETUP button in the Navigation Pane. |

RECALL SOCO YBC data and then SEND CORRECTIONSSTEP 1 - Set the correct bender number at the top of the window. As of version 2.7, the SOCO SVNet option is available - which means you should see a SOCO bender at the top left corner of the screen.

|

At the SOCO Bender - Press GO!Press GO! The SOCO will compile the changes. |

|

The "Auto Compensation Completed" message will appear in the lower right corner. Bend the corrected part now. |

Measure at the VTube-LASER ComputerMeasure and align the tube again to determine if it qualifies by falling within the envelope tolerance for the tube shape.

|

Other Pages

- See VTube-LASER

- See VTube-STEP

- See SOCO for information on the SOCO benders

- See Video 62 - SOCO Communications Video to see an actual corrections loop with a SOCO bender.