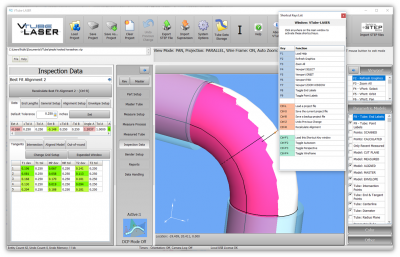

VTube-LASER UniScan Automatic Laser Separation

From ATTWiki

|

UniScan Automatic Separation Tutorial

|

Contents |

About the AUTOMATIC LASER SEPARATION Method for UniScan Mode

|

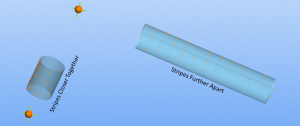

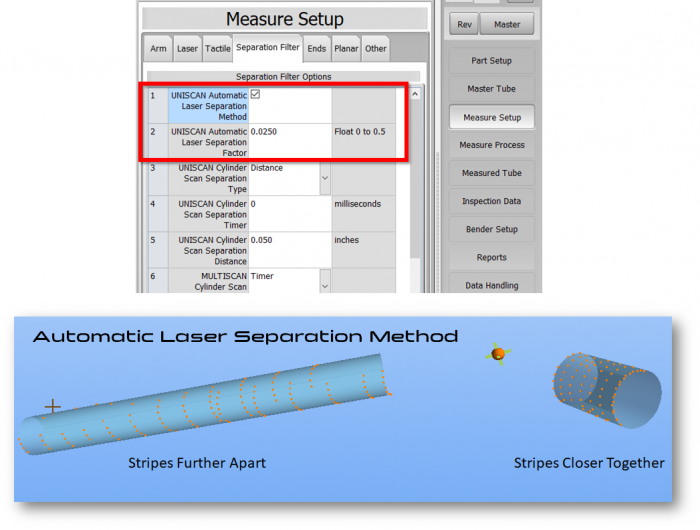

The AUTOMATIC LASER SEPARATION method allows VTube-LASER to automatically control the separation distance between laser stripes based on the known MASTER tube length. |

How AUTOMATIC LASER SEPARATION Method Works

|

Other Pages

- See VTube-LASER Addata ZModem Communications Protocol for more information.

- Back to VTube-LASER

- Back to VTube Software Updates (for LASER Mode)

- See also VTube-STEP

- See also VTube-STEP Revisions

- See VTube-LASER Customer Support Page to download the latest version.

- See the tutorial on DCF - Dual Cylinder Fit

- See the tutorial on DCP - Diameter Cut Planes

- See VTube-LASER Cut Planes

- See How to Measure Tubes Attached to an Evaporator with the DCP Feature