Difference between revisions of "VTube-LASER End Point Deviations"

From ATTWiki

(→How to Understand the Tangent Data) |

(→BEFORE-TRIM Deviations) |

||

| (6 intermediate revisions by one user not shown) | |||

| Line 14: | Line 14: | ||

| − | == Three | + | == Three Types of End Point Deviations == |

<table cellpadding=10> | <table cellpadding=10> | ||

<tr valign=top> | <tr valign=top> | ||

| − | <td width= | + | <td width=300> |

| − | There are three | + | There are three types of end point deviation values calculated during an alignment of the MEASURED to the MASTER tube.<br><br> |

</td> | </td> | ||

<td width=700> | <td width=700> | ||

| Line 31: | Line 31: | ||

<table cellpadding=10> | <table cellpadding=10> | ||

<tr valign=top> | <tr valign=top> | ||

| − | <td width= | + | <td width=300> |

The end length deviations are found at the top of the Inspection menu. | The end length deviations are found at the top of the Inspection menu. | ||

<br><br> | <br><br> | ||

| Line 45: | Line 45: | ||

<table cellpadding=10> | <table cellpadding=10> | ||

<tr valign=top> | <tr valign=top> | ||

| − | <td width= | + | <td width=300> |

These are found in the first T1 value and the last T2 value in the Tangents grid. | These are found in the first T1 value and the last T2 value in the Tangents grid. | ||

<br><br> | <br><br> | ||

| Line 57: | Line 57: | ||

| − | + | ====3D Length Deviations ==== | |

| − | + | ||

| − | == | + | |

| − | + | ||

| − | === | + | |

<table cellpadding=10> | <table cellpadding=10> | ||

<tr valign=top> | <tr valign=top> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

<td width=300> | <td width=300> | ||

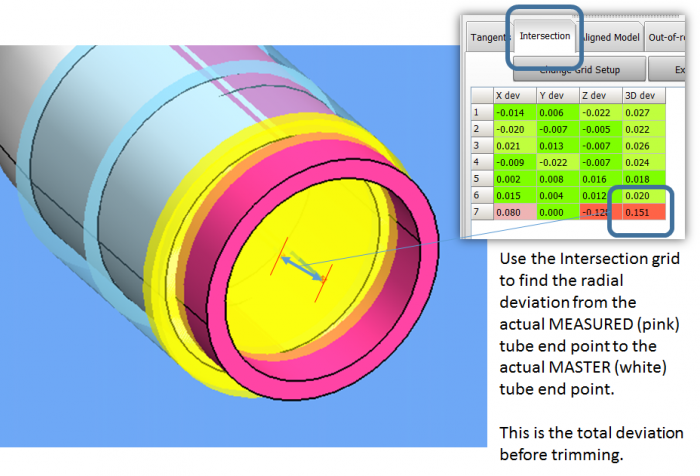

| − | + | These are found in the Intersection grid values. | |

| + | <br><br> | ||

| + | The 3D deviations represent for the first and the last points represent the total radial deviation between the MASTER and the MEASURED end points in this alignment orientation. | ||

</td> | </td> | ||

| − | + | <td width=700> | |

| − | + | [[image:vtl before-trim deviations.png|700px]] | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | <td width= | + | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | [[image: | + | |

</td> | </td> | ||

</tr> | </tr> | ||

| Line 96: | Line 72: | ||

| − | + | <br><br> | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

=Other Pages= | =Other Pages= | ||

* See also [[VTube Intersection Point Tolerances]] | * See also [[VTube Intersection Point Tolerances]] | ||

| + | * [[What are Centerline Tangent Points and Why Are They Important in VTube-LASER?]] | ||

| + | * About [[VTube Intersection Point Tolerances]] | ||

| + | * About [[VTube End Length Offsets]] | ||

| + | * [[The Limitations of Qualifying Tube Shapes using Bender Data]] | ||

* Back to [[VTube-LASER]] | * Back to [[VTube-LASER]] | ||

Latest revision as of 02:09, 31 July 2020

|

|

Contents |

Three Types of End Point Deviations

|

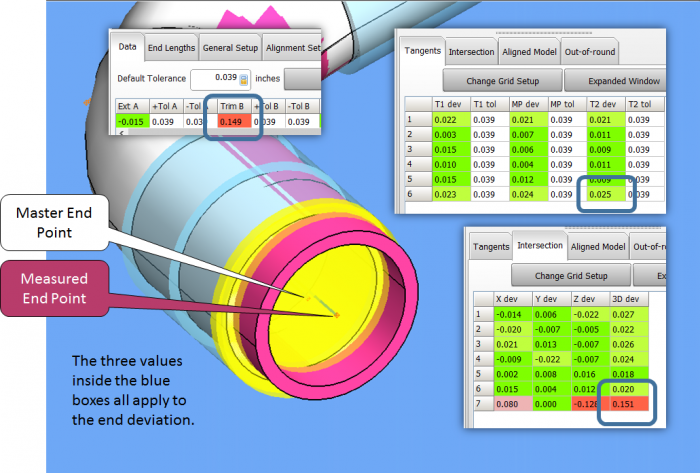

There are three types of end point deviation values calculated during an alignment of the MEASURED to the MASTER tube. |

END LENGTH Deviations

|

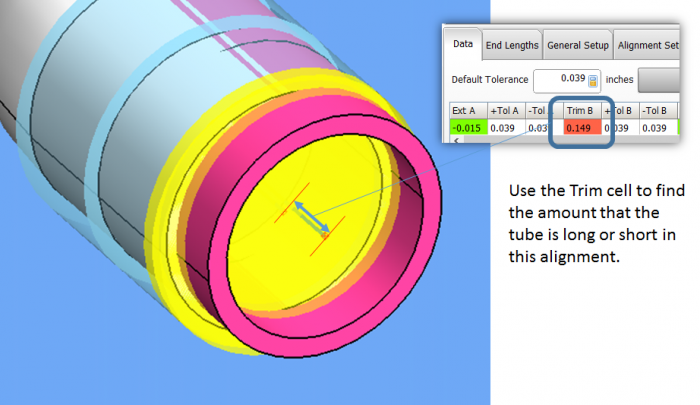

The end length deviations are found at the top of the Inspection menu.

|

AFTER-TRIM Deviations

|

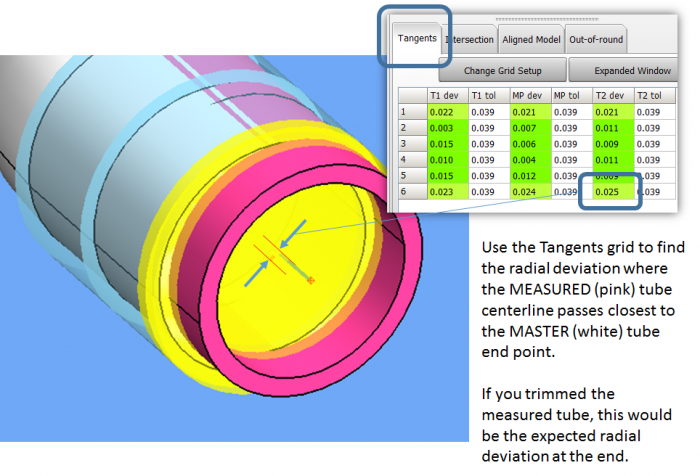

These are found in the first T1 value and the last T2 value in the Tangents grid.

|

3D Length Deviations

|

These are found in the Intersection grid values.

|