Tube Elongation Percentage

|

For some applications, it is important for fabricators to calculate the cut length of parts in advance of bending. The tube elongation percentage value lets you remove elongation from the cut length before bending begins. For example, you may want to quote a project with tens of thousands of pieces - and you want to make a better calculated estimate of total material use.

Applications for Calculating Tube Elongation Percentage

Application 1: For Reuse on New Parts

You could setup and bend the part and measure the cut length before and the length of elongation on the end of the tube after bending for every part. Or you could store this information in VTube's springback compensation library and use it to predict the lengths of future parts with similar materials and setups. (VTube stores the tube elongation % for a setup inside the springback table.)

Application 2: To Unbend Parts with Components in VTube

VTube can unbend tubes in real-time. Unbent parts with holes and components unbent are more useful if they take into account proper tube elongation. For example, you may need to unbend a tube with holes in order to drill the holes before bending. Accounting for elongation becomes critical in this situation.

Follow these steps to use elongation to adjust component locations:

- In VTube-LASER, enter the actual Cut Length used to cut the pre-bent straight stick into the Part Setup Cut Length value.

- Bend the part.

- Measure the part.

- Click on Tube Elongation % in Part Setup.

- Right click.

- Click on Recalc elongation from measured tube minus Cut Length.

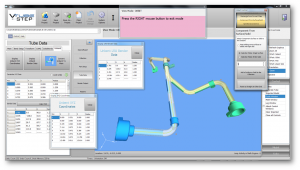

- Switch to VTube-STEP

- Press F2 to redraw the components that were unbent with the tube.

- The components will shift with the new elongation.

- Export the unbent part so that the laser can place the laser cut holes in the right place.

Read More About Tube Elongation

Other Pages

- Back to the VTube-STEP page

- Back to the VTube-LASER page