Difference between revisions of "The Limitations of Qualifying Tube Shapes using Bender Data"

(→Visually Demonstrate the Problem of Qualifying with Angles) |

(→The Best Data for Qualification) |

||

| (47 intermediate revisions by one user not shown) | |||

| Line 38: | Line 38: | ||

</table> | </table> | ||

| − | == | + | == ENVELOPES Qualifying Tube Shapes Are Much Better Than Bender Data Deviations Qualifying Tubes == |

<table cellpadding=10> | <table cellpadding=10> | ||

<tr valign=top> | <tr valign=top> | ||

<td width=500> | <td width=500> | ||

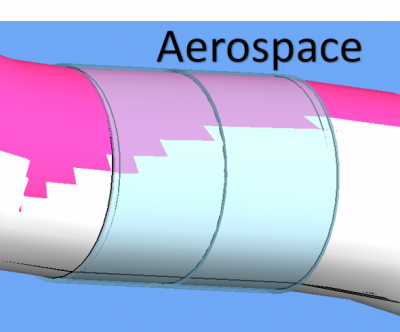

| − | The tube fabrication industry | + | The tube fabrication industry is rapidly abandoning the use of bender data deviations to qualify part shapes for a very good reason.<br><br> |

| − | + | The problem with using bender data deviations for the qualification of a part shape is that it does not help you know if a part is inside or outside of 3D envelopes (or GD&T profiles) for each straight section in a tube shape without additional polar to linear calculations. Spatial envelopes represent the specific path in 3D space where the tube must be inside of in order to not cause a collision or rub itself to failure from vibration.<br><br> | |

| + | In VTube-LASER, this allowed space is called the ENVELOPE as defined by the TANGENT points along each straight in the defined tube (see the image on the right). (Tangent points are where the straights meet the bends.)<br><br> | ||

| + | The ENVELOPE always includes a tolerance of deviation allowed. Think of the deviation as a spherical radius true position from the MASTER centerline. | ||

| + | </td> | ||

| + | <td width=400> | ||

| + | [[image:exhaust_envelope_tolerance.png|400px]]<br> | ||

| + | The above image is an example of an exhaust pipe with a blue band around the straight section. This blue band is the envelope tolerance.<br> | ||

</td> | </td> | ||

</tr> | </tr> | ||

| Line 54: | Line 60: | ||

====Illustration of the Limitation==== | ====Illustration of the Limitation==== | ||

| − | Look at the bender data on the right. The two sets are not the same because I've made the MEASURED rotations to be exactly one degree | + | Look at the bender data on the right. The two sets are not the same because I've made the MEASURED rotations to be exactly one degree away from MASTER data rotations.<br><br> |

| − | Try to answer this question: ''Given a tolerance envelope of 0. | + | Try to answer this question: ''Given a tangent point envelope tolerance envelope of 0.100"'', does this part qualify or not?<br><br> |

| + | This is the problem: There is no way to guess if this part is actually inside its allowed envelope in 3D space without performing some moderately complex trig calculations. | ||

</td> | </td> | ||

<td width=500> | <td width=500> | ||

| Line 70: | Line 77: | ||

<tr valign=top> | <tr valign=top> | ||

<td width=500> | <td width=500> | ||

| − | + | So, unless you can perform 3D trigonometry on-the-fly, the answer to the question above isn't obvious. Even if we make a guess, we can't accurately guess at what tolerance envelope value the part would be considered acceptable.<br><br> | |

It's easy to visually demonstrate the limitation of using bender data to tell us if a part shape falls within the tolerance envelope.<br><br> | It's easy to visually demonstrate the limitation of using bender data to tell us if a part shape falls within the tolerance envelope.<br><br> | ||

| − | |||

| − | |||

| − | |||

| − | |||

</td> | </td> | ||

<td width=300> | <td width=300> | ||

| − | |||

| − | |||

</td> | </td> | ||

</tr> | </tr> | ||

</table> | </table> | ||

| − | |||

<table cellpadding=10> | <table cellpadding=10> | ||

<tr valign=top> | <tr valign=top> | ||

<td width=500> | <td width=500> | ||

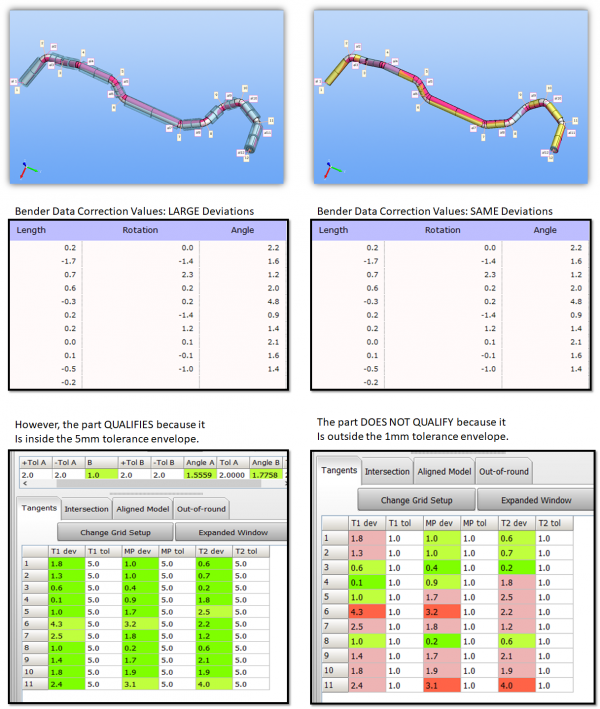

| − | + | '''INSIDE THE ENVELOPES: QUALIFIES'''<br><br> | |

| − | + | Compare the two aligned parts on the image. The white tube is the MASTER. The pink tube is the MEASURED ALIGNED. The blue transparent cylinders that surround the tube are the TOLERANCE ENVELOPES. The tube shape must be within each straight's tolerance envelope to be considered a good shape - or a shape that qualifies.<br><br> | |

| − | + | This first part has 4 inch straights for every straight. (See the LRA data above.)<br><br> | |

| − | + | All the centerlines fall within within the tolerance envelope as defined by the Tangent Grid. The "T1 dev" column values are TANGENT 1 DEVIATIONS, and the "T2 dev" column values are TANGENT 2 DEVIATIONS.<br><br> | |

| + | The tangent points are where the straights meet the bend arcs along the centerline. | ||

</td> | </td> | ||

<td width=300> | <td width=300> | ||

| − | [[image:VTL image 4 | + | [[image:VTL image 4 inch straights.png|500px]]<br><br> |

</td> | </td> | ||

| Line 100: | Line 101: | ||

</table> | </table> | ||

| − | |||

| Line 106: | Line 106: | ||

<tr valign=top> | <tr valign=top> | ||

<td width=500> | <td width=500> | ||

| − | The | + | '''OUTSIDE THE ENVELOPES: DOES NOT QUALIFY'''<br><br> |

| − | + | This second alignment image shows the part with IDENTICAL ANGLES - but the two middle straights are <b>increased in length to 10 inches between bends.</b><br><br> | |

| + | The important point to notice is that both parts have the same diameters, the same rotations, and the same bend angles. However, when increasing the lengths, the parts are in danger of rubbing themselves to failure (or colliding with some part of the application). We only changed the lengths, and the part is now likely to fail if the envelope tolerances represent the maximum allowed space that the tube can use before it collides with something else.<br><br> | ||

| + | See red cells in the Tangent point/Midpoint grid, and yellow tolerance envelopes where the pink (representing the measured aligned part) is breaking through the allowed tolerance.<br><br> | ||

| + | The part is no longer within the tolerance allowed in 3D space - even though all the angle deviations are identical between the two parts.<br><br> | ||

</td> | </td> | ||

<td width=300> | <td width=300> | ||

| − | [[image: | + | [[image:VTL image 4 inch and 10 inch straights.png|500px]]<br><br> |

| + | |||

</td> | </td> | ||

</tr> | </tr> | ||

</table> | </table> | ||

| − | == | + | == Example 2 == |

| − | <table cellpadding=10> | + | <table cellpadding=10 width=900> |

<tr valign=top> | <tr valign=top> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

<td width=300> | <td width=300> | ||

| − | + | We show another smaller part with two tolerance envelope setups.<br><br> | |

| − | </td> | + | Both parts are the identical shape. Look at the bender data deviations. They appear to be quite large according to the standards for companies that like to qualify with angles. However, one part is acceptable, and the other part is not. Depending on the envelope tolerance in the application, the same part may be acceptable.</td> |

| + | <td width=600> | ||

| + | [[image:qualifies5mm.png|600px]]<br><br> | ||

</tr> | </tr> | ||

</table> | </table> | ||

| − | == | + | ==The Best Data for Qualification== |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

<table cellpadding=10> | <table cellpadding=10> | ||

<tr valign=top> | <tr valign=top> | ||

<td width=500> | <td width=500> | ||

| − | + | The illustrations above show that the best data for tube shape qualification inside an envelope is centerline TANGENT POINT data in the Inspection Data menu and in the Reports menu.<br><br> | |

| − | + | [[image:vtube-laser-t1d-mp-t2d-image1.png|500px]]<br><br> | |

| − | + | For more information, see [[What are Centerline Tangent Points and Why Are They Important in VTube-LASER?]] | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

</td> | </td> | ||

<td width=300> | <td width=300> | ||

| − | [[image:vtube-laser- | + | [[image:vtube-laser-tangent-report.png|500px]] |

</td> | </td> | ||

</tr> | </tr> | ||

</table> | </table> | ||

| − | + | =Typical Industry Tangent Point Envelope Tolerances= | |

| − | =Typical Industry Tangent Point Tolerances= | + | |

<table cellpadding=10> | <table cellpadding=10> | ||

<tr valign=top> | <tr valign=top> | ||

<td width=500> | <td width=500> | ||

| − | In working with thousands of customers over the past few decades, we've seen some trends in accepted envelope deviation tolerances. Here are what we commonly see: | + | In working with thousands of customers over the past few decades, we've seen some trends in accepted envelope deviation tolerances.<br><br> |

| + | GD&T Profile Note: GD&T tube profile tolerances are always DOUBLE the VTube-LASER Envelope tolerances. So, a GD&T profile tolerance of 0.120" is VTube-LASER's 0.060" envelope tolerance. All tolerances that we show below are half the GD&T profile tolerances. | ||

| + | |||

| + | Here are what we commonly see: | ||

====Aerospace and Automative Fluid Lines==== | ====Aerospace and Automative Fluid Lines==== | ||

| Line 183: | Line 162: | ||

<tr> | <tr> | ||

<td bgcolor=#9999CC> | <td bgcolor=#9999CC> | ||

| − | Diameter Range | + | Diameter Range |

</td> | </td> | ||

<td bgcolor=#CCCCFF width=200> | <td bgcolor=#CCCCFF width=200> | ||

| Line 192: | Line 171: | ||

<tr> | <tr> | ||

<td> | <td> | ||

| − | 12.7 mm (0.5 inch) diameter tubes or less | + | 12.7 mm (0.5 inch) diameter tubes or less |

</td> | </td> | ||

<td> | <td> | ||

| Line 201: | Line 180: | ||

<tr> | <tr> | ||

<td> | <td> | ||

| − | Greater than 12.7 mm (0.5 inch) | + | Greater than 12.7 mm (0.5 inch) |

</td> | </td> | ||

<td> | <td> | ||

| Line 214: | Line 193: | ||

<tr> | <tr> | ||

<td bgcolor=#9999CC> | <td bgcolor=#9999CC> | ||

| − | Diameter Range | + | Diameter Range |

</td> | </td> | ||

<td bgcolor=#CCCCFF width=200> | <td bgcolor=#CCCCFF width=200> | ||

| Line 226: | Line 205: | ||

</td> | </td> | ||

<td> | <td> | ||

| − | From +/- 2 mm to +/- 3 mm | + | From +/- 2 mm to +/- 3 mm |

</td> | </td> | ||

</tr> | </tr> | ||

| Line 232: | Line 211: | ||

<tr> | <tr> | ||

<td> | <td> | ||

| − | 76 mm to 102 mm | + | 76 mm to 102 mm |

</td> | </td> | ||

<td> | <td> | ||

| Line 241: | Line 220: | ||

<tr> | <tr> | ||

<td> | <td> | ||

| − | Larger then 102 mm | + | Larger then 102 mm |

</td> | </td> | ||

<td> | <td> | ||

| Line 249: | Line 228: | ||

</table> | </table> | ||

| + | |||

| + | |||

| + | ====Automotive Fluid Lines==== | ||

| + | <table cellpadding=10 width=400> | ||

| + | <tr> | ||

| + | <td bgcolor=#9999CC> | ||

| + | Length Range | ||

| + | </td> | ||

| + | <td bgcolor=#CCCCFF width=200> | ||

| + | Envelope Tolerance | ||

| + | </td> | ||

| + | </tr> | ||

| + | |||

| + | <tr> | ||

| + | <td> | ||

| + | Up to 1000mm long after bending | ||

| + | </td> | ||

| + | <td> | ||

| + | From +/- 1 mm to +/- 2 mm | ||

| + | </td> | ||

| + | </tr> | ||

| + | |||

| + | <tr> | ||

| + | <td> | ||

| + | Over 1000mm long after bending | ||

| + | </td> | ||

| + | <td> | ||

| + | +/- 3 mm or greater | ||

| + | </td> | ||

| + | </tr> | ||

| + | |||

| + | </table> | ||

| + | <br><br> | ||

====Shipbuilding==== | ====Shipbuilding==== | ||

| Line 254: | Line 266: | ||

<tr> | <tr> | ||

<td bgcolor=#9999CC> | <td bgcolor=#9999CC> | ||

| − | Diameter Range | + | Diameter Range |

</td> | </td> | ||

<td bgcolor=#CCCCFF width=200> | <td bgcolor=#CCCCFF width=200> | ||

| Line 277: | Line 289: | ||

<tr> | <tr> | ||

<td bgcolor=#9999CC> | <td bgcolor=#9999CC> | ||

| − | Diameter Range | + | Diameter Range |

</td> | </td> | ||

<td bgcolor=#CCCCFF width=200> | <td bgcolor=#CCCCFF width=200> | ||

| Line 299: | Line 311: | ||

<tr> | <tr> | ||

<td bgcolor=#9999CC> | <td bgcolor=#9999CC> | ||

| − | Diameter Range | + | Diameter Range |

</td> | </td> | ||

<td bgcolor=#CCCCFF width=200> | <td bgcolor=#CCCCFF width=200> | ||

| Line 319: | Line 331: | ||

====Tighter Tolerances==== | ====Tighter Tolerances==== | ||

| − | Sometimes customers will | + | Sometimes customers will require +/-0.75 mm - but this is very rare. We've never seen tube shapes that must be qualified with a deviation tolerance of less than +/- 0.75 mm. |

</td> | </td> | ||

Latest revision as of 19:58, 24 January 2020

|

|

Contents |

What is Bender Data?

|

Bender data is the data used to setup tube bending machines. Usually, bender data has at three major columns of data - the LENGTH between bends, ROTATION planes between bends, and BEND ANGLE columns. These columns can be used to define the shape of a tube and setup a tube bender.

|

ENVELOPES Qualifying Tube Shapes Are Much Better Than Bender Data Deviations Qualifying Tubes

Illustration of the LimitationLook at the bender data on the right. The two sets are not the same because I've made the MEASURED rotations to be exactly one degree away from MASTER data rotations. |

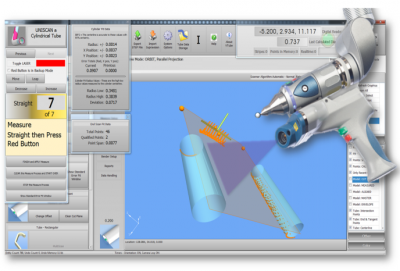

Visually Demonstrate the Problem of Qualifying with Angles

|

So, unless you can perform 3D trigonometry on-the-fly, the answer to the question above isn't obvious. Even if we make a guess, we can't accurately guess at what tolerance envelope value the part would be considered acceptable. |

|

INSIDE THE ENVELOPES: QUALIFIES |

|

OUTSIDE THE ENVELOPES: DOES NOT QUALIFY |

Example 2

|

We show another smaller part with two tolerance envelope setups. |

The Best Data for Qualification

|

The illustrations above show that the best data for tube shape qualification inside an envelope is centerline TANGENT POINT data in the Inspection Data menu and in the Reports menu. |

Typical Industry Tangent Point Envelope Tolerances

|

In working with thousands of customers over the past few decades, we've seen some trends in accepted envelope deviation tolerances. Here are what we commonly see: Aerospace and Automative Fluid Lines

Automotive Exhaust Pipes

Automotive Fluid Lines

Shipbuilding

HVAC

Structural Tubes (Frames)

Tighter TolerancesSometimes customers will require +/-0.75 mm - but this is very rare. We've never seen tube shapes that must be qualified with a deviation tolerance of less than +/- 0.75 mm. |