Difference between revisions of "The Limitations of Qualifying Tube Shapes using Bender Data"

(→Visually Demonstrate the Problem of Qualifying with Angles) |

(→Visually Demonstrate the Problem of Qualifying with Angles) |

||

| Line 72: | Line 72: | ||

Unless you can perform 3D trigonometry mentally on-the-fly, the answer to the question above isn't obvious. Even if we make a guess, we can't accurately guess at what tolerance envelope value the part would be considered acceptable.<br><br> | Unless you can perform 3D trigonometry mentally on-the-fly, the answer to the question above isn't obvious. Even if we make a guess, we can't accurately guess at what tolerance envelope value the part would be considered acceptable.<br><br> | ||

It's easy to visually demonstrate the limitation of using bender data to tell us if a part shape falls within the tolerance envelope.<br><br> | It's easy to visually demonstrate the limitation of using bender data to tell us if a part shape falls within the tolerance envelope.<br><br> | ||

| + | </td> | ||

| + | <td width=300> | ||

| + | </td> | ||

| + | </tr> | ||

| + | </table> | ||

| + | |||

| + | <table cellpadding=10> | ||

| + | <tr valign=top> | ||

| + | <td width=500> | ||

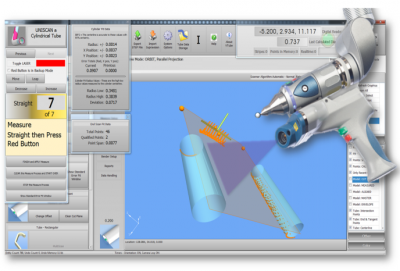

Compare the two aligned parts on the image. The white tube is the MASTER. The pink tube is the MEASURED ALIGNED. The blue transparent cylinders that surround the tube are the TOLERANCE ENVELOPES. The tube shape must be within each straight's tolerance envelope to be considered a good shape - or a shape that qualifies.<br><br> | Compare the two aligned parts on the image. The white tube is the MASTER. The pink tube is the MEASURED ALIGNED. The blue transparent cylinders that surround the tube are the TOLERANCE ENVELOPES. The tube shape must be within each straight's tolerance envelope to be considered a good shape - or a shape that qualifies.<br><br> | ||

This first part has 4 inch straights for every straight. (See the LRA data above.)<br><br> | This first part has 4 inch straights for every straight. (See the LRA data above.)<br><br> | ||

| Line 83: | Line 92: | ||

</tr> | </tr> | ||

</table> | </table> | ||

| + | |||

Revision as of 15:36, 29 March 2018

|

|

Contents |

What is Bender Data?

|

Bender data is the data used to setup tube bending machines. Usually, bender data has at three major columns of data - the LENGTH between bends, ROTATION planes between bends, and BEND ANGLE columns. These columns can be used to define the shape of a tube and setup a tube bender.

|

The Limitations of Bender Data for Qualifying Tube Shapes

|

The tube fabrication industry rarely uses bender data to qualify part shapes for a very good reason. |

Illustration of the LimitationLook at the bender data on the right. The two sets are not the same because I've made the MEASURED rotations to be exactly one degree away from MASTER data rotations. |

Visually Demonstrate the Problem of Qualifying with Angles

|

Unless you can perform 3D trigonometry mentally on-the-fly, the answer to the question above isn't obvious. Even if we make a guess, we can't accurately guess at what tolerance envelope value the part would be considered acceptable. |

|

Compare the two aligned parts on the image. The white tube is the MASTER. The pink tube is the MEASURED ALIGNED. The blue transparent cylinders that surround the tube are the TOLERANCE ENVELOPES. The tube shape must be within each straight's tolerance envelope to be considered a good shape - or a shape that qualifies. |

|

This second alignment image shows the part with IDENTICAL ANGLES - but the two middle straights are lengthened to 10 inches between bends. |

The Best Data for Qualification

|

The best data for qualification is centerline TANGENT POINT and MIDPOINT data in the Inspection Data menu and in the Reports menu. |