Difference between revisions of "Scanning on a NEWPORT type table"

From ATTWiki

(→The Impact on Cylinder Calculations) |

(→Potential For Outliers At Normal Relfective Surfaces) |

||

| Line 65: | Line 65: | ||

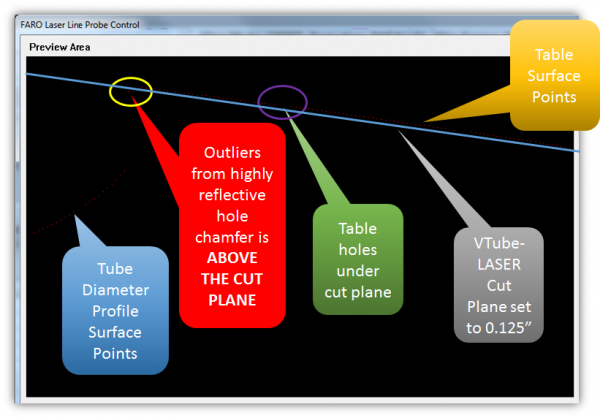

Notice that the chamfer that is normal to the laser and the camera is showing a bubble outlier. (Click on the image to see a closer view of this screen shot.) The effect is that the camera sees points where the is no object in space.<br><br> | Notice that the chamfer that is normal to the laser and the camera is showing a bubble outlier. (Click on the image to see a closer view of this screen shot.) The effect is that the camera sees points where the is no object in space.<br><br> | ||

One way to overcome this bubble is to increase the cut plane offset. In this case, the offset was set to 1 inch.<br><br> | One way to overcome this bubble is to increase the cut plane offset. In this case, the offset was set to 1 inch.<br><br> | ||

| − | Another way to overcome this issue is to place a darker surface (a mat or paint) in the table.</td> | + | Another way to overcome this issue is to place a darker surface (a mat or paint) in the table. |

| + | [[image:vtube-laser_closeup_outliers.png|200px]]</td> | ||

<td> | <td> | ||

[[image:Faro_LLP_Control_Newport_Table.png|600px]] | [[image:Faro_LLP_Control_Newport_Table.png|600px]] | ||

| Line 74: | Line 75: | ||

</table> | </table> | ||

<br> | <br> | ||

| − | |||

== The Impact on Cylinder Calculations== | == The Impact on Cylinder Calculations== | ||

Revision as of 19:13, 13 April 2016

|

NEWPORT Tables

| Scanning on NEWPORT tables is possible with the FARO scanner system, but care must be taken because of the high reflectivity of the surfaces in the drilled and tapped holes. | |

Scanning Example

|

The image on right shows an example of scanning a tube on a Newport table. | |

Potential For Outliers At Normal Relfective Surfaces

The Impact on Cylinder Calculations

| If VTube uses these outliers to calculate the diameter, then often the cylinder fit math will fail to find a centerline - and VTube will ask you to remeasure the straight where the problem is occuring. | |

Other Pages

- Back to the VTube-STEP page

- Back to the VTube-LASER page