Revision: Benderlink for Chiyoda/Keins 5.84

Contents |

NEW FEATURE: RECALCULATION OF INCOMING STRAIGHTS WITH NEW CENTERLINE RADII

BACKGROUND

-

When importing Supravision data to convert to Chiyoda or Keins FPB Data, there is the potential for the following scenarios:

- The radius values in the Supravision data is slightly different than the radius values for the tools on the bender.

- There are more radius values in the Supravision data than the bender allows.

ISSUE

-

This creates a problem where the LENGTHS between bends that are converted to FEED data are no longer precise.

SOLUTION

-

The solution is for Benderlink to give the opportunity to calculate new FEED distances when XYZ data exists in the Supravision data.

HOW IT WORKS

|

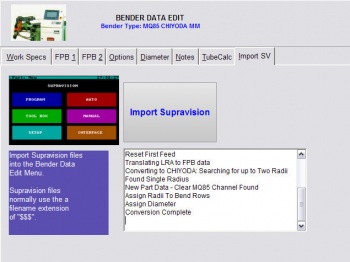

STEP 1 Open the import SV menu and press the Import Supravision button |

|

|

STEP 2 Choose the Supravision file to import |

|

|

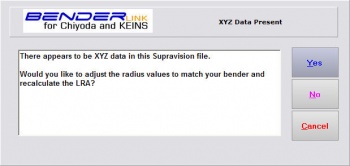

STEP 3 Benderlink checks the number of XYZ points with the bend count |

If there is a match (points = bends + 2) then this window is displayed. |

|

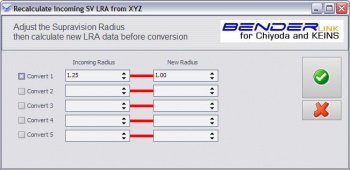

STEP 4 Examine and modify the radii values |

You can change any radius values found in the Supravision data by checking the check box, then entering a new radius value in the right box for each radius change. |

|

STEP 5 Press the green button |

This closes the window, replaces the radii values, then performs a new XYZ to LRA calculation. |

|

STEP 6 Plug the USB Flash Drive In |

Plug the USB flash drive into the NEW target computer. |

|

STEP 7 Copy to C:\CNC |

Use Windows Explorer to copy the data to the same folder on the target computer's drive. The folder should be "c:\cnc" |

|

STEP 8 Run the Hardware Key DRIVER |

Browse to the c:\cnc\key folder and run "hdd32.exe." This program is a hardware key driver file that needs only to be run once. It may require that you be logged in as a user with administrative rights. Download the latest hdd32.exe file here: http://www.advancedtubular.com/key/hdd32.exe |

|

STEP 9 Transfer Hardware Key |

Remove the hardware key from the parallel port of the CNC Bender operator station (inside the operator station enclosure). Plug it into the new computer parallel port. |

|

STEP 10 Set the NEW Computer IP Address |

Use the Windows Start / Connect To menu to configure the TCP/IP address of the port that will connect to the bender. Set that port to a fixed IP address of 192.168.0.199. Any valid setting under 200 for the last octet will work. The operator station uses .200 as the address. If the operator station is not powered on, or is not attached to the bender network, then you can also use address .200. |

|

STEP 11 Plug Ethernet |

Plug an ethernet cable (RJ45 type) between the new computer's NIC port and the Netgear switch in the electronics cabinet using a standard ethernet cable. |

|

STEP 12 CNC Bender Software |

Start CNC Bender software by finding the CNCBender.exe program in the c:\cnc folder and double clicking on it (or select the file and press Enter). |

DOWNLOAD SETUP FILE

-

The hyperlink to the setup software is http://www.advancedtubular.com/benderlnk5/setup_blink5_82.exe