Difference between revisions of "How to Measure and Clock Tube Legs Coming Out of Tubes"

From ATTWiki

| Line 20: | Line 20: | ||

<tr valign=top> | <tr valign=top> | ||

<td width=300> | <td width=300> | ||

| − | *To | + | *To measure the clocking angle of holes that will receive tube legs inserted into other tubes, we recommend that you create plugs that insert perpendicular in the drilled holes. Make the plug at least a couple of inches long. |

| + | (The longer, the better.)<br><br> | ||

</td> | </td> | ||

<td> | <td> | ||

Revision as of 15:19, 9 August 2018

|

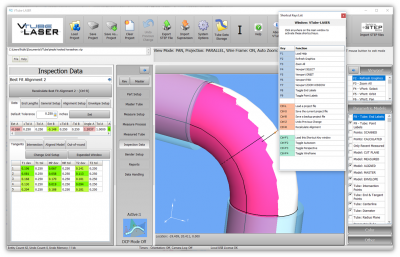

Measure and Clock Tube Legs |

(The longer, the better.) |

|

|

|

|

|

|

Other Pages

- Back to VTube-LASER