Difference between revisions of "How to Measure and Clock Tube Legs Coming Out of Tubes"

From ATTWiki

(Created page with "<table> <tr cellpadding=10> <td width=225> 300px ==Measure and Clock Tube Legs== </td> <td width=300> image:vtube-laser_v2.7_screensh...") |

|||

| Line 19: | Line 19: | ||

<tr valign=top> | <tr valign=top> | ||

<td width=300> | <td width=300> | ||

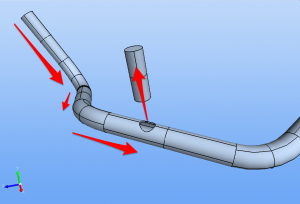

| − | *To check the clocking of holes in tubes, we recommend that you create plugs that insert in the hole. Make the plug at least a couple of inches long. | + | *To check the clocking of holes in tubes, we recommend that you create plugs that insert in the hole. Make the plug at least a couple of inches long.<br><br> |

| − | + | * Then create a master tube with the shape that finishes with the plug as the last or first leg.<br><br> | |

| − | + | * Then measure that part of the tube to see the clocking to the previous bend angle.<br><br> | |

| − | * Then create a master tube with the shape that finishes with the plug as the last or first leg. | + | |

| − | + | ||

| − | * Then measure that part of the tube to see the clocking to the previous bend angle. | + | |

</td> | </td> | ||

Revision as of 16:50, 15 March 2018

|

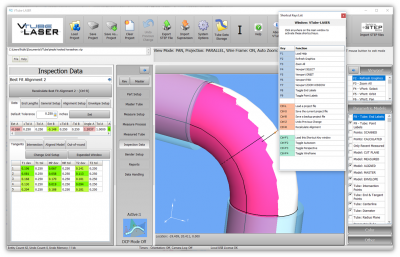

Measure and Clock Tube Legs |

|

Other Pages

- Back to VTube-LASER