Difference between revisions of "Helical coil"

(→Coil Radius) |

|||

| Line 17: | Line 17: | ||

Other factors include the distance between the two opposing rollers in the front die and material composition and wall thickness. The largest contributor to the coil radius is the bend arm angle during push bending. | Other factors include the distance between the two opposing rollers in the front die and material composition and wall thickness. The largest contributor to the coil radius is the bend arm angle during push bending. | ||

<br><br> | <br><br> | ||

| + | |||

| + | ==Coiled Tube Sample== | ||

This is a sample tube coil that was bent using both [[draw bend]]ing and [[push bend]]ing.<br><br> | This is a sample tube coil that was bent using both [[draw bend]]ing and [[push bend]]ing.<br><br> | ||

[[image:coiltube_sample.jpg|300px]] | [[image:coiltube_sample.jpg|300px]] | ||

Revision as of 04:33, 2 January 2009

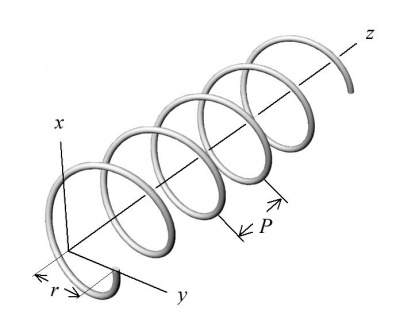

A helical coil has a centerline shape of a helix. A helix (pl: helixes or helices) is a curve that forms a spiral or a coil in space.

CNC Bender uses push bending with a rotational twist in the Rotation axis to create helical tube or pipe coils used in often heat transfer and immersion applications.

Contents |

Coil Pitch

The pitch of a helix is the width of one complete helix turn, measured along the helix axis.

With CNC Bender the pitch of a tube coil is most affected by the coil twist ratio in the Push Bend Profile Table.

Increase the ratio value to increase the pitch in a coiled tube.

Coil Radius

The radius of a helical tube shape is controlled mainly by the bend arm angle during push bending.

Other factors include the distance between the two opposing rollers in the front die and material composition and wall thickness. The largest contributor to the coil radius is the bend arm angle during push bending.

Coiled Tube Sample

This is a sample tube coil that was bent using both draw bending and push bending.

Other Pages

- See CNC Bender

- See Push Bending

- See Push Bending Profile Table