Difference between revisions of "FARO CAM2"

(→Benefit 2 - Built in Feedback to Increase Confidence in Data) |

(→Benefit 2 - Built in Feedback to Increase Confidence in Data) |

||

| Line 72: | Line 72: | ||

==== Benefit 2 - Built in Feedback to Increase Confidence in Data ==== | ==== Benefit 2 - Built in Feedback to Increase Confidence in Data ==== | ||

VTube-LASER has special procedures that help anticipate the level of confidence you will have in the incoming data. There are series of crosschecks just for measuring tubing, both mathematical and on-screen, that allow users to know if the data is good. <br><br> | VTube-LASER has special procedures that help anticipate the level of confidence you will have in the incoming data. There are series of crosschecks just for measuring tubing, both mathematical and on-screen, that allow users to know if the data is good. <br><br> | ||

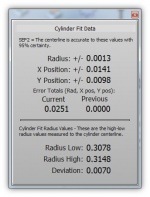

| + | The Cylinder Fit Data window shows the wobble deviation values by reporting the potential X and Y deviation at the Standard Deviation X 2 level. This helps us know the deviation of the 95% of the surface points that were used to find the cylinder centerline. | ||

</td> | </td> | ||

Revision as of 20:16, 12 January 2013

|

FARO CAM2 software for measuring prismatic shapes. It is used by tube fabrication customers on FARO arms along with VTube-LASER to measure components around tube shapes. |

CAM2 Measure 10 and VTube-LASER Working Together

Measure Tubes with VTube then Export to CAM2 FilesSince year 2010, FARO has started selling VTube-LASER as a quicker method of tube measuring. (FARO is the exclusive distributor for VTube-LASER in North and South America.) General Workflow for VTube to CAM2The workflow process is to scan a tube with VTube, then continue with measuring components around the tube in CAM2. The method is to leave the tube in the same location when measuring in the two programs. The correct position in space is transferred into CAM2 Measure 10 as long as the tube is not moved. |

Export as Parametric Tubes

|

VTube-LASER exports CAM2 Measure 10 parametric tube files for measuring brackets and components around the tube. Both the MASTER and the MEASURED tube shapes can be exported in the FILE tab sub-menus for each tube centerline. |

Importing to CAM2

|

Use the Import/Export option in the File pulldown menu to import the CAM2 file that VTube builds. The tube shapes can be imported into CAM2 as NOMINAL (VTube MASTER), or ACTUAL (VTube MEASURED). |

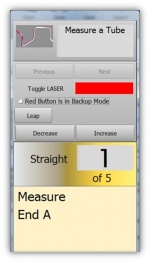

Benefits of Using VTube-LASER for Tube Measurement

Benefit 1 - Built-in Automated Process for Measuring TubesThe benefit of using VTube-LASER for tube scanning is that VTube-LASER has built-in knowledge of measuring tube shapes. When you measure a tube with VTube, the methods for gathering the information and calculating the centerline, intersection points, and bend data are preprogrammed as a series of steps that never have to be scripted by a user into VTube-LASER. VTube knows what you should give it, and it will always request that data in order using the Tube Measuring menu. Benefit 2 - Built in Feedback to Increase Confidence in DataVTube-LASER has special procedures that help anticipate the level of confidence you will have in the incoming data. There are series of crosschecks just for measuring tubing, both mathematical and on-screen, that allow users to know if the data is good. |

CAM2Q (release about 2008)

|

This version of CAM2 software released in 2008 (See FARO news release). |

CAM2 Measure X - (released about 2005)

|

CAM2 Measure X1 was released in 2005 (See FARO news release). |

|

Communications between CAM2 Measure X and benders is through the EXPORT - XYZ - TXT feature to Benderlink for FARO software. |