Difference between revisions of "DOCS"

(→Communication with Supravision Network Protocol) |

(→Communication with Supravision Network Protocol) |

||

| Line 113: | Line 113: | ||

==Communication with Supravision Network Protocol== | ==Communication with Supravision Network Protocol== | ||

| − | See this link for information on which version of DOCS will communicate using SVNET: [http://advancedtubular.wiki/index.php?title=Supravision_Network_Protocol#DOC_Versions_to_Use_for_SVNET] | + | See this link for information on which version of DOCS will communicate using SVNET: [http://www.advancedtubular.wiki/index.php?title=Supravision_Network_Protocol#DOC_Versions_to_Use_for_SVNET] |

==Principles for Corrections Loops with SVNET and DOCS== | ==Principles for Corrections Loops with SVNET and DOCS== | ||

Revision as of 20:49, 27 July 2015

DOCS is a software package that is sold by Romer. The word "DOCS" means Data Overlay Camera System.

Contents |

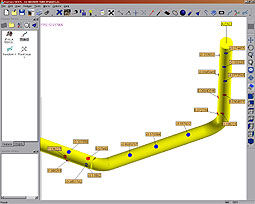

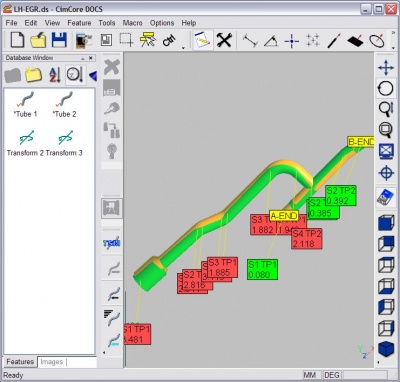

Screen Image

This is a screen image from our test license of DOCS software.

Solid Model Output

DOCS can output a solid model that can be imported into VTube-STEP. However it is our experience that the model is not as precise as models from other solid model programs (like SolidWorks).

When calculating centerline data from DOCS solids, you may need to increase the projection tolerance value in the collection grid to make the calculation work.

Comparing DOCS to Supravision

Supravision and DOCS are developed by Romer. Supravision is the older legacy program for tube measurement. This matrix offers a comparison between the two software packages:

|

DOCS Software |

Supravision Software |

|

Active - Continued development |

Static - No more development |

|

Allows for the measurement of tube data and non-tube data surrounding the tube - including brackets and other fabrications |

Measures only tube shapes |

| Because it is more powerful, it is also more complex. Thus - this software takes longer to learn. |

Supravision is very easy to learn. |

|

Can use contact or non-contact measurement |

Can only use non-contact measurement of tube shapes |

|

Can measure multiple tubes in a single DOCS file |

Can measure one tube per Supravision file |

|

Romer charges a fee for every bender connected to DOCS. |

There is no charge from ROMER for connection through Supravision. |

|

Tube Shop Manager (TSM) is an optional feature in DOCS. You must purchase TSM if you want to measure and correct tubes in DOCS software. |

Tube measurement is standard in Supravision (because that is all Supravision can do). |

Our Recommendation

As of December, 2007, we have been given a license of DOCS software for evaluation and testing with our Benderlink software. This is our recommendation:

- Be prepared for the increased complexity of the program.

- If you are a Supravision owner, then we recommend that you view DOCS in action before making a decision. Specifically ask for a tube demo. We also recommend that you compare DOCS to our VTube-LASER software before making a decision.

- Also, we recommend that our customers be careful to receive a quotation for all the options that you will expect with DOCS (like TSM and a sufficient number of bender licenses if you plan to connect to benders through Benderlink).

Communication with Supravision Network Protocol

See this link for information on which version of DOCS will communicate using SVNET: [1]

Principles for Corrections Loops with SVNET and DOCS

|

Principles |

Reasons |

|

If the data at the bender control has changed and...

|

A RECALL from a bender clears the results of a measure - so it is important to RECALL the latest bender data from the bender as a first step through Benderlink if the CLRA data in DOCS does not match the bender's LRA values. If the bender data has changed at the bender control before the current part is measured for correctness, then follow these steps:

|

|

After a RECALL from the bender...

|

|

|

If you have a version of DOCS of 2.2 or 2.3 and previous to Dec 20, 2007 in file date, then...

|

Earlier DOCS versions of 2.3 change the NOMINAL LRA data during a RECALL. (Only the CORRECTED LRA data should be updated.) |

|

DOCS reports a corrupted data transmission if the data from a RECALL DEFAULT TUBE has a diameter of ZERO. |

Be sure that the data at the bender has a non-zero diameter before attempting to RECALL data. |