Difference between revisions of "CNC Bender v12.4"

From ATTWiki

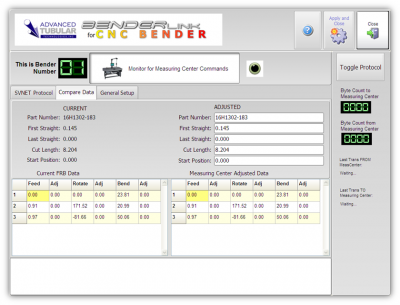

(→25px ENHANCED: Benderlink) |

(→25px Other Changes) |

||

| (4 intermediate revisions by one user not shown) | |||

| Line 23: | Line 23: | ||

<tr> | <tr> | ||

<td width=400> | <td width=400> | ||

| − | * DOCS software may send a changed rotation direction which could crash a bender during correction.<br><br>CNC Bender Benderlink intercepts this condition and automatically corrects the direction if rotatio data is already programmed into the control. The problem especially occurs around the 180 degree rotation area. | + | * DOCS software may send a changed rotation direction which could crash a bender during correction.<br><br>CNC Bender Benderlink intercepts this condition and automatically corrects the direction if rotatio data is already programmed into the control. The problem especially occurs around the 180 degree rotation area.<br><br>This intercept and correction action is effective for any measuring center sending data to CNC Bender using either SVNET or Eaton Leonard Laservision protocols. |

<br> | <br> | ||

* The Compare Data tab is now the first one to display when entering Benderlink from Tube Shape. | * The Compare Data tab is now the first one to display when entering Benderlink from Tube Shape. | ||

| Line 59: | Line 59: | ||

<tr> | <tr> | ||

<td width=400> | <td width=400> | ||

| − | * | + | * The HAND BENDER MODE of CNC Bender is enhanced to allow for Bending without the Feed axis following. This is helpful for applications where the last bend will pull the chuck into the pressure die or inside wiper die. |

</td> | </td> | ||

<td width=300> | <td width=300> | ||

Latest revision as of 22:41, 7 October 2013

v12.4 - October 7, 2013

|

ENHANCED: Benderlink

ENHANCED: Benderlink

|

ENHANCED: Extended Timing Control for Servo Modules

ENHANCED: Extended Timing Control for Servo Modules

|

The SMT operator stations now process data more quickly than in earlier modules. This version of CNC Processor now more carefully governs the timing of all data sent to the servo modules to prevent occasional TCP/IP errors due to CNC Bender outpacing the servo modules.

|

Other Changes

Other Changes

|

Other Pages

- Back to CNC Bender

- Back to CNC Bender Software Updates

- See CNC Bender Customer Service Page for an update.

- See CNC Bender General Information

- See Teach Mode

- See Custom Commands