Difference between revisions of "CNC Bender v12-20130723"

(→v12-20130722) |

|||

| (7 intermediate revisions by one user not shown) | |||

| Line 15: | Line 15: | ||

__NOTOC__ | __NOTOC__ | ||

| − | See [http://advancedtubular.com/customers/cncbender/page-downloads/v12- | + | See [http://advancedtubular.com/customers/cncbender/page-downloads/v12-20130723.html CNC Bender Customer Service Page] for an update. |

===[[image:Check.jpg|25px]] NEW: Any Command (COMDEF) can be taught to ignore Cycle Hold === | ===[[image:Check.jpg|25px]] NEW: Any Command (COMDEF) can be taught to ignore Cycle Hold === | ||

| Line 23: | Line 23: | ||

This new feature allows selected COMDEFs to run in the processlist without pausing during CYCLE HOLD. The reason for this new capability is that some customers require that their benders be equipped with palm buttons that must be held during any part of the bending with pinch-point motion.<br><br> | This new feature allows selected COMDEFs to run in the processlist without pausing during CYCLE HOLD. The reason for this new capability is that some customers require that their benders be equipped with palm buttons that must be held during any part of the bending with pinch-point motion.<br><br> | ||

For example, the Allen Bradley 800Z Zero Force Touch Buttons can be installed on the left and right side of control.<br><br> | For example, the Allen Bradley 800Z Zero Force Touch Buttons can be installed on the left and right side of control.<br><br> | ||

| − | + | With manual unloading, there are points in the cycle where it is necessary to grasp the part and open the dies to remove the part from the bender. However, removing hands from the touch buttons to remove the part puts the part into CYCLE HOLD. The commands that examine the RELEASE button and open the dies can be programmed to ignore CYCLE HOLD in order to open the dies in CYCLE HOLD.<br><br> | |

| − | Another benefit of this capability is that commands that wait and watch, illuminate buttons | + | Another benefit of this capability is that commands that wait and watch, illuminate buttons/lights, or set outputs without moving actuators can be working even during CYCLE HOLD. This speeds the process by letting the non-motion commands to continue to run even in CYCLE HOLD. |

</td> | </td> | ||

| Line 53: | Line 53: | ||

<td width=300> | <td width=300> | ||

* This version of CNC Bender has a decreased input check time from 125 ms to 16 ms for faster response time.<br><br> | * This version of CNC Bender has a decreased input check time from 125 ms to 16 ms for faster response time.<br><br> | ||

| − | * This version has repaired logic issue with BEGIN condition inputs that would cause Commands to show incompleted inputs | + | * This version has repaired logic issue with BEGIN condition inputs that would cause Commands to show incompleted inputs when they were completed.<br><br> |

| + | * This version has repaired logic for an issue with edge-detection for inputs.<br><br> | ||

* This version allows the input for Master Power ON to be either a BEGIN or END style input without causing the bender to to never drop out of AUTO mode.<br><br> | * This version allows the input for Master Power ON to be either a BEGIN or END style input without causing the bender to to never drop out of AUTO mode.<br><br> | ||

* The version allows the Safety Relay ON to be either a BEGIN or END style input without a causing the bender to never drop out of AUTO mode.<br><br> | * The version allows the Safety Relay ON to be either a BEGIN or END style input without a causing the bender to never drop out of AUTO mode.<br><br> | ||

Latest revision as of 12:25, 24 July 2013

v12-20130723

|

See CNC Bender Customer Service Page for an update.

NEW: Any Command (COMDEF) can be taught to ignore Cycle Hold

NEW: Any Command (COMDEF) can be taught to ignore Cycle Hold

|

This new feature allows selected COMDEFs to run in the processlist without pausing during CYCLE HOLD. The reason for this new capability is that some customers require that their benders be equipped with palm buttons that must be held during any part of the bending with pinch-point motion. |

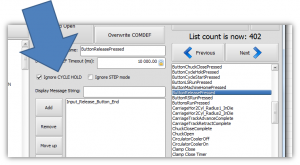

NEW: COMDEF Editor Allows Ignoring Cycle Holds in Commands

NEW: COMDEF Editor Allows Ignoring Cycle Holds in Commands

|

The COMDEF Editor allows setup technicians to indicate which COMDEFs can safely ignore CYCLE HOLDS |

Other Changes

Other Changes

|

Other Pages

- Back to CNC Bender

- Back to CNC Bender Software Updates

- See CNC Bender Customer Service Page for an update.

- See CNC Bender General Information

- See Teach Mode

- See Custom Commands