Difference between revisions of "CNC Bender v12-20120629"

| (12 intermediate revisions by one user not shown) | |||

| Line 13: | Line 13: | ||

</table> | </table> | ||

__NOTOC__ | __NOTOC__ | ||

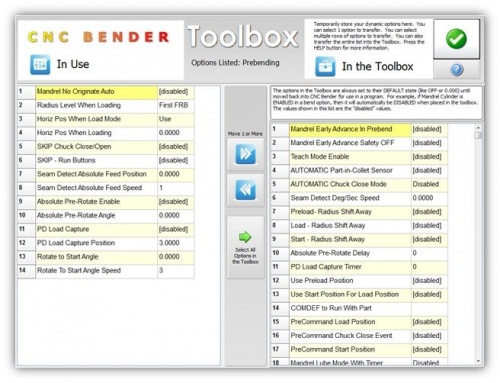

| − | ===[[image:Check.jpg|25px]] Repair | + | ===[[image:Check.jpg|25px]] Repair Processlist Builder Proper Tracking of Option In or Out of Toolbox=== |

| + | [[image:cncbender_toolbox_window.jpg|500px]] | ||

<table cellpadding=10> | <table cellpadding=10> | ||

<tr valign=top> | <tr valign=top> | ||

| Line 20: | Line 21: | ||

By default, dynamic options should be OFF or in their DEFAULT state when in a Toolbox. | By default, dynamic options should be OFF or in their DEFAULT state when in a Toolbox. | ||

<br><br> | <br><br> | ||

| − | However, the CNC Processlist Builder | + | However, the CNC Processlist Builder improperly tracked if an option was inside the toolbox. This sometimes caused hard-to-trace side-effects where an option seemed to be OUT of the Toolbox to Processlist Builder, but was inside the Toolbox in CNC Bender. Unintended effects could be as serious as skipping bends for example. |

<br><br> | <br><br> | ||

This version fixes this issue by allowing both CNC Bender, CNC Processlist Builder and CNC Processor to track if the operator has placed the option in the Toolbox based on which operator station the part is running in. | This version fixes this issue by allowing both CNC Bender, CNC Processlist Builder and CNC Processor to track if the operator has placed the option in the Toolbox based on which operator station the part is running in. | ||

| Line 32: | Line 33: | ||

</table> | </table> | ||

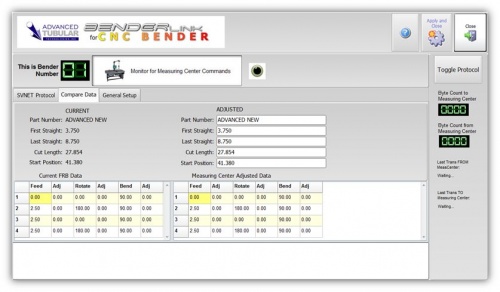

| − | ===[[image:Check.jpg|25px]] Repair | + | ===[[image:Check.jpg|25px]] Repair Mixed up or Garbled SVNET Data from Poor Network Connection=== |

| + | [[image:cncbender_benderlink_screen.jpg|500px]] | ||

| + | <table cellpadding=10> | ||

| + | <tr valign=top> | ||

| + | <td width=400> | ||

| + | The Supravision data incoming to CNC Bender Benderlink could be garbled if Benderlink tried to open and access the data to early - while the file is still growing. Benderlink is now enhanced to watch for the file growth size to stop before opening and taking ownership of the incoming Supravision data. | ||

| + | <br> | ||

| + | </td> | ||

| + | |||

| + | <td width=300> | ||

| + | |||

| + | </td> | ||

| + | |||

| + | </tr> | ||

| + | </table> | ||

| + | |||

| + | ===[[image:Check.jpg|25px]] Enhance Fourth Radius Level Loading=== | ||

<table cellpadding=10> | <table cellpadding=10> | ||

<tr valign=top> | <tr valign=top> | ||

<td width=400> | <td width=400> | ||

| − | The | + | The new Fourth radius level loading feature (added in the previous version) is enhanced and repaired. |

<br> | <br> | ||

</td> | </td> | ||

Latest revision as of 02:13, 30 June 2012

v12-20120629

|

Repair Processlist Builder Proper Tracking of Option In or Out of Toolbox

Repair Processlist Builder Proper Tracking of Option In or Out of Toolbox

|

By default, dynamic options should be OFF or in their DEFAULT state when in a Toolbox.

|

Repair Mixed up or Garbled SVNET Data from Poor Network Connection

Repair Mixed up or Garbled SVNET Data from Poor Network Connection

|

The Supravision data incoming to CNC Bender Benderlink could be garbled if Benderlink tried to open and access the data to early - while the file is still growing. Benderlink is now enhanced to watch for the file growth size to stop before opening and taking ownership of the incoming Supravision data.

|

Enhance Fourth Radius Level Loading

Enhance Fourth Radius Level Loading

|

The new Fourth radius level loading feature (added in the previous version) is enhanced and repaired.

|

Other Pages

- Back to CNC Bender

- Back to CNC Bender Software Updates

- See CNC Bender General Information

- See Teach Mode

- See Custom Commands