Difference between revisions of "CNC Bender v12-20111222"

From ATTWiki

| (36 intermediate revisions by one user not shown) | |||

| Line 13: | Line 13: | ||

</table> | </table> | ||

__NOTOC__ | __NOTOC__ | ||

| − | ===[[image:Check.jpg|25px]] NEW - PRESSURE DIE | + | ===[[image:Check.jpg|25px]] NEW - Logic for Servo-controlled PRESSURE DIE Motion Installed === |

| − | + | ||

| − | + | ||

| + | [[image:pressuredie_bending.jpg|250px]] | ||

| + | [[image:pd_servo_encoder.jpg|250px]] | ||

<table cellpadding=10> | <table cellpadding=10> | ||

<tr valign=top> | <tr valign=top> | ||

<td width=400> | <td width=400> | ||

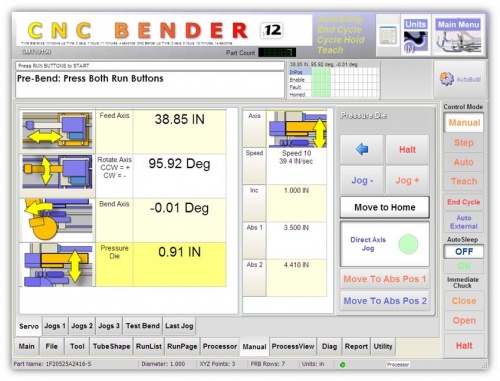

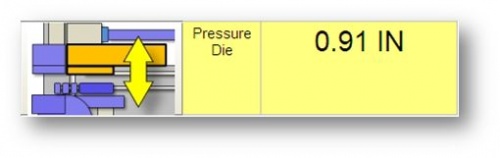

| − | * | + | * Servo-controlled pressure die positioning is more accurate than standard output control.<br><br> |

| − | * This feature is especially useful for extreme accuracy during part capture. | + | * This feature is especially useful for extreme accuracy during part capture. Parts can be accurately captured by the pressure die during PREBEND (Load), BENDING, and POSTBENDING (Unloading).<br><br> |

| − | + | [[image:manual_page_PD_axis.jpg|500px]] | |

| − | + | [[image:manual_page_PD_axis_closeup.jpg|500px]]<br> | |

</td> | </td> | ||

<td width=300> | <td width=300> | ||

| + | |||

| + | |||

</td> | </td> | ||

</tr> | </tr> | ||

</table> | </table> | ||

| − | |||

| − | ===[[image:Check.jpg|25px]] NEW - | + | ===[[image:Check.jpg|25px]] NEW - Options for PD Servo Motion === |

| − | |||

<table cellpadding=10> | <table cellpadding=10> | ||

| + | |||

| + | |||

<tr valign=top> | <tr valign=top> | ||

<td width=400> | <td width=400> | ||

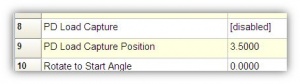

| − | + | '''PreBend Options: PD Load Capture Position''' | |

| − | + | * This feature allows you to move the pressure die to a position close to the bend die for load-capture. | |

| − | * This | + | |

</td> | </td> | ||

| − | |||

<td width=300> | <td width=300> | ||

| + | [[image:pd_servo_load_capture.jpg|300px]] | ||

</td> | </td> | ||

| − | |||

| − | |||

</tr> | </tr> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

<tr valign=top> | <tr valign=top> | ||

<td width=400> | <td width=400> | ||

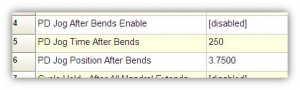

| − | + | '''Overall Options: PD Jog Position After Bends''' | |

| − | * This | + | * This feature allows you to open the pressure die slightly after a bend to relieve pressure before a mandrel pull. |

</td> | </td> | ||

| − | |||

<td width=300> | <td width=300> | ||

| + | [[image:pd_servo_jog_position_after_bends.jpg|300px]] | ||

</td> | </td> | ||

| − | |||

| − | |||

</tr> | </tr> | ||

| − | |||

| − | |||

| − | |||

| − | |||

<tr valign=top> | <tr valign=top> | ||

<td width=400> | <td width=400> | ||

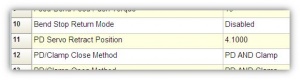

| − | + | '''Bending Options: PD Servo Retract Position''' | |

| − | + | * This feature allows you to partially retract the pressure die during Multi-Bending and immediately after a bend. | |

| − | * | + | |

| − | + | ||

</td> | </td> | ||

| − | |||

<td width=300> | <td width=300> | ||

| + | [[image:pd_servo_retract_postion.jpg|300px]] | ||

</td> | </td> | ||

| + | </tr> | ||

| + | <tr valign=top> | ||

| + | <td width=400> | ||

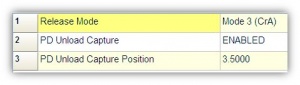

| + | '''PostBending Options: PD Unload Capture Position''' | ||

| + | * This feature allows you to partially retract the pressure die immediately after the last bend for unloading. | ||

| + | </td> | ||

| + | <td width=300> | ||

| + | [[image:pd_servo_unload_capture.jpg|300px]] | ||

| + | </td> | ||

</tr> | </tr> | ||

| + | |||

| + | |||

| + | |||

</table> | </table> | ||

| − | |||

===[[image:Check.jpg|25px]] Other === | ===[[image:Check.jpg|25px]] Other === | ||

| Line 91: | Line 88: | ||

<tr valign=top> | <tr valign=top> | ||

<td width=400> | <td width=400> | ||

| − | * | + | * A new Low Level PD Mode option allows the Pressure Die to be treated as a standard output actuator or a servo axis.<br><br> |

| − | * | + | |

| − | * | + | * A new Low Level PD Servo Fixed Close Position option is added that controls the single fixed position of a closed pressure die when the PD Mode is set to Servo Fixed Position.<br><br> |

| − | ** | + | |

| − | ** | + | * Pressure Die COMDEFs were added: |

| − | ** | + | **PD Servo Absolute |

| + | **PD Servo Incremental Positive | ||

| + | **PD Servo And Clamp Output And PDA Output Home | ||

| + | **PD Servo Absolute And PDA Output Home | ||

| + | **PD Servo Absolute And Clamp Output Home | ||

| + | **PD Servo Find Home | ||

| + | **PD Servo Reset Position | ||

| + | **PD Servo Absolute and PDA Servo Absolute | ||

| + | **PD Servo Absolute And PDA Output Home<br><br> | ||

| − | * | + | * COMDEF Names Changed |

| − | ** | + | ** PressureDieBoostToHome to "PD Output PDA Output Home" |

| − | ** | + | ** Pressure Die and PDA Motion Home to "PD Output and PDA Servo Home"<br><br> |

* New help files were added: | * New help files were added: | ||

| − | ** | + | ** PDMode.rtf |

| − | ** | + | ** PDServoFixedClosedPosition.rtf |

| − | ** | + | ** PDServoLoadCapturePosition.rtf |

| − | ** | + | ** PDServoRetractPosition.rtf |

| + | ** PDServoUnloadCapturePosition.rtf | ||

| − | |||

| − | |||

</td> | </td> | ||

Latest revision as of 04:45, 24 December 2011

v12-20111222

|

NEW - Logic for Servo-controlled PRESSURE DIE Motion Installed

NEW - Logic for Servo-controlled PRESSURE DIE Motion Installed

|

|

NEW - Options for PD Servo Motion

NEW - Options for PD Servo Motion

|

PreBend Options: PD Load Capture Position

|

|

|

Overall Options: PD Jog Position After Bends

|

|

|

Bending Options: PD Servo Retract Position

|

|

|

PostBending Options: PD Unload Capture Position

|

Other

Other

|

Other Pages

- Back to CNC Bender

- Back to CNC Bender Software Updates

- See CNC Bender General Information

- See Teach Mode

- See Custom Commands