Difference between revisions of "CNC Bender v12-20111222"

From ATTWiki

| Line 35: | Line 35: | ||

<table cellpadding=10> | <table cellpadding=10> | ||

| + | |||

<tr valign=top> | <tr valign=top> | ||

<td width=400> | <td width=400> | ||

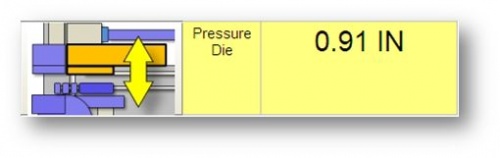

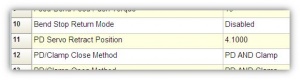

Bending Options: PD Servo Retract Position | Bending Options: PD Servo Retract Position | ||

| + | * This feature allows you to partially retract the pressure die during Multi-Bending and immediately after a bend. | ||

</td> | </td> | ||

<td width=300> | <td width=300> | ||

| Line 43: | Line 45: | ||

</td> | </td> | ||

</tr> | </tr> | ||

| + | |||

| + | <tr valign=top> | ||

| + | <td width=400> | ||

| + | Overall Options: PD Jog Position After Bends | ||

| + | * This feature allows you to open the pressure die slightly after a bend to relieve pressure before a mandrel pull. | ||

| + | </td> | ||

| + | <td width=300> | ||

| + | [[image:pd_servo_jog_postion_after_bends.jpg|300px]] | ||

| + | </td> | ||

| + | </tr> | ||

| + | |||

</table> | </table> | ||

Revision as of 04:08, 23 December 2011

v12-20111222

|

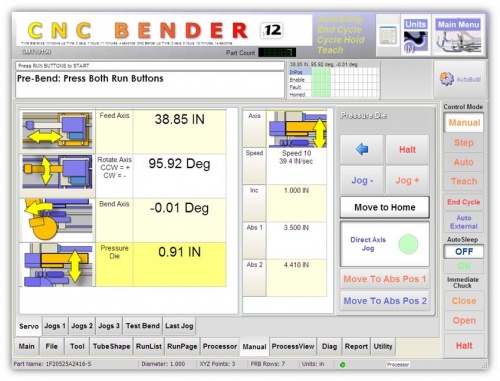

NEW - Servo-controlled PRESSURE DIE Motion

NEW - Servo-controlled PRESSURE DIE Motion

|

NEW - Options for PD Servo Motion

NEW - Options for PD Servo Motion

|

Bending Options: PD Servo Retract Position

|

|

|

Overall Options: PD Jog Position After Bends

|

NEW - CNC Processor Builds a Part Name File in the LOGS Folder

NEW - CNC Processor Builds a Part Name File in the LOGS Folder

|

ENHANCED - Seam Find Detection Logic

ENHANCED - Seam Find Detection Logic

|

Other

Other

|

Other Pages

- Back to CNC Bender

- Back to CNC Bender Software Updates

- See CNC Bender General Information

- See Teach Mode

- See Custom Commands