Difference between revisions of "CNC Bender v12-20111215"

From ATTWiki

| (30 intermediate revisions by one user not shown) | |||

| Line 13: | Line 13: | ||

</table> | </table> | ||

__NOTOC__ | __NOTOC__ | ||

| − | ===[[image:Check.jpg|25px]] NEW - Send Part Number to Robots in Auto Mode === | + | ===[[image:Check.jpg|25px]] NEW - CNC Processor Can Send Part Number to Robots in Auto Mode === |

<table cellpadding=10> | <table cellpadding=10> | ||

<tr valign=top> | <tr valign=top> | ||

<td width=400> | <td width=400> | ||

| − | * CNC | + | * CNC Processor can load and run an external program at the moment it changes part numbers in Auto mode.<br><br> |

| − | * A new option is in Low Level options list that is called "External File To Run When Part Changes In Processor". | + | * A new option is in CNC Bender Low Level options list that is called "External File To Run When Part Changes In Processor".<br><br> |

| + | * To use this feature, enter the name of the external executable file and CNC Processor will run the program any time a new part number is run in Auto mode. (See the next item for the first program to be called by this feature.)<br><br> | ||

</td> | </td> | ||

<td width=300> | <td width=300> | ||

| + | [[image:fanuc_robot_710i.jpg|200px]] | ||

</td> | </td> | ||

| Line 36: | Line 38: | ||

<td width=400> | <td width=400> | ||

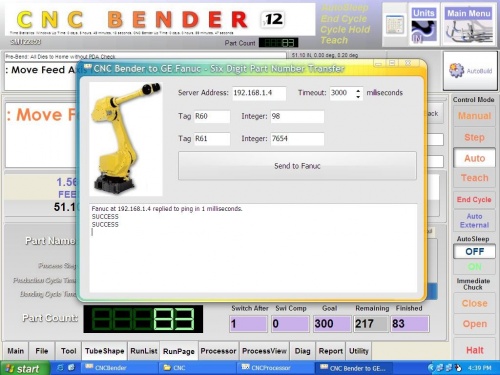

* A new communications program can be run by the new feature described above.<br><br> | * A new communications program can be run by the new feature described above.<br><br> | ||

| − | * The program loads into memory, loads the current part from the part log, sends the data to the Fanuc robot, then closes. | + | * The program loads into memory, loads the current part from the part log, sends the data to the Fanuc robot, then closes.<br><br> |

| + | * This method of sending data allows any software developer to create a program that can send data to other computers through networks whenever CNC Processor changes parts. | ||

</td> | </td> | ||

| Line 46: | Line 49: | ||

</table> | </table> | ||

| − | ===[[image:Check.jpg|25px]] | + | |

| + | ===[[image:Check.jpg|25px]] NEW - CNC Processor Builds a Part Name File in the LOGS Folder === | ||

<table cellpadding=10> | <table cellpadding=10> | ||

<tr valign=top> | <tr valign=top> | ||

<td width=400> | <td width=400> | ||

| − | * | + | * When CNC Processor encounters a PART NAME command in the processor list, it now saves the part name to the a ''"cncprocessor_partname.log"'' file in the c:\cnc\logs folder.<br><br> |

| − | * | + | * This file contains only the part number, and can be accessed by any external process to allow the external process to know which part is currently running. |

</td> | </td> | ||

| Line 62: | Line 66: | ||

</table> | </table> | ||

| − | ===[[image:Check.jpg|25px]] | + | ===[[image:Check.jpg|25px]] ENHANCED - Seam Find Detection Logic === |

| − | + | [[image:holedetect1.jpg|400px]] | |

<table cellpadding=10> | <table cellpadding=10> | ||

<tr valign=top> | <tr valign=top> | ||

<td width=400> | <td width=400> | ||

| − | * | + | * Several new PREBEND options allow for better control of the seam detect option in the Rotate Axis.<br><br> |

| + | * Added new COMDEF to set the seam detect rotate axis jog speed: ''Set Rotate Jog Speed.comdef''<br><br> | ||

| + | * Added new HELP files to explain the new PREBEND seam detect options.<br><br> | ||

| + | * Added Sensor advance and retract COMDEFs (Seam Sensor | ||

</td> | </td> | ||

<td width=300> | <td width=300> | ||

</td> | </td> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

</tr> | </tr> | ||

</table> | </table> | ||

| + | [[image:holedetect2.jpg|400px]] | ||

| − | ===[[image:Check.jpg|25px]] | + | ===[[image:Check.jpg|25px]] Other === |

<table cellpadding=10> | <table cellpadding=10> | ||

<tr valign=top> | <tr valign=top> | ||

<td width=400> | <td width=400> | ||

| − | * | + | * Importing older part files now brings the Tool data into memory also.<br><br> |

| − | < | + | * Older file imports no longer reset the bender name.<br><br> |

| + | * New COMDEFS were added: | ||

| + | **Set Rotate Jog Speed.comdef | ||

| + | **Seam Sensor Retract.comdef | ||

| + | **Seam Sensor Advance.comdef<br><br> | ||

| − | + | * New CIO objects were added: | |

| − | + | **Output_SeamDetectSensor_Advance | |

| − | < | + | **Output_SeamDetectSensor_Retract<br><br> |

| − | < | + | |

| + | * New help files were added: | ||

| + | ** Option_PrebendSeamDetectDegreesPerSecond.rtf | ||

| + | ** Option_PrebendSeamDetectFeedAbsoluteSpeed.rtf | ||

| + | ** Option_PrebendSeamDetectFeedAbsolutePosition.rtf | ||

| + | ** ExternalFileToRunWhenPartChangesInProcessor.rtf<br><br> | ||

| − | + | * This help file was updated: | |

| + | ** Option_PrebendSeamDetectMode.rtf | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

</td> | </td> | ||

Latest revision as of 15:13, 19 December 2011

v12-20111215

|

NEW - CNC Processor Can Send Part Number to Robots in Auto Mode

NEW - CNC Processor Can Send Part Number to Robots in Auto Mode

|

NEW - Communication of 6 Digit Integer Part Number with GE-Fanuc Robot

NEW - Communication of 6 Digit Integer Part Number with GE-Fanuc Robot

|

NEW - CNC Processor Builds a Part Name File in the LOGS Folder

NEW - CNC Processor Builds a Part Name File in the LOGS Folder

|

ENHANCED - Seam Find Detection Logic

ENHANCED - Seam Find Detection Logic

|

Other

Other

|

Other Pages

- Back to CNC Bender

- Back to CNC Bender Software Updates

- See CNC Bender General Information

- See Teach Mode

- See Custom Commands