CNC Bender v12-20100903

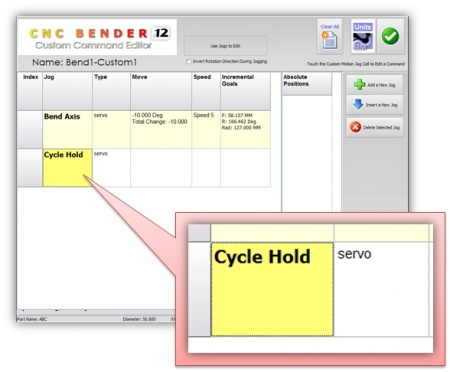

NEW - CYCLE HOLD in Custom Commands and in TEACH Mode

NEW - CYCLE HOLD in Custom Commands and in TEACH Mode

|

Now CYCLE HOLD anywhere inside a CUSTOM COMMAND either manually entered or taught during TEACH MODE. |

|

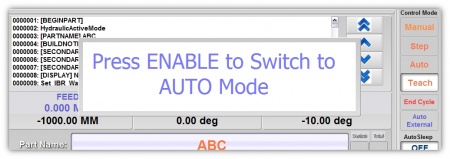

ENHANCED - ENABLE Button for STEP and AUTO Modes

ENHANCED - ENABLE Button for STEP and AUTO Modes

|

The "REQUIRE ENABLE BUTTON" feature, when active, now also monitors for a switch to AUTO or STEP modes from MANUAL mode |

|

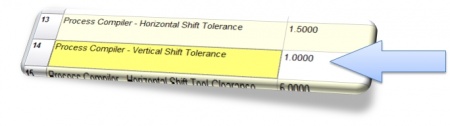

ENHANCED - Vertical Head Shift Tolerance Added

ENHANCED - Vertical Head Shift Tolerance Added

|

The vertical head shift tolerance allows us to skip motion when an axis is close enough to the final position. |

|

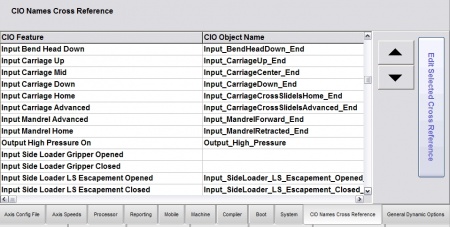

ENHANCED - Added CNC Processor Automatic High Pressure Handling

ENHANCED - Added CNC Processor Automatic High Pressure Handling

|

CNC Processor now uses the CIO Name Cross Reference in the Low Level menu to automatically set the high pressure under these two special circumstances:

|

|

ENHANCED - More Features for Soft EOT for Each Axis - JOG Speeds Ramp Down

ENHANCED - More Features for Soft EOT for Each Axis - JOG Speeds Ramp Down

|

During JOGGING - CNC Processor can check for EOT (end of travel) of an axis before it arrives at the true FAULT EOT. This gives the axis a chance to stop jogging before it arrives at a FAULT position or emergency switch.

|

The following section is extracted from an AXIS configuration file soft EOT section:

Example of what to add in each AXIS in the main.axislist file. The value shown here are typical of the BEND axis: Enable EOT=1 Low EOT=0.75 High EOT=191 Jog Speed=10 Jog Speed Approach EOT=0.5 Approach EOT Range=5 |

| In the example given here, when the bend arm is more than 5 degrees from the soft EOT, it travels at 10 degrees per second. However, when it reaches within 5 degrees of either EOT, then the speed drops to 0.5 degrees per second. |

Other Pages

- Back to CNC Bender

- Back to CNC Bender Software Updates

- See CNC Bender General Information

- See Teach Mode

- See Custom Commands