CNC Bender v12-20100827

ENHANCED - Run Buttons Check for CLEAR to Run Cycle

ENHANCED - Run Buttons Check for CLEAR to Run Cycle

|

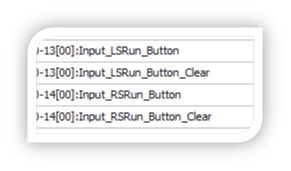

The processlist builder now uses a "Wait For Run Buttons Clear" command to test for clear run buttons before continuing the cycle to check for a Run Buttons press. |

[BIGDISPLAY] Waiting for RUN BUTTONS CLEAR [DISPLAY] Next Step: (Pre-Bend) Wait for the run buttons to CLEAR Wait For Run Buttons Clear |

ENHANCED - Run Buttons Advance a STEP In STEP Mode only when CLEAR

ENHANCED - Run Buttons Advance a STEP In STEP Mode only when CLEAR

|

Now the release of the run buttons is what triggers CNC Bender to advanced to the next step in step mode. |

|

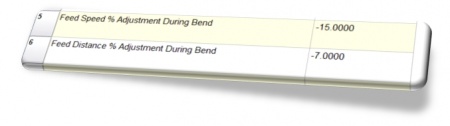

NEW - Feed Distance Percent Adjust in each BEND Option

NEW - Feed Distance Percent Adjust in each BEND Option

|

Now each bend option has its own Feed Distance % Adjust value. |

|

NEW - Loop Priority Item in CNCProcessor.cfg File

NEW - Loop Priority Item in CNCProcessor.cfg File

|

Two new entries allow you to control the looping priority of each loop in CNC Processor 0 = Idle |

[Loop] Main Loop Interval=0.05 Main Loop Priority=4 Background Read Servo Loop Interval=0.05 Background Read Servo Loop Priority=4 |

Other Pages

- Back to CNC Bender

- Back to CNC Bender Software Updates

- See CNC Bender General Information

- See Teach Mode

- See Custom Commands