Difference between revisions of "CNC Bender v12-20100827"

| (19 intermediate revisions by one user not shown) | |||

| Line 9: | Line 9: | ||

</table> | </table> | ||

| − | + | __TOC__ | |

| Line 16: | Line 16: | ||

<tr valign=top> | <tr valign=top> | ||

<td width=200> | <td width=200> | ||

| + | |||

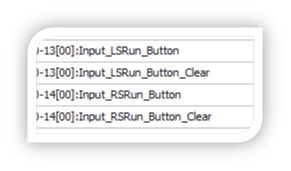

The processlist builder now uses a "Wait For Run Buttons Clear" command to test for clear run buttons before continuing the cycle to check for a Run Buttons press.<br><br> | The processlist builder now uses a "Wait For Run Buttons Clear" command to test for clear run buttons before continuing the cycle to check for a Run Buttons press.<br><br> | ||

This protects against the run buttons being permanently enabled through a failure and causing the machine to run without the buttons being pressed.<br><br> | This protects against the run buttons being permanently enabled through a failure and causing the machine to run without the buttons being pressed.<br><br> | ||

| Line 26: | Line 27: | ||

Wait For Run Buttons Clear | Wait For Run Buttons Clear | ||

</pre> | </pre> | ||

| + | <br> | ||

| + | [[image:runbutton.jpg|150px]]<br> | ||

</td> | </td> | ||

</tr> | </tr> | ||

| Line 37: | Line 40: | ||

</tr> | </tr> | ||

</table> | </table> | ||

| − | |||

===[[image:Check.jpg|25px]] ENHANCED - Run Buttons Advance a STEP In STEP Mode only when CLEAR === | ===[[image:Check.jpg|25px]] ENHANCED - Run Buttons Advance a STEP In STEP Mode only when CLEAR === | ||

| Line 61: | Line 63: | ||

</tr> | </tr> | ||

</table> | </table> | ||

| − | |||

| − | + | ===[[image:Check.jpg|25px]] NEW - Feed Distance Percent Adjust in each BEND Option === | |

| − | + | <table cellpadding=10> | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | ===[[image:Check.jpg|25px]] NEW - | + | |

| − | <table> | + | |

<tr valign=top> | <tr valign=top> | ||

<td width=200> | <td width=200> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

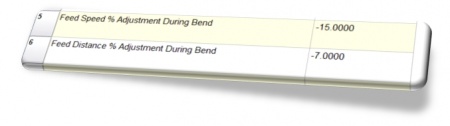

| + | Now each bend option has its own Feed Distance % Adjust value.<br><br> | ||

| + | The value is combined with the values already present in the Tool page.<br><br> | ||

| + | For example, the adjustment for rad level 1 may be -3%. The adjustment for a bend can add or take away from the tool page value. Enter -7% in bend 1 for rad level 1 to make the total of -10% for that bend alone.<br><br> | ||

| + | This allows you to adjust the percentage for speed and distance on a per-bend basis. | ||

</td> | </td> | ||

<td> | <td> | ||

| − | [[image: | + | [[image:feeddistancepercentadjustment_bendoption.jpg|450px]]<br> |

</td> | </td> | ||

</tr> | </tr> | ||

| Line 89: | Line 81: | ||

<tr valign=top> | <tr valign=top> | ||

<td width=300> | <td width=300> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

</td> | </td> | ||

<td> | <td> | ||

| − | |||

</td> | </td> | ||

</tr> | </tr> | ||

</table> | </table> | ||

| − | + | ===[[image:Check.jpg|25px]] NEW - Loop Priority Item in CNCProcessor.cfg File === | |

| − | + | <table cellpadding=10> | |

| − | ===[[image:Check.jpg|25px]] NEW - | + | |

| − | <table> | + | |

<tr valign=top> | <tr valign=top> | ||

<td width=200> | <td width=200> | ||

| − | |||

| − | + | Two new entries allow you to control the looping priority of each loop in CNC Processor<br><br> | |

| − | + | The values are 0, 1, 2, 3, or 4.<br><br> | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | <br> | + | 0 = Idle<br> |

| − | <br> | + | 1 = Lowest<br> |

| + | 2 = Normal<br> | ||

| + | 3 = Highest<br> | ||

| + | 4 = Time Critical<br><br> | ||

</td> | </td> | ||

<td> | <td> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

<pre> | <pre> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

[Loop] | [Loop] | ||

| − | Main Loop Interval=0. | + | Main Loop Interval=0.05 |

| − | Background Read Servo Loop Interval=0. | + | Main Loop Priority=4 |

| + | Background Read Servo Loop Interval=0.05 | ||

| + | Background Read Servo Loop Priority=4 | ||

</pre> | </pre> | ||

| − | |||

</td> | </td> | ||

</tr> | </tr> | ||

| Line 191: | Line 115: | ||

<tr valign=top> | <tr valign=top> | ||

<td width=300> | <td width=300> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

</td> | </td> | ||

<td> | <td> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

</td> | </td> | ||

</tr> | </tr> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

</table> | </table> | ||

Latest revision as of 23:50, 3 September 2010

Contents |

ENHANCED - Run Buttons Check for CLEAR to Run Cycle

ENHANCED - Run Buttons Check for CLEAR to Run Cycle

|

The processlist builder now uses a "Wait For Run Buttons Clear" command to test for clear run buttons before continuing the cycle to check for a Run Buttons press. |

[BIGDISPLAY] Waiting for RUN BUTTONS CLEAR [DISPLAY] Next Step: (Pre-Bend) Wait for the run buttons to CLEAR Wait For Run Buttons Clear |

ENHANCED - Run Buttons Advance a STEP In STEP Mode only when CLEAR

ENHANCED - Run Buttons Advance a STEP In STEP Mode only when CLEAR

|

Now the release of the run buttons is what triggers CNC Bender to advanced to the next step in step mode. |

|

NEW - Feed Distance Percent Adjust in each BEND Option

NEW - Feed Distance Percent Adjust in each BEND Option

|

Now each bend option has its own Feed Distance % Adjust value. |

|

NEW - Loop Priority Item in CNCProcessor.cfg File

NEW - Loop Priority Item in CNCProcessor.cfg File

|

Two new entries allow you to control the looping priority of each loop in CNC Processor 0 = Idle |

[Loop] Main Loop Interval=0.05 Main Loop Priority=4 Background Read Servo Loop Interval=0.05 Background Read Servo Loop Priority=4 |

Other Pages

- Back to CNC Bender

- Back to CNC Bender Software Updates

- See CNC Bender General Information

- See Teach Mode

- See Custom Commands