Difference between revisions of "CNC Bender v12-20100827"

| Line 77: | Line 77: | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

===[[image:Check.jpg|25px]] NEW - Quiet EOT for Each Axis === | ===[[image:Check.jpg|25px]] NEW - Quiet EOT for Each Axis === | ||

Revision as of 19:49, 26 August 2010

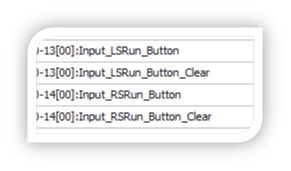

ENHANCED - Run Buttons Check for CLEAR to Run Cycle

ENHANCED - Run Buttons Check for CLEAR to Run Cycle

|

The processlist builder now uses a "Wait For Run Buttons Clear" command to test for clear run buttons before continuing the cycle to check for a Run Buttons press. |

[BIGDISPLAY] Waiting for RUN BUTTONS CLEAR [DISPLAY] Next Step: (Pre-Bend) Wait for the run buttons to CLEAR Wait For Run Buttons Clear |

ENHANCED - Run Buttons Advance a STEP In STEP Mode only when CLEAR

ENHANCED - Run Buttons Advance a STEP In STEP Mode only when CLEAR

|

Now the release of the run buttons is what triggers CNC Bender to advanced to the next step in step mode. |

|

NEW - Quiet EOT for Each Axis

NEW - Quiet EOT for Each Axis

|

During JOGGING - CNC Processor can check for EOT (end of travel) of an axis before it arrives at the true FAULT EOT. This gives the axis a chance to stop jogging before it arrives at a FAULT position or emergency switch.

|

The following additions have been made to the AXIS configuration file:

Example of what to add in each AXIS in the main.axislist file. The value shown here are typical of the FEED axis: Enable EOT=1 Low EOT=0 High EOT=3160 |

|

When the axis arrives at the programmed EOT, a Big Message (see above) displays on the screen that announces that the axis has arrived at the axis EOT - and CNC Processor stops the axis motion. |

Other Pages

- Back to CNC Bender

- Back to CNC Bender Software Updates

- See CNC Bender General Information

- See Teach Mode

- See Custom Commands