CNC Bender v11-20091104

From ATTWiki

The changes in this version are designed to make CNC Bender run faster. On a 2 bend part with a side-loader, these optimizations combined trimmed 4 or more seconds off of every bend cycle.

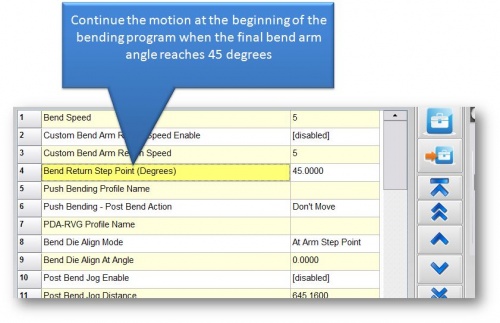

NEW - Final Bend Simultaneous Motion

NEW - Final Bend Simultaneous Motion

|

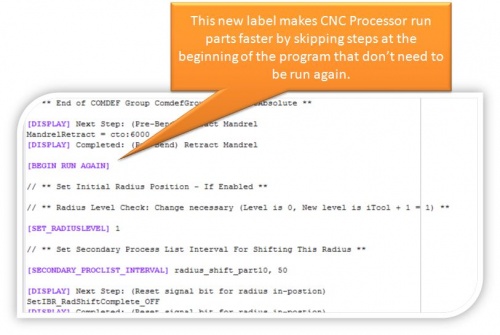

NEW - New Optimization in Processor - Makes Bender Run Faster

NEW - New Optimization in Processor - Makes Bender Run Faster

|

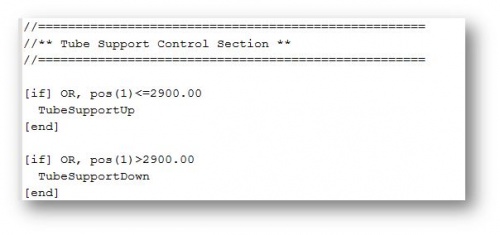

NEW - Second Constant Run List Designed for HIGH SPEED

NEW - Second Constant Run List Designed for HIGH SPEED

|

Other Pages

- Back to CNC Bender

- Back to CNC Bender Software Updates

- See CNC Bender General Information

- See Absolute Rotate

- See Absolute Rotate Offset Position

- See Final Feed Clearance

- See Mandrel Retract

- See Mandrel Retract Part Release