Difference between revisions of "CNC Bender v11-20091104"

From ATTWiki

| (35 intermediate revisions by one user not shown) | |||

| Line 1: | Line 1: | ||

| + | <table> | ||

| + | <tr> | ||

| + | <td width=300> | ||

[[image:Cncbender_logo_pushbending.png]] | [[image:Cncbender_logo_pushbending.png]] | ||

| − | + | <br> | |

| − | + | <table> | |

| + | <tr> | ||

| + | <td> | ||

| + | Type of Upgrade: '''FASTER BENDING''' | ||

| + | </td> | ||

| + | <td> | ||

| + | The changes in this version are designed to make CNC Bender run faster. On a 2 part with a side-loader, these optimizations combined trimmed 4 or more seconds off of every bend cycle. | ||

| + | </td> | ||

| + | </tr> | ||

| + | </table> | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:Operatorstation_model.jpg]] | ||

| + | </td> | ||

| + | </tr> | ||

| + | </table> | ||

| + | __NOTOC__ | ||

| − | |||

| + | ===[[image:Check.jpg|25px]] NEW - Final Bend Simultaneous Motion=== | ||

<table> | <table> | ||

<tr> | <tr> | ||

<td width=300> | <td width=300> | ||

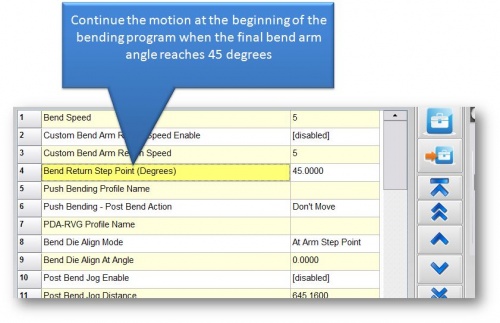

| − | * The final bend arm return motion now allows | + | * The final bend arm return motion now allows the process list that follows to begin even if the bend arm is still returning home.<br><br> |

* The Bend Return Step Point value in the last row controls when the final bend arm return will release the processlist to move back to the beginning of the program. | * The Bend Return Step Point value in the last row controls when the final bend arm return will release the processlist to move back to the beginning of the program. | ||

| − | + | <br> | |

| + | [[image:bendarm_blur_vb150.jpg|300px]] | ||

</td> | </td> | ||

| Line 24: | Line 44: | ||

<br><br> | <br><br> | ||

| − | |||

===[[image:Check.jpg|25px]] NEW - New Optimization in Processor - Makes Bender Run Faster=== | ===[[image:Check.jpg|25px]] NEW - New Optimization in Processor - Makes Bender Run Faster=== | ||

| Line 31: | Line 50: | ||

<tr> | <tr> | ||

<td width=300> | <td width=300> | ||

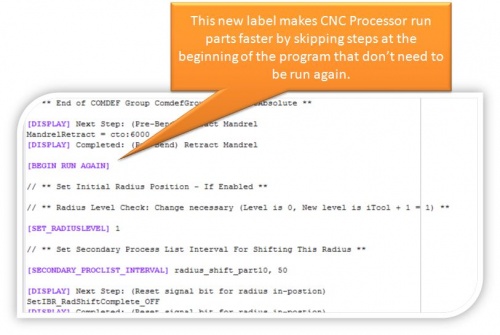

| − | * | + | * '''This is an important change that trims seconds of each cycle.''' |

| − | + | * Every part process list begins with an initialization section that can easily be 50 lines of commands. Running through these commands for the same part repeatedly when starting the next part cycle wastes time. <br><br> | |

| + | |||

| + | * So the CNC Processlist Builder now inserts a new [BEGIN RUN AGAIN] label placed in the middle of each part's process list to trim off processing time by showing CNC Processor where to start when the same part is run the second time and greater.<br><br> | ||

| + | |||

</td> | </td> | ||

| Line 44: | Line 66: | ||

<br><br> | <br><br> | ||

| − | ===[[image:Check.jpg|25px]] NEW - | + | ===[[image:Check.jpg|25px]] NEW - Second Constant Run List Designed for HIGH SPEED OPERATIONS === |

<table cellpadding=5> | <table cellpadding=5> | ||

| Line 50: | Line 72: | ||

<td width=300> | <td width=300> | ||

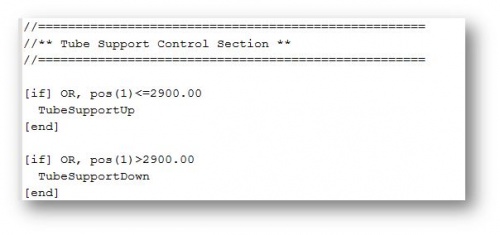

* USe the new high-speed constant run list for processes that should run all the time and get high attention.<br><br> | * USe the new high-speed constant run list for processes that should run all the time and get high attention.<br><br> | ||

| − | * Control the interval of how often the list runs in the Processor tab in the Low Level menu. | + | * Control the interval of how often the list runs in the Processor tab in the Low Level menu.<br><br> |

| + | |||

| + | * The list file is separate from the ConstantRun processlist. The name is '''"ConstantRunHS.processlist"'''<br><br> | ||

| + | |||

| + | * Put tube-support control in this list to make it more responsive to fast moving Feed axes. | ||

| + | |||

</td> | </td> | ||

| Line 59: | Line 86: | ||

</table> | </table> | ||

| − | + | <br> | |

| − | + | <br> | |

=Other Pages= | =Other Pages= | ||

Latest revision as of 23:09, 4 November 2009

|

NEW - Final Bend Simultaneous Motion

NEW - Final Bend Simultaneous Motion

|

NEW - New Optimization in Processor - Makes Bender Run Faster

NEW - New Optimization in Processor - Makes Bender Run Faster

|

NEW - Second Constant Run List Designed for HIGH SPEED OPERATIONS

NEW - Second Constant Run List Designed for HIGH SPEED OPERATIONS

|

Other Pages

- Back to CNC Bender

- Back to CNC Bender Software Updates

- See CNC Bender General Information

- See Absolute Rotate

- See Absolute Rotate Offset Position

- See Final Feed Clearance

- See Mandrel Retract

- See Mandrel Retract Part Release