CNC Bender v11-20090515

NEW - Speed Edit Makes Editing Faster

NEW - Speed Edit Makes Editing Faster

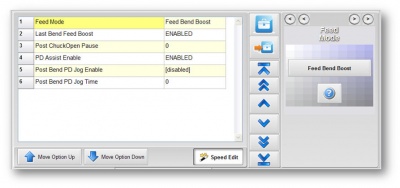

Speed edit makes editing faster because you only have to press an option once to begin editing. The Speed Edit button is a button that is activated by pressing the button down.

NEW - Infinitely Variable Radius in Push Bend

NEW - Infinitely Variable Radius in Push Bend

We've added infinitely variable radius to our push bend capability

Change the radius of a Push Bend as the Feed is moving forward.

- Move the feed forward and the bend arm back in order create an larger radius as the bend progresses.

- Move the feed forward and the bend arm forward to create a smaller radius as the bend progresses.

- Twist the rotation axis as the carriage moves forward to create a spiral or helix inside the variable radius part.

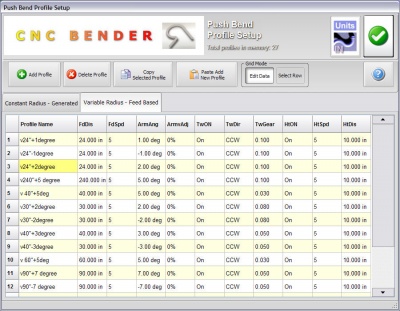

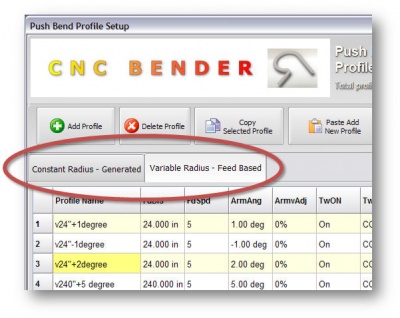

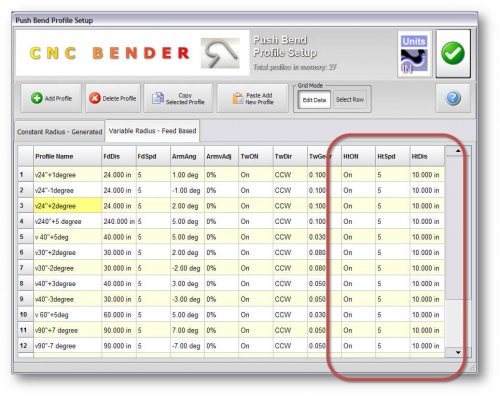

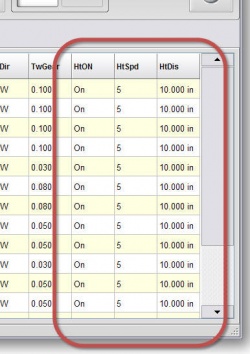

To control this new feature, a tab is added to the Push Bend Profile Setup menu: "Variable Radius - Feed Based"

Notat that the FEED DISTANCE value is placed first after the profile name because it is now the controller of the command. The feed will move forward the programmed distance. Example:

- Feed: 240 inches - The carriage will move 240" for this variable radius push bend.

- Arm Angle: +5 degrees - The arm will move forward 5 degrees over 240" of push bend

- Twist Ratio: 0.1 - Rotate clockwise with a gear ratio of 0.1 degrees per millimeter of carriage motion

NEW - Hitch Feed Inside Push Bend

NEW - Hitch Feed Inside Push Bend

There is now hitch feeding inside Push Bending as a separate function compared to hitch feeding outside push bends.

NEW - Interconnect Multiple Push Bends

NEW - Interconnect Multiple Push Bends

Now you can interconnect push bends without opening the dies between push bend profiles.

- Program a part with multiple rows

- Put one push bend profile on each row

- In the Bend Options for each push bend, set the new Post Push Bending Action to "Don't Move"

This last setting will prevent the dies from opening and prevent the FEED from moving between rows.

NEW - Separate COPY and PASTE Buttons in Push Bend Profile Setup

NEW - Separate COPY and PASTE Buttons in Push Bend Profile Setup

This new feature allows you to select a FIXED radius push bend, copy it to the clipboard, then select another push bend type, then paste to that new push bend type.

NEW - CNC Bender Checks for DUPLICATE names in the Push Bend Profile setup

NEW - CNC Bender Checks for DUPLICATE names in the Push Bend Profile setup

Push Bend Profiles are extracted from the list of profiles based on the profile NAME. With duplicate profile names, only the first profile with the name would be used. This warning will help prevent editing a profile row that will never have effect.

NEW - PASTE Checks for a DUPLICATE NAME and CHANGES it if necessary

NEW - PASTE Checks for a DUPLICATE NAME and CHANGES it if necessary

Since duplicate profile names will exist when copying and pasting occurs, the feature automatically changes the profile names by adding asterisk characters to the beginning of the profile name until there are no duplicates of that name.

NEW - FRB Row Paste (from Memory) - CNC Bender Asks for Overwrite, Insert After, or Append

NEW - FRB Row Paste (from Memory) - CNC Bender Asks for Overwrite, Insert After, or Append

Now when your PASTE an FRB row, CNC Bender will ask how you want to paste the row.

- Overwrite the selected row

- Insert after the selected row

- Add to the end of the bend rows

Use this command with the COPY FRB command to quickly duplicate rows in the FRB editor.

Other Pages

- Back to CNC Bender

- Back to CNC Bender Software Updates

- Read about Push Bending

- Read about Push Bend Profile Tables