Difference between revisions of "CNC Bender v11-20090126"

(→WARNING: Be Careful to Set Proper Torque Limits) |

|||

| (16 intermediate revisions by one user not shown) | |||

| Line 5: | Line 5: | ||

| + | ===[[image:Check.jpg|25px]] NEW - SAVE and OPEN Tool Set Files from the Tool Page === | ||

| + | |||

| + | The tool page now has open and save buttons for TOOL SET FILE management in CNC Bender. | ||

| + | <br><br> | ||

| + | |||

| + | [[image:cncbender_new_loadsave_file_toolpage.jpg|600px]] | ||

| + | <br><br> | ||

===[[image:Check.jpg|25px]] ENHANCE - Adjust General Dynamic Option Name - Feed-Bend Torque Limits === | ===[[image:Check.jpg|25px]] ENHANCE - Adjust General Dynamic Option Name - Feed-Bend Torque Limits === | ||

| Line 24: | Line 31: | ||

<br><br> | <br><br> | ||

| + | |||

| + | |||

| + | ===[[image:Check.jpg|25px]] ENHANCE - Upper Torque Limit No Longer Applies to Manual Feed Moves === | ||

| + | |||

| + | The upper torque limit in Low Level general dynamic options is no longer used to warn for manual feed moves using high torque. This value is intended only for Feed-Bend motion. | ||

| + | <br><br> | ||

| + | <br><br> | ||

| + | |||

| + | === WARNING: Be Careful to Set Proper Torque Limits === | ||

<br> | <br> | ||

<table cellpadding="15"> | <table cellpadding="15"> | ||

| − | <tr><td | + | <tr> |

| + | <td>[[image:warning.jpg|100px]]</td> | ||

<td width=300 bgcolor="#f0f0f0"> | <td width=300 bgcolor="#f0f0f0"> | ||

| − | <font size=5>[[image:Gear_warning.jpg]] <b> | + | <font size=5>[[image:Gear_warning.jpg]] <b>WARNING!</b><br><br></font> |

| − | <font size=3>'''Do not''' set the HIGH value to any value above the | + | <font size=3>'''Do not''' set the HIGH value to any value above the recommended value - or the Feed Axis gear box or other parts of the carriage or carriage motion system could be damaged by high settings in the Bender Data page.<br><br> |

| − | "25%" is typically the maximum | + | "25%" is typically the maximum recommended value for extended-run.<br><br> |

Any higher value may damage the machine and possibly void the warranty. | Any higher value may damage the machine and possibly void the warranty. | ||

</font></td></tr></table> | </font></td></tr></table> | ||

| + | |||

| + | |||

| + | <table cellpadding="15"> | ||

| + | <tr> | ||

| + | <td>[[image:warning.jpg|100px]]</td> | ||

| + | <td width=300 bgcolor="#f0f0f0"> | ||

| + | <font size=5>[[image:Gear_warning.jpg]] <b>WARNING!</b><br><br></font> | ||

| + | <font size=3>'''Do not''' set the LOW value to any value below the recommended value - or the Feed Axis gear box or other parts may run-away due to high-errors.<br><br> | ||

| + | "10%" is typically the minimum recommended value for extended-run.<br><br> | ||

| + | Any lower value may damage the machine and possibly void the warranty. | ||

| + | </font></td></tr></table> | ||

| + | |||

| + | ===[[image:Check.jpg|25px]] ENHANCE - Immediate Messages are Limited to ONE Message Per Event === | ||

| + | |||

| + | |||

| + | |||

| + | <table> | ||

| + | <tr> | ||

| + | <td width="300"> | ||

| + | When the CNC Processor sends a collision error message back to CNC Bender, the Immediate Message box displays with the message. | ||

| + | <br><br> | ||

| + | In previous versions, it was possible that multiple messages would be sent until a time-out occurred in a move. This has been changed in this version so that one message is returned and the process is HALTED. | ||

| + | <br><br> | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:cncbender_immediatemessage.jpg|300px]] | ||

| + | </td> | ||

| + | </tr> | ||

| + | </table> | ||

| + | |||

| + | <br><br> | ||

=Other Pages= | =Other Pages= | ||

Latest revision as of 21:24, 26 September 2009

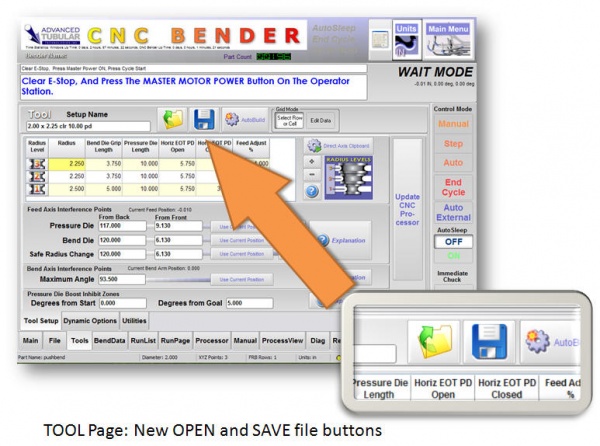

NEW - SAVE and OPEN Tool Set Files from the Tool Page

NEW - SAVE and OPEN Tool Set Files from the Tool Page

The tool page now has open and save buttons for TOOL SET FILE management in CNC Bender.

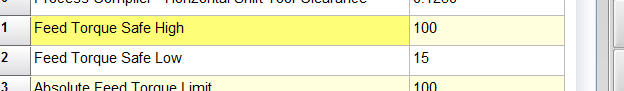

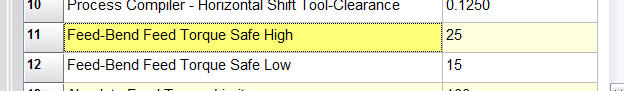

ENHANCE - Adjust General Dynamic Option Name - Feed-Bend Torque Limits

ENHANCE - Adjust General Dynamic Option Name - Feed-Bend Torque Limits

The Low Level names of dynamic options "Feed Torque Safe High" and "Feed Torque Safe Low" were adjusted for clarification.

The new names include "Feed-Bend" inserted in the beginning to be sure users understand that these values are used by the Processlist Builder to limit the feed axis torque during Feed-Bending only. These values have no effect on the torque of the feed axis for any other type of feed motion.

These are the options before the change:

These are the options after the change:

Upgrade Note: When upgrading to this version, it is important to remember to restore the dynamic options in low level in order to see this change take effect.

ENHANCE - Upper Torque Limit No Longer Applies to Manual Feed Moves

ENHANCE - Upper Torque Limit No Longer Applies to Manual Feed Moves

The upper torque limit in Low Level general dynamic options is no longer used to warn for manual feed moves using high torque. This value is intended only for Feed-Bend motion.

WARNING: Be Careful to Set Proper Torque Limits

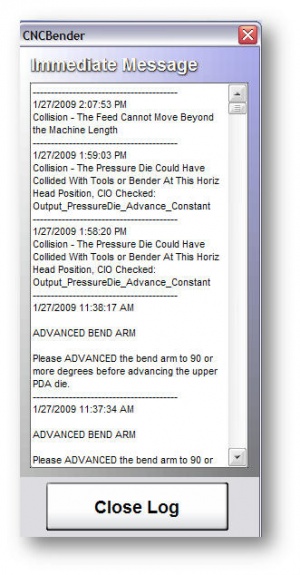

ENHANCE - Immediate Messages are Limited to ONE Message Per Event

ENHANCE - Immediate Messages are Limited to ONE Message Per Event

|

When the CNC Processor sends a collision error message back to CNC Bender, the Immediate Message box displays with the message.

|

Other Pages

- Back to CNC Bender

- Back to CNC Bender Software Updates

- Read about Push Bending

- Read about Push Bend Profile Tables