Difference between revisions of "CNC Bender v11-20081009"

| Line 29: | Line 29: | ||

We've changed the wording of the PD BOOST to PD ASSIST in CNC Bender to more accurately reflect what the feature is in CNC Bender.<br><br> | We've changed the wording of the PD BOOST to PD ASSIST in CNC Bender to more accurately reflect what the feature is in CNC Bender.<br><br> | ||

[[image:cncbender_pda_assist_options.jpg|500px]] | [[image:cncbender_pda_assist_options.jpg|500px]] | ||

| + | <br><br> | ||

| + | |||

| + | |||

| + | ===[[image:Check.jpg|25px]] NEW - XYZ REVERSE === | ||

| + | |||

| + | A new Reverse XYZ feature allows you to reverse the XYZ data on the screen.<br><br> | ||

| + | [[image:cncbender_reverse_xyz.jpg|500px]] | ||

<br><br> | <br><br> | ||

Revision as of 01:25, 10 October 2008

CHANGES to CNC BENDER

NEW - Recent Parts List

NEW - Recent Parts List

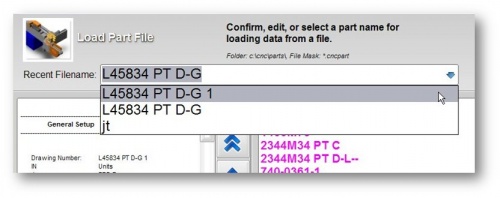

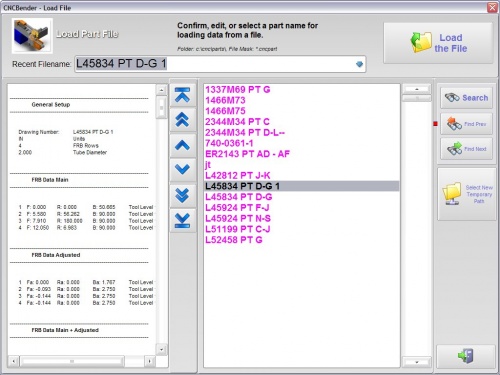

Operators asked us to include a recent part file list in the CNC Bender File Load menu. So the feature has been added in this version.

The list is placed at the top of the file load menu and tracks the last 20 unique part names loaded into CNC Bender. To use the list:

- Pull down the list using the down arrow

- Select the part to reload

- The part will be searched for and selected in the parts list (if it is still in the list)

- Press Load

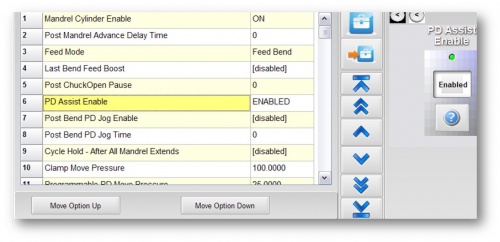

REVISED - PD BOOST Changed to PD ASSIST

REVISED - PD BOOST Changed to PD ASSIST

We've changed the wording of the PD BOOST to PD ASSIST in CNC Bender to more accurately reflect what the feature is in CNC Bender.

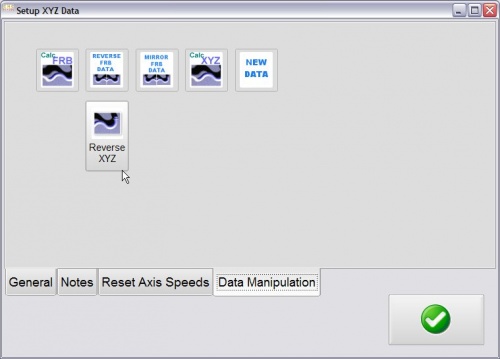

NEW - XYZ REVERSE

NEW - XYZ REVERSE

A new Reverse XYZ feature allows you to reverse the XYZ data on the screen.

CHANGES to CNC PROCESSOR

Repair To Inline Edge Trigger Logic

Repair To Inline Edge Trigger Logic

A logic problem with the Edge Trigger conditional inline handling introduced in the previous version is repaired and enhanced.

Updating to this version from the previous version is important to solve issues with the pressure die boost return input and the run button inputs.

NEW - Run Button Anti-Tie-Down Logic Always Handled Internally by CNC Processor

NEW - Run Button Anti-Tie-Down Logic Always Handled Internally by CNC Processor

Edge Trigger logic is used to require a button to be released then pressed before it is considered activated. This is usually applied where it is unsafe to allow a button to be continuously pressed (without release) for machine operation.

Run button inputs require special handling with Edge Trigger logic, so if Edge Trigger logic is enabled for either the left or right run button inputs, then CNC Processor ignores the "require edge trigger" setting for those two inputs so that the anti-tie down logic is handled internally.

If the "require edge trigger" is set to ON in either of these inputs in the CIO dictionary, then Processor will report in the log when CNC Bender is loaded. The message displayed in the log will be:

Run Button Edge Triggers Are Switched OFF - Handling Internally in CNC Processor

Other Pages

- Back to CNC Bender

- Back to CNC Bender Software Updates

- Read about Push Bending

- Read about Push Bend Profile Tables