|

|

| Line 3: |

Line 3: |

| | <td bgcolor="#FFFFFF"><font size=3> For over 8 years, we've offered the most flexible CNC Bender software available anywhere. <b>We're the TUBE FABRICATION CNC BENDER SPECIALISTS.</b> (See why below.) </font><br><br> | | <td bgcolor="#FFFFFF"><font size=3> For over 8 years, we've offered the most flexible CNC Bender software available anywhere. <b>We're the TUBE FABRICATION CNC BENDER SPECIALISTS.</b> (See why below.) </font><br><br> |

| | [[image:cncbender_logo.jpg|400px|center]]<br> | | [[image:cncbender_logo.jpg|400px|center]]<br> |

| | + | Did you know...<br> |

| | [[image:cncbender_axisexpansion_logo.jpg|400px]]<br><br> | | [[image:cncbender_axisexpansion_logo.jpg|400px]]<br><br> |

| | </td> | | </td> |

Revision as of 19:51, 27 September 2008

For over 8 years, we've offered the most flexible CNC Bender software available anywhere. We're the TUBE FABRICATION CNC BENDER SPECIALISTS. (See why below.)

Did you know...

|

|

| Description |

CNC Bender is the most flexible software system for controlling horizontal draw benders and push-benders anywhere. This software has been developed in partnership with SMT Industries of Sidney, Ohio. The original version release was in 2000. It is marketed exclusively through SMT Industries |

This is a SAMPLE of Unique Features

|

| The Most Rapid Integration - Anywhere |

CNC Bender is designed to integrate to a highly diverse set of bender types. Flexibility and rapid setup is unparalleled. No other other bender control on the market can adapt so quickly to a new bender or add new features so easily.

Here's an example: Need to add another motion-controlled axis? A new axis - including complete functionality, can be added to CNC Bender in a couple of days.

|

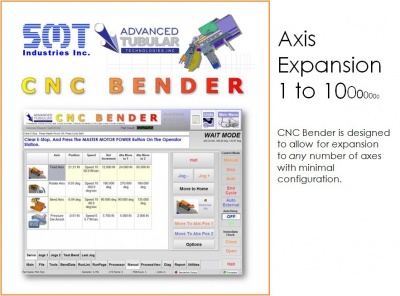

| Unlimited Axis Expansion to 4, 5, 6 even 30 axes! |

CNC Bender is designed to something never before possible on any CNC Bender controls: Easily expand to ANY number of motion-controlled axes. Can it handle 15? No Problem. How about 30?! Can do. See our Axis Expansion page for details on how CNC Bender is designed to handle any number of axes.

|

|

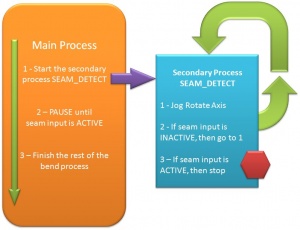

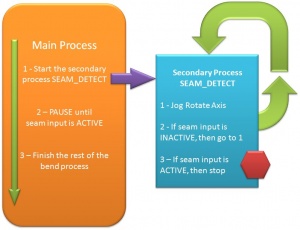

| Unlimited Multitasking Background Processes |

CNC Bender is the only bender software that can run an unlimited number of multi-tasked background tasks while bending tube. For example, CNC Bender can be setup to run a hopper with tube detect, seam detect, hopper motion, grippers, transfer, etc. No PLCs needed.

|

Dynamic Options |

We pioneered the Dynamic Option concept. Dynamic options allow users to control the setup - but with extreme display flexibility: Make unused options invisible or disabled. Bring the most-used options to to the top of the list. Re-arrange the option controls for left or right-handed users. Click on this diagram to see a sample dynamic option.

|

|

Robots Can Choose the Next Part to Fabricate |

CNC Bender is so powerful it can listen to your robot's command to choose another part - by name automatically to bend in the bender. CNC Bender switches to the new part, receives the part from the robot in the correct loading position, bends the part, then notifies the robot that it is finished with a part-name confirmation that it is holding the new part for removal. Click on the diagram for an illustration of how this works. |

|

Correct Push-Bent Parts With a Measuring Center |

Using Benderlink, CNC Bender can apply measuring center corrections to bend angles made through push-bending. (This applies to flat push-bends only - not coiled bends. Supravision is not designed to handle true coils.) Click on this diagram for a Benderlink illustration |

|

PDA-RVG = Real-time Variable Gearing for the Pressure Die Assist |

CNC Bender can control the Pressure Die Assist as an axis that is geared to the bend axis. But it can do way more than just use a gear ratio.

Our "RVG" feature (which means "Real-time Variable Gearing") allows you to change the gearing in real-time at any bend angle. We even allow you to add a unique RVG profile setup to each bend (not just the entire bend program. |  |

| Controlled Jog OR Direct Axis Jog |

We pioneered the controlled jog concept. Controlled jog is a small bend program that moves the axis a programmed distance at a programmed velocity. But we also allow you to perform direct axis jogs. Direct axis jogs allow to move the axes by holding down a button. When the button is released, the jogging stops. |

|

| Built-in Seam Detection Logic |

Seam detection is a built-in process that is configurable for use with any seam detection device. Our benders' even rotate the tube in the ROTATE axis spindle for the seam detection device. No rotation devices or PLCs required. Read more about Seam Detection Logic here. |

|

|

More Information About CNC Bender

License Types

CNC Bender License Types

Video

CNC Bender Video Page

SMT / Advanced Tubular Technologies - Technology Alliance

CNC Bender Technology Alliance

SMT Industries Advertising

FAQ

CNC Bender FAQ Page

Tutorials

CNC Bender Tutorials Page

CNC Bender Technical Notes

General Information

CNC Bender General Information Page

Robot Integration

CNC Bender Robot Integration page

Seam Detection Integration

Seam Detection Logic page

Software Updates and Modifications

CNC Bender Software Updates Page

CNC Bender Upgrade Policy Page

CNC Bender Custom Modifications Page

CNC Bender Upgrade page

SMT Benders Image