Difference between revisions of "CNC Bender"

| Line 8: | Line 8: | ||

<table width=500> | <table width=500> | ||

<tr> | <tr> | ||

| − | <td width="75" bgcolor="# | + | <td width="75" bgcolor="#3366CC">Description</td> |

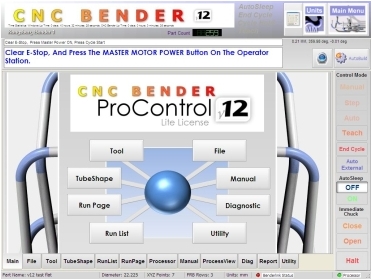

<td>CNC Bender is a software system for controlling horizontal '''draw benders''' and '''push-benders'''. This software has been developed in partnership with [[SMT Industries]] of Sidney, Ohio. The original version release was in 2000. It is marketed exclusively through [[SMT Industries]]</td> | <td>CNC Bender is a software system for controlling horizontal '''draw benders''' and '''push-benders'''. This software has been developed in partnership with [[SMT Industries]] of Sidney, Ohio. The original version release was in 2000. It is marketed exclusively through [[SMT Industries]]</td> | ||

| Line 14: | Line 14: | ||

<tr> | <tr> | ||

| − | <td width="75" bgcolor="# | + | <td width="75" bgcolor="#3366CC"> Unique Features</td> |

<td> | <td> | ||

Revision as of 16:51, 15 August 2008

| Description | CNC Bender is a software system for controlling horizontal draw benders and push-benders. This software has been developed in partnership with SMT Industries of Sidney, Ohio. The original version release was in 2000. It is marketed exclusively through SMT Industries | ||||||||

| Unique Features |

|

License Types

Movies

CNC Bender Movies Page

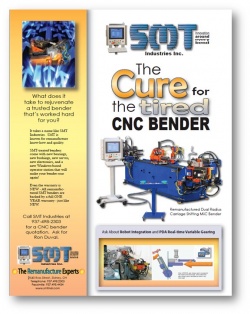

Advertising for CNC Bender

FAQ

CNC Bender FAQ Page

Tutorials

CNC Bender Tutorials Page

CNC Bender Technical Notes

General Information

CNC Bender General Information Page

Robot Integration

CNC Bender Robot Integration page

Software Updates and Modifications

CNC Bender Software Updates Page

CNC Bender Upgrade Policy Page

CNC Bender Custom Modifications Page

CNC Bender Upgrade page