321 Plane Line Point Aligment

|

|

Contents |

What is Alignment?

|

"Alignment" refers to the process where the measured tube is being aligned to the master tube. |

321 Plane Line Point

|

The alignment is pronounced "three two one plane line point".

|

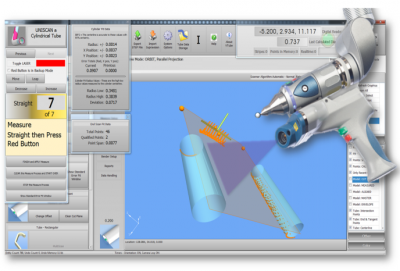

Illustration of how 321 PLP WorksThe 321 Plane Line Point alignment method is much less sophisticated than the other iterative Best Fit aligment algorithms.

|

Visually Demonstrate the Problem of Qualifying with Angles

|

Unless you can perform 3D trigonometry mentally on-the-fly, the answer to the question above isn't obvious. Even if we guess the answer, we can not accurately guess at what tolerance envelope value the part would be considered acceptable. |

|

This second alignment image shows the part with IDENTICAL ANGLES - but the two middle straights are lengthened to 10 inches between bends. |

The Best Data for Qualification

|

The best data for qualification is centerline TANGENT POINT and MIDPOINT data in the Inspection Data menu and in the Reports menu. |