Difference between revisions of "Push Bending Profile Table"

From ATTWiki

(→About) |

(→Description of Values) |

||

| Line 24: | Line 24: | ||

<td></td> | <td></td> | ||

<td bgcolor="#d3e0f7"><b>Profile Name</b></td> | <td bgcolor="#d3e0f7"><b>Profile Name</b></td> | ||

| − | <td bgcolor="#f7ebc3">The name is how the profile is displayed and selected in the Bend Options.</td> | + | <td bgcolor="#f7ebc3"><br><br>The name is how the profile is displayed and selected in the Bend Options.<br><br></td> |

</tr> | </tr> | ||

| Line 30: | Line 30: | ||

<td></td> | <td></td> | ||

<td bgcolor="#d3e0f7"><b>Arm Angle</b></td> | <td bgcolor="#d3e0f7"><b>Arm Angle</b></td> | ||

| − | <td bgcolor="#f7ebc3">This is the final angle of the arm during push-bending.</td> | + | <td bgcolor="#f7ebc3"><br><br>This is the final angle of the arm during push-bending.<br><br></td> |

</tr> | </tr> | ||

| Line 36: | Line 36: | ||

<td></td> | <td></td> | ||

<td bgcolor="#d3e0f7"><b>Arm vAdjust</b></td> | <td bgcolor="#d3e0f7"><b>Arm vAdjust</b></td> | ||

| − | <td bgcolor="#f7ebc3">This allows the velocity of the bend arm to be adjusted by a percentage of the original calculated velocity.</td> | + | <td bgcolor="#f7ebc3"><br><br>This allows the velocity of the bend arm to be adjusted by a percentage of the original calculated velocity.<br><br></td> |

</tr> | </tr> | ||

| Line 42: | Line 42: | ||

<td></td> | <td></td> | ||

<td bgcolor="#d3e0f7"><b>Arm vAdjust</b></td> | <td bgcolor="#d3e0f7"><b>Arm vAdjust</b></td> | ||

| − | <td bgcolor="#f7ebc3">This allows the velocity of the bend arm to be adjusted by a percentage of the original calculated velocity.</td> | + | <td bgcolor="#f7ebc3"><br><br>This allows the velocity of the bend arm to be adjusted by a percentage of the original calculated velocity.<br><br></td> |

</tr> | </tr> | ||

| Line 48: | Line 48: | ||

<td></td> | <td></td> | ||

<td bgcolor="#d3e0f7"><b>Feed Position</b></td> | <td bgcolor="#d3e0f7"><b>Feed Position</b></td> | ||

| − | <td bgcolor="#f7ebc3">This is how far the carriage must travel to achieve the "@ Degrees" value.</td> | + | <td bgcolor="#f7ebc3"><br><br>This is how far the carriage must travel to achieve the "@ Degrees" value.<br><br></td> |

</tr> | </tr> | ||

| Line 54: | Line 54: | ||

<td></td> | <td></td> | ||

<td bgcolor="#d3e0f7"><b>Feed Velocity</b></td> | <td bgcolor="#d3e0f7"><b>Feed Velocity</b></td> | ||

| − | <td bgcolor="#f7ebc3">This is the velocity of the carriage during the bend. The velocity of the carriage is used to calculate a starting bend arm motion speed.</td> | + | <td bgcolor="#f7ebc3"><br><br>This is the velocity of the carriage during the bend. The velocity of the carriage is used to calculate a starting bend arm motion speed.<br><br></td> |

</tr> | </tr> | ||

| Line 60: | Line 60: | ||

<td></td> | <td></td> | ||

<td bgcolor="#d3e0f7"><b>@ Degrees</b></td> | <td bgcolor="#d3e0f7"><b>@ Degrees</b></td> | ||

| − | <td bgcolor="#f7ebc3">This is the angle of the tube that is achieved by the "Feed Position" value above.</td> | + | <td bgcolor="#f7ebc3"><br><br>This is the angle of the tube that is achieved by the "Feed Position" value above.<br><br></td> |

</tr> | </tr> | ||

</table> | </table> | ||

Revision as of 16:56, 25 April 2008

About

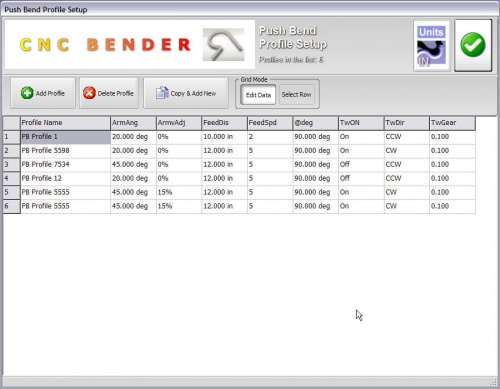

This is a sample Push Bend Profile Table. Each profile row contains a profile setup for a given radius. An unlimited number of profile values can be entered. Using this method of calculation, it is possible to calculate different Push Bends by indicating the new bend angles.

Because we use this method of calculation, it is possible to correct push bent parts using measuring center connections. Correct the bend value, and the push bend values are automatically calculated during AutoBuild.

Description of Values

This is a description of each value in the Profile Table:

| Value Name | Description | |

| Profile Name | The name is how the profile is displayed and selected in the Bend Options. |

|

| Arm Angle | This is the final angle of the arm during push-bending. |

|

| Arm vAdjust | This allows the velocity of the bend arm to be adjusted by a percentage of the original calculated velocity. |

|

| Arm vAdjust | This allows the velocity of the bend arm to be adjusted by a percentage of the original calculated velocity. |

|

| Feed Position | This is how far the carriage must travel to achieve the "@ Degrees" value. |

|

| Feed Velocity | This is the velocity of the carriage during the bend. The velocity of the carriage is used to calculate a starting bend arm motion speed. |

|

| @ Degrees | This is the angle of the tube that is achieved by the "Feed Position" value above. |