Difference between revisions of "CNC Bender v12-20100820"

| (22 intermediate revisions by one user not shown) | |||

| Line 8: | Line 8: | ||

</tr> | </tr> | ||

</table> | </table> | ||

| + | ===[[image:Check.jpg|25px]] NEW - SERVO CONTROLLED Vertical Head Axis === | ||

| + | <table> | ||

| + | <tr valign=top> | ||

| + | <td width=200> | ||

| + | Now servo-control the vertical head axis to any radius stack level.<br><br> | ||

| + | [[image:radlevels.jpg]] [[image:verticalheadshift_manualpage.jpg]] | ||

| − | + | </td> | |

| + | <td> | ||

| + | </td> | ||

| + | </tr> | ||

| + | |||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | |||

| + | </td> | ||

| + | <td> | ||

| + | </td> | ||

| + | </tr> | ||

| + | </table> | ||

| + | <br><br> | ||

===[[image:Check.jpg|25px]] NEW - Servo Status Grid Now Always Visible on Main Screen === | ===[[image:Check.jpg|25px]] NEW - Servo Status Grid Now Always Visible on Main Screen === | ||

| Line 41: | Line 60: | ||

For important events, CNC Bender now displays large messages for short periods of time.<br><br> | For important events, CNC Bender now displays large messages for short periods of time.<br><br> | ||

| − | This | + | This gives operators large, clear, and friendly messages of what step needs to be taken next. |

<br><br> | <br><br> | ||

[[image:cncbender_bigmessage_PressRunButton.jpg|300px]]<br> | [[image:cncbender_bigmessage_PressRunButton.jpg|300px]]<br> | ||

| Line 58: | Line 77: | ||

</table> | </table> | ||

| − | + | ===[[image:Check.jpg|25px]] NEW - Can Require ENABLE Button Press to Jog === | |

| − | + | ||

| − | ===[[image:Check.jpg|25px]] NEW - | + | |

<table> | <table> | ||

<tr valign=top> | <tr valign=top> | ||

<td width=200> | <td width=200> | ||

| − | Some | + | Some customers require that the operator press the ENABLE button to Jog.<br><br> |

<br><br> | <br><br> | ||

[[image:cncbender_bigmessage_EnablePlusJoyStick.jpg|250px]]<br> | [[image:cncbender_bigmessage_EnablePlusJoyStick.jpg|250px]]<br> | ||

| Line 85: | Line 102: | ||

</table> | </table> | ||

| − | + | ===[[image:Check.jpg|25px]] ENHANCED - CNC Processor CPU Usage DECREASED to 25% === | |

| − | + | ||

| − | ===[[image:Check.jpg|25px]] ENHANCED - CNC Processor CPU Usage DECREASED | + | |

<table> | <table> | ||

<tr valign=top> | <tr valign=top> | ||

<td width=200> | <td width=200> | ||

| − | CNC Bender was optimized so that CNC Bender / CNC Processor CPU Usage was dropped | + | CNC Bender was optimized so that CNC Bender / CNC Processor CPU Usage was dropped from 75%-80% down to 25% ''or lower'' without any degradation in bender performance. The typical CPU usage under load rarely spikes beyond 35%. |

<table> | <table> | ||

| Line 133: | Line 148: | ||

<tr valign=top> | <tr valign=top> | ||

<td width=200> | <td width=200> | ||

| − | [[image: | + | [[image:operatorstation_key.jpg|250px]]<br> |

<br> | <br> | ||

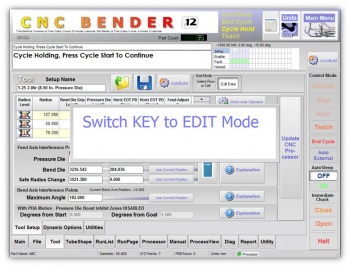

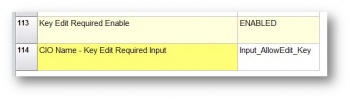

CNC Bender can now be setup in Low Level to require that a Key be inserted and switched to the EDIT mode on an operator station to allow an operator to edit data on the screen. | CNC Bender can now be setup in Low Level to require that a Key be inserted and switched to the EDIT mode on an operator station to allow an operator to edit data on the screen. | ||

| Line 155: | Line 170: | ||

</tr> | </tr> | ||

</table> | </table> | ||

| + | |||

| + | |||

<br><br> | <br><br> | ||

| Line 247: | Line 264: | ||

<tr valign=top> | <tr valign=top> | ||

<td width=300> | <td width=300> | ||

| − | The image on the right is a screen shot of Smart Inspect logging from a CNC Processor session | + | The image on the right is a screen shot of Smart Inspect logging from a CNC Processor session. |

| − | <br> | + | <br><br> |

| − | + | The new feature allows CNC Bender technicians to track performance inside CNC Processor through the network. Process times are returned as finely graded as microseconds - allowing us to track and fine-tune bottlenecks out of the process. | |

</td> | </td> | ||

<td> | <td> | ||

| Line 277: | Line 294: | ||

<br><br> | <br><br> | ||

| + | ===[[image:Check.jpg|25px]] NEW - Soft EOT for Each Axis === | ||

| − | + | <table cellpadding=10> | |

| − | + | ||

| − | <table> | + | |

<tr valign=top> | <tr valign=top> | ||

<td width=200> | <td width=200> | ||

| Line 304: | Line 320: | ||

High EOT=3160</pre> | High EOT=3160</pre> | ||

| + | </td> | ||

| + | </tr> | ||

| + | |||

| + | <tr valign=top> | ||

| + | <td width=200> | ||

| + | When the axis arrives at the programmed EOT, a Big Message (see above) displays on the screen that announces that the axis has arrived at the axis EOT - and CNC Processor stops the axis motion. | ||

</td> | </td> | ||

</tr> | </tr> | ||

Latest revision as of 00:07, 1 September 2010

NEW - SERVO CONTROLLED Vertical Head Axis

NEW - SERVO CONTROLLED Vertical Head Axis

|

Now servo-control the vertical head axis to any radius stack level. |

|

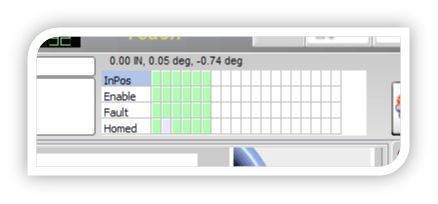

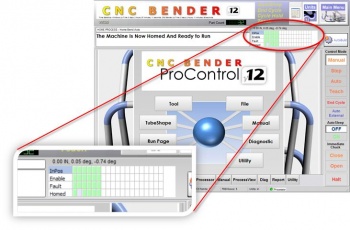

NEW - Servo Status Grid Now Always Visible on Main Screen

NEW - Servo Status Grid Now Always Visible on Main Screen

|

The status of up to 20 servo axes are now displayed at all times in a grid on the top of the screen. |

|

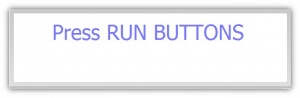

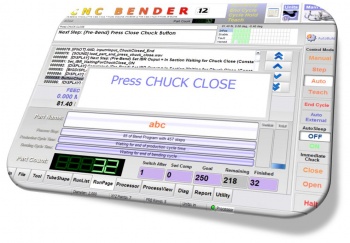

NEW - BIG Messages

NEW - BIG Messages

|

For important events, CNC Bender now displays large messages for short periods of time. This gives operators large, clear, and friendly messages of what step needs to be taken next.

|

|

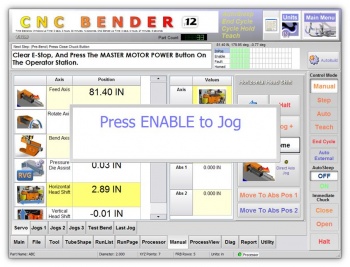

NEW - Can Require ENABLE Button Press to Jog

NEW - Can Require ENABLE Button Press to Jog

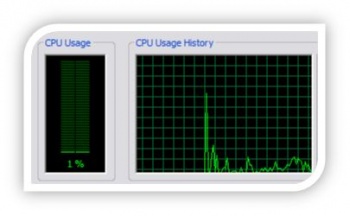

ENHANCED - CNC Processor CPU Usage DECREASED to 25%

ENHANCED - CNC Processor CPU Usage DECREASED to 25%

|

CNC Bender was optimized so that CNC Bender / CNC Processor CPU Usage was dropped from 75%-80% down to 25% or lower without any degradation in bender performance. The typical CPU usage under load rarely spikes beyond 35%.

Note: This optimization causes the CNC Bender user interface to run much more quickly. |

|||||

NEW - KEY Switch to EDIT Feature

NEW - KEY Switch to EDIT Feature

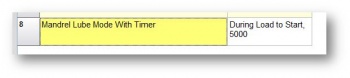

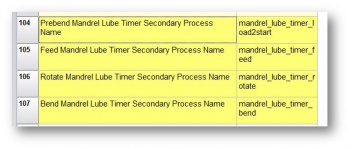

NEW - MANDREL LUBE with TIMER in FOUR OPTION LISTS

NEW - MANDREL LUBE with TIMER in FOUR OPTION LISTS

|

The new Mandrel Lube With Timer option allows operators to lube the mandrel for a period of milliseconds

|

|

|

Setup the feature in the low level menu - general dynamic options by naming the secondary process list names:

|

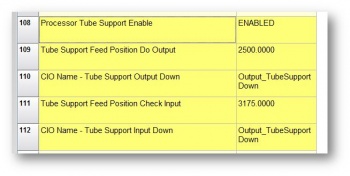

NEW - EMBEDDED TUBE SUPPORT in CNC PROCESSOR

NEW - EMBEDDED TUBE SUPPORT in CNC PROCESSOR

|

This feature allows CNC Bender's PROCESSOR to control when the tube support is lifted or dropped - and if the drop should be confirmed with an input.

|

|

CHANGES - CNC Processor Configuration File

CHANGES - CNC Processor Configuration File

|

The following additions have been made to the configuration file:

|

ADD these to the CNCProcessor.cfg file: [Smart Inspect Logging] Enabled=0 Logging Method=TCPIP Filename=c:\cnc\logs\cncprocessor.sil TCPIP Address=192.168.0.190 [Loop] Main Loop Interval=0.100 Background Read Servo Loop Interval=0.100 |

|

The image on the right is a screen shot of Smart Inspect logging from a CNC Processor session.

|

|

|

The items on the right can be removed from the configuration file. They are no longer used in CNC Processor. |

REMOVE these from the CNCProcessor.cfg file: [Loop] Power Off Manual Mode Pause=250 Power On Manual Mode Pause=250 Cycle Hold Pause=100 [PRIORITY] Master Loop Priority=10000 |

NEW - Soft EOT for Each Axis

NEW - Soft EOT for Each Axis

|

During JOGGING - CNC Processor can check for EOT (end of travel) of an axis before it arrives at the true FAULT EOT. This gives the axis a chance to stop jogging before it arrives at a FAULT position or emergency switch.

|

The following additions have been made to the AXIS configuration file:

Example of what to add in each AXIS in the main.axislist file. The value shown here are typical of the FEED axis: Enable EOT=1 Low EOT=0 High EOT=3160 |

|

When the axis arrives at the programmed EOT, a Big Message (see above) displays on the screen that announces that the axis has arrived at the axis EOT - and CNC Processor stops the axis motion. |

Other Pages

- Back to CNC Bender

- Back to CNC Bender Software Updates

- See CNC Bender General Information

- See Teach Mode

- See Custom Commands